Vodyanoye

The classic solution in log houses is radiators, in which liquid heated to 40-95 ℃ (water, antifreeze, antifreeze) circulates.

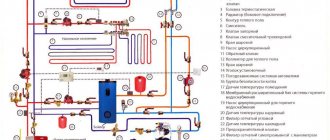

The coolant liquid moves in a closed loop through pipes from the boiler (gas, electric, solid fuel) to the radiators and back. There are two ways to circulate fluid:

- Forced. An electric circulation pump provides the required pressure in the pipes.

- Natural. It works due to the physical laws of gravity and hydrostatic pressure (i.e., the difference in height, as well as the difference in the density of the heated and cooled coolant).

Peculiarities

Forced circulation:

- Suitable for any heating area.

- Depends on power supply.

- More difficult to install.

Natural circulation:

- Does not depend on power supply.

- Used in small houses up to 50-100 m2.

Recommended heating equipment

When installing water heating, which is most popular in the CIS countries, several types of energy sources are used. Each type of boiler has certain advantages and disadvantages, so equipment should be selected taking into account the characteristics of the heated room and the availability of a particular fuel.

Electric boilers

Electric models are considered the easiest to use. They do not require large installation space and do not require complex maintenance. They are distinguished by stable and long-term operation.

The main disadvantage is high energy consumption.

Diesel heating

It has the highest efficiency in comparison with other types of boilers (about 95%). At the same time, it has a number of disadvantages. During operation, it spreads an unpleasant odor into the room. Only those rooms that are located away from living rooms are suitable for installing the boiler. In addition, a place to store fuel is required.

Diesel heating is not a budget option.

Solid fuel boilers

This type of equipment runs on wood, coal and briquettes. It is used mainly in non-gasified settlements. The efficiency of a boiler equipped with a heat accumulator is about 65%.

The main disadvantage is the need to constantly load fuel. When installing solid fuel boilers, it is necessary to take care of ventilation and storage space for fuel.

Gas boilers

The most popular type of heating boilers. Gas heating is the least expensive and does not require manual loading of material. The main disadvantage is considered to be a high fire hazard, therefore, when installing such boilers, all installation rules must be followed.

Gas boilers are divided into 2 types:

- Single-circuit - intended only for heating. It is small in size and weight, equipped with a closed combustion chamber and electronic ignition. The supply of hot water for domestic purposes is not provided in such boilers.

- Double-circuit with a boiler - capable of both heating the house and providing residents with hot water. Easy to use, easy to install and economical in fuel consumption. It operates almost silently and has a built-in security system.

Electrical

The most common electric heating systems are with electric convectors. Electric convector radiators are equipped with various heating elements - open filaments, heating elements, nichrome spirals.

- Models with filaments are cheap, but require good ventilation. Dust falls on the threads and burns, hence the unpleasant odors.

- A heating element (thread in a tube) is the safest option.

- Nichrome coils are chemically inert, durable, and highly efficient.

Modern electric radiators have a built-in programmer - a programmable thermostat. You can set a timer and set the desired temperature. And even set up work on specific days of the week, so as not to heat an empty house and warm the rooms before the owners arrive.

Peculiarities

- Mobile compact equipment.

- Comfortable use.

- Electricity costs.

- Energy dependence.

Features of heating houses made of timber

When choosing what kind of heating should be used in a wooden house made of timber, you need to take into account a number of factors.

Depending on the period of residence, wooden housing construction is divided into 2 types:

- seasonal;

- permanent.

Country houses used for living only in the warm season do not require constant heating. They need additional heating at night in early spring or late autumn. Installation of a heating system in this case is impractical. Local heating is used with heaters, convectors, fireplaces, and heat guns.

The heating of a wooden house made of timber, intended for permanent residence, must be installed in such a way that in any frost, a comfortable temperature is maintained inside the entire room.

In modern wooden houses, all communications are usually laid, so the power of the equipment and the layout of the heating system devices must be taken into account when designing the building. The following data is used as a basis:

- average and minimum temperatures in winter;

- air humidity, main direction and average wind speed in winter;

- total area of the room;

- layout;

- number of floors;

- building height;

- ceiling height;

- heat loss through walls, doors, windows, roof and floor.

It is important! Wood is a highly flammable material. When choosing heating for a house made of timber, first of all, pay attention to the safety of the system.

