Simple calculation

It would seem, based on school knowledge, nothing is simpler. Having found out the length, height and width of a log or beam, you can simply multiply and get the result of the dimensions of a wooden box. However, the diameter of the material must not be overlooked; it directly affects the final figure and width of the compensation cut, which leaves the original size of the logs, but significantly reduces the amount of wood.

It becomes clear that calculating the volume of a log house is not a very simple matter, especially taking into account the methods of connecting the corners - with and without the remainder. But still feasible. So, we have the desired size 6×6 and using this example we will analyze the required quantity:

- First of all, you need to understand that a larger diameter of logs will ultimately be a plus in the overall cost of money. After all, a built house will cost with a smaller layer of insulation, or even without it at all.

Thus, it becomes clear that construction must be carried out using logs with a diameter of 26 cm and above. So - the first known size is diameter = 0.26 mm.

- Next, the height of the log house. It is impossible to calculate the frame for a house without taking into account the height. Usually it is 2.4 m per floor in the pure internal version.

But let’s take an external height of 3 m as the required quantity. Now it’s not difficult to calculate the logs for one wall - 3/0.26 = 11.5 pcs. Round up to 12 and add the base crown element. Total number of logs per wall = 13 pcs.

- Now let's make calculations for all the walls of the log house. Let's take a five-wall structure as an example, since the lengths of the sides are the same, it is not difficult to calculate a log house by the number of logs - 13 × 5 = 65 pieces. That is, to build a 6x6 house with a log diameter of 26 cm, 65 logs will be required.

But the material is not purchased individually. For this there is such a measure as volume. Of course, you can go to a sawmill and point your finger at the logs to indicate what material is needed, but it will look more than strange.

- Using the well-known school formula - π*R²*L, we find the volume of one log. Multiplying the data - where R is the radius of the deck, and L is the length, we get the result 0.32 m³.

It is now easy to calculate the cubic capacity of the entire log house - 0.32*65=20.8 m³. That is, for a 6x6 house, a one-story five-wall building, 3 m high, approximately 21 m³ of forest will be required.

Now, by assessing the offers on the market of lumber production companies, you can understand whether the average family can handle solid wood construction. The proposed option is a large house, even one floor high.

To this should be added the costs of the foundation, rafter system and finishing, which together can increase the project amount by more than 2 times. By the way, you can calculate a log house using the example given, and its cost is lower than a log.

Table of cubic capacity calculations for material of different diameters

To make complex calculations easier for users, here is a table of ready-made cubic capacity calculations for a certain array diameter:

| Log diameter | Log volume m³ at different lengths of logs | |||||||

| 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | |

| 20 | 0.107 | 0.126 | 0.147 | 0.170 | 0.190 | 0.210 | 0.230 | 0.260 |

| 22 | 0.130 | 0.154 | 0.178 | 0.200 | 0.230 | 0.250 | 0.280 | 0.310 |

| 24 | 0.157 | 0.184 | 0.210 | 0.240 | 0.270 | 0.300 | 0.330 | 0.360 |

| 26 | 0.185 | 0.210 | 0.250 | 0.280 | 0.320 | 0.350 | 0.390 | 0.430 |

| 28 | 0.220 | 0.250 | 0.290 | 0.330 | 0.370 | 0.410 | 0.450 | 0.490 |

It is important that everything that exceeds the presented length and volume should be left to specialists, because the construction of such logs cannot be done without the use of special equipment, and, therefore, it is much cheaper and faster to entrust the work to professionals by ordering a turnkey log house from the company. Before concluding a contract, you can ask the company manager how cubic capacity is calculated.

Answering all the client’s questions is his sacred duty. Perhaps the knowledge gained will serve as support for independent construction of an object other than a residential building.

Foundation

This is a mandatory stage of construction. Since the bathhouse is a relatively light structure, it can be done without a permanent foundation. However, you can’t do without it completely.

When choosing a location for the foundation, it is very important to take into account the condition of the soil. Ideal for construction, dense and dry

But such luck is rare, and therefore it is worth taking into account the composition of the soil and the proximity of groundwater. Depending on these factors, the most suitable foundation for a particular case is selected.