Next they calculate:

- costs for the purchase of equipment, consumables, fittings;

- cost of installation, commissioning and annual maintenance;

- accessibility during repair work and the ability to quickly troubleshoot problems;

- possibility of expansion in case of increasing living space;

- room heating speed;

- ease of heating control (switching on and off, temperature regulation, presence of an automatic control system);

- the efficiency of the selected system (the amount and cost of energy resources spent on maintaining a comfortable temperature in the house).

Based on the data obtained, conclusions are drawn about the profitability and feasibility of using the selected heating system.

Type of timber

It is also necessary to consider what type of timber the house is made of. Not only the calculation of heat loss and energy consumption for heating a log house, but also the specifics of installing the heating system depends on this.

Non-profiled (four-edged) solid beam

The easiest type of timber to manufacture. To obtain it, the edges of a log with natural moisture are cut off on four sides. Material thickness - 100-220 mm. It is mainly sold unpolished, which requires additional processing or finishing to give the structure an aesthetic appearance from the outside and inside.

Heating of a wooden house made of non-profiled solid timber must be carried out in several stages in order to avoid uneven shrinkage of individual elements. At this time, the house shrinks, which lasts from 6 to 12 months. Failure to follow the heating method leads to the formation of large cracks in the material and gaps between the beams as a result of their deformation.

Solid profiled timber

This type of timber is made according to specified dimensions with an accuracy of up to 1 mm, the side surfaces are ground. A lock (tenons and grooves) is cut out on the seats, which greatly facilitates installation and prevents the beams from moving to the side. The seams do not need to be caulked; a thin inter-crown insulation is sufficient.

Sold dry and with natural moisture (needs gradual drying, like non-profiled).

It is important! Ready-made house kits sold by companies must be equipped only with dry profiled timber.

Glued laminated timber

High-precision equipment is used for production. Lamels (boards) of coniferous trees (spruce, pine, larch, cedar) are treated with fire retardants and antiseptics. After mandatory drying, the workpieces are glued together under pressure.

To reduce internal stress when humidity and ambient temperature change, the direction of the fibers of adjacent lamellas is changed. The thickness of the material is controlled by the number of lamellas (from 2 to 7). Glued laminated timber of the required shape is turned from the resulting blank.

This is interesting! Heating in a house made of laminated veneer lumber, assembled from different species (outside - larch, inside - pine), is more efficient and economical.

Thermobeam

It is a composite beam of two lamellas with an insert of extruded polyurethane foam. This design has low thermal conductivity and light weight. This allows you to save on the foundation and further heating of the building.

It is important! Unscrupulous manufacturers of thermal timber, in order to save money, fill the space between the lamellas with materials not intended for this purpose. As a result, over time the insulation cakes, and the heat-saving qualities are sharply reduced.

| Type of timber | Advantages | Flaws |

| Non-profiled solid |

|

|

| Profiled solid |

|

|

| Profiled glued |

|

|

| Thermobeam |

|

|

The GOOD WOOD company, which has been implementing similar projects since 2005, will help you build a modern, eco-friendly house from timber on a turnkey basis.

Warm floor

The "warm floor" system can be water or electric. In the first case, the coolant moves in a closed loop - in tubes laid under the hearth screed. In the second, the tubes are replaced with electric heating cables.

Peculiarities

- Complicated installation.

- Expensive repairs (you have to remove the floors to the base).

- Does not affect the design of the room, but slightly reduces its height.

- Heats the entire area of the room evenly.

- There are no drafts or dry air.

- Convenient controls.

- Electricity costs (for underfloor heating with electric heating).

Types of heating systems

Currently, there are five heating schemes applicable for installation in a private two-story building.

These varieties include:

- Natural coolant circulation;

- Single-pipe engineering;

- Two-pipe analogue;

- Beam option;

- Full heating.

Method of organizing carrier movement

The operating principle of heating systems installed in the floor is no different from manifold systems. However, the heating elements in this case are pipeline circuits, rigidly fixed in a screed or hidden in the interfloor ceiling. In the construction market, the name “warm floors” has been assigned to such systems.

According to the method of organizing water movement, heating systems are divided into two types:

- Gravitational.

- Forced.

When using the gravitational principle, the heated medium, which weighs less than cold water, rushes upward along the contour due to gravity. As a result, a rather slow but sufficient circulation occurs.

As for collectors and heated floors, in such structures gravity is not able to start circulation due to insufficiently sharp angles of inclination of the pipes and limited diameters.

Gas boilers

If it is possible to connect to a gas pipeline, a gas boiler in a wooden house will be a good option. There are three types of boilers:

- atmospheric (a distinctive feature is a constant combustion mode, but when heated to a certain level, the gas supply automatically stops);

- turbine (in many ways similar to atmospheric, the difference is the presence of an air mass control system);

- condensation (has a more complex structure, in it the condensate located on the surface of the combustion chamber is first heated, which subsequently heats the coolant).

Gas boilers

Condensing boilers from Germany are characterized by high energy efficiency; they have decent efficiency. The only reason to refuse such equipment is the need to install heating in a wooden house without gas.

Calculation of the number of sections

It is not necessary to look for the most expensive heating devices to make the room comfortable. The main thing is to correctly calculate the number of sections. If the rooms are standard, then this greatly simplifies the calculations.

Often they resort to calculations based on the volume of space because they are simple, but at the same time give fairly accurate results.

- 1 m³ requires 41 W of power. If good double-glazed windows are installed and heat loss is minimal, then the indicator drops to 34 W.

- Room volume (m³) = area (m²) × height (m).

- Required heating power for the entire room (W) = room volume (m³) × 41 W (or 34 W).

- In the technical data sheets of devices, manufacturers indicate the heat transfer of one section.

- The total power (the value calculated in point 3) must be divided by the heat transfer of one section. The resulting number is the number of sections.

For example, the required thermal power is 2890 W, and the heat output of one section is 170 W. Then for this room you need to purchase 17 sections.

In a non-standard room, calculations are made using a more complex formulaSource rmnt.mirtesen.ru

If the room is non-standard, the calculations become more complicated. To calculate the total power, the features of double-glazed windows (double or triple), thermal insulation parameters of the walls, the ratio of the sizes of windows and floors, ceiling heights and other parameters are taken into account. Designers calculate all this using specialized software.

What can you save on?

When purchasing equipment and installing a heating system, the issue of saving invariably arises. Correct calculations of power will allow you to spend less money, while in terms of comfort you will not lose anything. For example, there are several options for installing a gas boiler in a wooden house. The heat exchange pattern and overall efficiency depend on its location.

The efficiency of the system depends on how good the heating radiators are, which ones are best to use in a particular situation, calculations will show. These elements may have different designs. A massive element will not be highly efficient if you need to heat a small room. Radiators according to the type of material used are divided into the following types:

- aluminum (they can be cast or obtained as a result of processing a workpiece);

- panel steel (ease of installation, efficiency of use);

- cast iron products (they take a long time to heat up, but can be used for more than half a century);

- tubular steel;

- modern bimetallic structures.

If gasification is present, you should first consider options using gas for heating. Options may vary in cost; you can always choose the best option for a particular case. It is possible to install a stove under a gas boiler, which will make your life more comfortable.

The need to connect a circulation pump

The single-pipe engineering circuit can be installed under the flooring without much difficulty. The only point that should not be overlooked by fans of inexpensive solutions is the fact that simply orienting the pipe horizontally or vertically will not be enough.

The fact is that the gravity configuration will work in a one-story building, but in a two-story building it will be useless. To put it into operation, you will have to acquire a special pump and provide for its installation at the design stage.

To prevent the pump from creating any inconvenience, it can be covered with noise insulation and installed away from the bedrooms and kitchen.

Basic rules for operation after construction

The first thing that needs to be done after construction is completed within the next couple of months is to paint the house. Paint will not only improve the exterior of the object, but will also provide reliable protection for the wood from external influences.

Despite the fact that laminated veneer lumber undergoes special impregnation and treatment at the manufacturing stage, paint and varnish coating of the external structural elements of the house is mandatory.

Further operation of the house is limited to compliance with the following rules:

- inside the house it is necessary to constantly maintain a stable temperature in the range of 20-22C;

- maintaining an optimal humidity level inside the house of 45-65%;

- residential buildings in cold weather need constant heating (the temperature inside the house should not fall below +5 degrees Celsius);

- Carry out regular ventilation and airing inside the residential building.

As for the manufacturability of a new house, one important rule needs to be learned here - routine maintenance work on laminated timber buildings during the shrinkage period is carried out at least 2 times a year.

Combination of engineering solutions

These approaches to organizing heating can be combined and complementary if necessary. As a result, a high-performance and inexpensive heating system for a two-story house will be assembled.

In order to accurately assess the strengths and weaknesses of each of the listed varieties, you should study them in detail.