Most often, a strip foundation is laid, the height of which is at least 0.5 m and the width is 0.3 m. It is suitable for installation on any soil. However, there is much more hassle with it than with other types: it takes longer to install, excavation and additional work is required before its construction.

We suggest you familiarize yourself with How to properly clean a pipe in a bathhouse from soot and soot with your own hands

But this is not the only option: you can also install the structure on the piles of a screw foundation. This is a very strong base that can support even a two-story building and can easily handle its weight.

And the third option: a columnar foundation, on which it is just right to install a light bathhouse.

A drainage hole for the sewer pipe is dug two meters from the foundation. The pipe itself is laid in a trench specially dug for this purpose.

Calculation for a bath

To build your own steam room, you do not need to resort to the services of specialists - calculating the frame of a bathhouse yourself will not be difficult.

A typical 3x5 project will take a little time to construct and such a structure will consist of functional premises - nothing superfluous, but amenities are not lost.

So this is:

- Steam room.

- Washing room.

- Waiting room.

Based on the wishes of everyone at home, the steam room and washing room can be combined. Thus, there is no need for one wall.

But you should take into account the health characteristics of all visitors to the bathhouse - perhaps someone cannot tolerate steam. And washing at a constant temperature is not a very pleasant experience even for avid lovers of the Russian bath.

How to properly insulate crowns.

Although you can often hear that a good option for insulating crowns is polyurethane foam, in fact it is not advisable to use it. This is a rather expensive product, but that’s not the point, it’s that the foam is susceptible to the harmful effects of ultraviolet radiation and moisture. As a result, it collapses and turns yellow.

It is enough to go to a specialized store to make sure that on the shelves there are many different insulation materials specifically for wooden buildings. A good choice would be tape insulation - jute. The technology involves rolling it onto a beam and then fastening it with nails or a stapler.

Recommendations from experts

The problem of how to calculate a log house for a house can be solved quite easily using the above material and formulas. But you shouldn’t delude yourself and talk about the obtained figures as specific ones - you’ll have to take into account window and door openings, but not immediately, in order to subtract them from the total, but accept them as a proper expense. Otherwise, it will turn out that the array will have to be purchased again.

There is also a risk of purchasing substandard raw materials - damage, knots, wormholes - all this will further affect the amount of money spent. Remember that even rich and wealthy clients cannot afford to throw money away, so they use the working rule - you cannot skimp on quality.

It is possible to design a house from a smaller log frame than to build a castle out of anything, relying only on cheapness. Its operation will be accordingly.

Konstantin Shcherbakov

Author of publications on 1Drevo.ru with the topics: Ventilation valves for PVC windows | Round house | Rounded timber | Bathhouse 6 by 4 | Finnish houses | Bathhouse with gazebo | Installation of log house | Pellet boilers | Solid fuel boiler | Electric boiler in the house | Heat pump | Painting laminated timber | Solid timber house | Panel house | Manual felling of a log house | Foundation insulation | House kit made of laminated veneer lumber and others.

Collections of publications on topics:

Cubic capacity table Lumber for construction

Was this publication useful to you?

Bookmark it on social networks!

Total score: 5Votes: 8

Why hand-cut log houses are valued - traditional log making

Options and methods for exterior finishing of a house made of timber

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

How to weld a canopy from a profile pipe near a house

Layout of a house made of timber 200 square meters

One-story and two-story houses made of timber measuring 12 by 12

Combination of different styles when building a house from timber

Features and differences of drawings of houses made of timber

Classic log size 6 by 6 for building a house

Calculation of house construction on a calculator

This calculator allows you to calculate the cost of building a turnkey house. In order to use the calculator correctly and calculate the cost of building a house as accurately as possible, you need to carefully read about the house construction technologies that are used in our construction company.

Calculating the cost of a house using our calculator is not at all a difficult task, but nevertheless requires a careful approach. To correctly calculate the cost of building a house and analyze the calculation results, read this advice:

- the algorithm contains a square building model, without verandas and balconies;

- the estimated ceiling height in the model is 2.75 meters;

- the house construction calculator takes into account the total area of all rooms in the house, including the boiler room, bathrooms, stairs, and not just the living area;

- correctly determine the distance from the object to the Moscow bypass;

- The cost of construction is calculated using a calculator using current prices for building materials;

- Many factors influence the final result, so it should be taken into account that the result will be indicative; For accurate estimates, contact your company's specialists.

You can print the calculation results or send them to your email address.

If the cost of the house obtained on the calculator suits you, you should come to our office and discuss in detail all the details of construction with our designer. Then we can calculate the cost of building a house and evaluate it.

Construction technology

Arrangement of the base

If the price obtained as a result of calculations suits you and you have purchased everything you need, you can start working. We begin construction with the installation of a permanent foundation.

The easiest way to build a columnar foundation is:

- We mark the site for future construction.

- At corners and at the intersection points of walls, as well as on purlins more than 1.5 - 2 m wide, we dig recesses for support pillars.

- At the same stage, we dig and arrange a pit for draining water. We install a pipe in the pit, which we lay to the septic tank, cesspool or sewer.

- At the bottom of each recess we form a concrete pad up to 20 cm thick.

Installed foundation blocks

- We either install concrete blocks on the footing layer or lay bricks, forming vertical supports.

- On top of each support we lay several layers of roofing material, which will ensure waterproofing of the wood.

Laying crowns

The instructions for constructing the log house itself are not complicated, but some nuances are still worth considering:

- We begin work by laying the first crown. We make it from thicker timber (optimally 200x200 mm), impregnated with antiseptics and connected at the corners in half a tree. To attach the crown to the base, we use steel anchors with a diameter of 10-12 mm.

Covering crown made of timber impregnated with bitumen mastic

- We attach logs to the frame crown, on which we lay the floor. In the future, we will need to insulate the lower floor, so we can construct a rough flooring in advance, on cranial blocks attached to the joists.

- We lay the next crowns by combining the locks of the profile beam. For fastening we use birch dowels, which we hammer into pre-drilled holes.

Connecting parts with dowels

- To prevent the walls of the bathhouse from being blown through, we place jute strips between the crowns, which we place in special grooves.

- It is best to cut beam joints “in a warm corner” - this way the heat loss of the structure will be minimal.

“Warm corner” with additional jute sealing

Having brought the log house to the required height, we arrange the roof. To do this, we attach the rafters to the top trim, on which we place the sheathing.

It is best to use metal tiles or euro slate as a roofing material. If you want to completely preserve the style of the bathhouse, then wood chips, shingles or shingles are suitable.

Finishing and equipment

After the log house has stood and the shrinkage of the wood has been completed (this takes about a year when using timber with natural moisture and several months when building from chamber-dried blanks), you can begin finishing:

- We treat all wooden surfaces with a moisture-proofing compound intended for impregnation of wood in baths and saunas.

- We install high-quality windows and doors, carefully sealing the junctions with the walls to protect against drafts and heat loss.

- We lay communications - water supply system pipes, drain pipes, electrical wiring.

- Floors, walls, ceilings and roofs must be insulated from the inside using heat-resistant materials (basalt wool and analogues). We place a vapor barrier layer on top of the insulation, which will protect the thermal insulation from getting wet.

Heat and vapor barrier materials on floors and walls

- We cover the walls and ceilings with clapboards and lay the finished floor.

- We install or make a brick stove to heat the bathhouse and heat the water.

- In the steam room we install shelves made of wooden slats.

After that, all we have to do is install the furniture in the dressing room - and we can start steaming!

In small steam rooms, the stove must be reliably protected

Methods for calculating the amount of timber

In order to correctly calculate the required amount of timber needed for the construction of bathhouse walls, you can use several methods, each of which, unfortunately, will only give an approximate result that cannot take into account the quality of the lumber.

If a batch contains poor quality timber, it will either have to be replaced or used for other household needs. The calculations do not take into account openings, both doors and windows. After the calculation, you should add the volume of timber that will go to the floor and ceiling beams, to the racks or frame on the veranda.

If the walls inside the bathhouse have the same thickness, then they are counted together with the exterior ones; if the partitions are covered with timber of a smaller cross-section, then we count it separately. After the final calculation, we add another 10 - 15% to the final amount - this will be a more accurate figure that will reflect the real need for timber.

We count and get cubes

We find the total length of the timber wall, multiply it by the height of the wall and multiply the resulting figure by the thickness of the wall. For example, the length of the load-bearing wall according to the design of a bathhouse made of 6x6 m timber with a warm veranda is 34 m. The height of the wall is 3 m, we will build the bathhouse from 150 mm (0.15) timber. Multiply, we get 15.3 cubic meters

We count and get things

As in the first option, we find the length of the load-bearing walls - 34 meters and divide it by the length of the beam, which is always 6 meters. We get a figure indicating the number of pieces of timber that goes into laying 1 crown of a bathhouse 34 /6 = 5.67 pieces. The height of the walls is 3 meters, which means there are 20 crowns of 150x150 timber. 20x5.67=113.4 pcs. timber.

Peculiarities

Wood is an ideal option for building a bathhouse, since it is in this design that you can create ideal conditions of temperature and humidity, the effect of a Russian steam room.

There are several more reasons that make wooden beams a favorite among other materials:

- Wood has low thermal conductivity. The correct choice of the cross-section of a wooden beam allows you to heat the room in the shortest possible time, while it will take a long time to cool down. For northern latitudes, do not use timber with a cross-section below 200 mm; for central Russia, a section of 150 x 150 will be sufficient, and for the southern districts you can build from timber with dimensions of 100 x 100.

- To make timber, coniferous trees are often used, which have anti-allergenic and antibacterial effects.

- A small one-story bathhouse made of timber does not require a massive foundation, as, for example, for a brick or stone building.

- The timber shrinks several times less than a log. It is also not subject to warping, deformation, or cracking.

- It is quite convenient to work with timber, in contrast to rounded logs. Wooden buildings require virtually no interior finishing.

- The timber is usually already treated with biological and fire-resistant impregnations, which means that a building made from such raw materials will not rot, will not be eaten by insects, and the risk of fire is minimal.

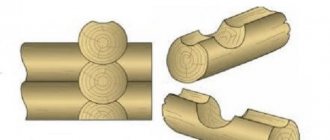

Advantages of buildings made of rounded logs

Rounded logs are a good alternative to sanded logs or sawn timber. They are not only not inferior to these types of building materials in terms of quality and durability, but also have a number of undeniable advantages:

- Z.

and due to the even and smooth surface of the log, the new house does not require decorative finishing.

- B.

rhubarbs have neat grooves made on special machines, thanks to which during construction they can be tightly joined at the corners of the structure.

- U.

The installation and construction time of a house can be significantly accelerated by calculating and preparing a complete building constructor in advance.

- D.

Houses made from rounded logs have an attractive appearance and can be built in different architectural styles - from the “European” version to the traditional Russian hut.

In the hands of a skilled craftsman, wood seems to acquire a soul and delights home owners with a pleasant shine, aroma and unique design. Cottages made from rounded logs can provide comfort; they are easier to breathe in compared to the stone frames of city apartments, and the ability of wood to accumulate heat in summer and retain it in winter makes it possible to build such buildings in areas with any type of climate.

The following is a complete list of calculations performed with a brief description of each item. If you haven't found the answer to your question, you can contact us via feedback.

[my_custom_ad_shortcode2]

What is a rounded log?

The material for rounded logs is usually coniferous wood. In terms of the ratio of cost and consumer qualities, pine is considered the best. When rounding, the top layer (sapwood) is cut off and the core remains, impregnated with resin and having a characteristic pine aroma.

By removing the sapwood on the log, the number of cracks decreases, which significantly increases the thermal insulation of the material. After rolling on end-cutting machines, the wood is impregnated with special mixtures that provide protection from the external environment. Despite multi-stage processing, the surface of the wood retains its magnificent pattern, which gives the appearance of the structure variety and elegance.

[my_custom_ad_shortcode1]

The simplest calculation is carried out using the formula = P*R2*N, where

P = 3.14; R2 is the radius of the rounded log squared; H is the length of the rounded log.

We multiply the result obtained by the number of logs needed to build a house or bathhouse. Do not forget to add 7%, which is allocated for the shrinkage of the log house. To facilitate the calculation, the results for different log diameters are presented in a table of log cubic capacity.

[my_custom_ad_shortcode4]