Sanding timber inside a house is a mandatory operation that is performed after the construction and complete shrinkage of a wooden structure. The main purpose of this work is to level the surface, remove darkened and blue-damaged areas of wood and prepare the interior walls of a house or bathhouse for further painting or varnishing. Sanding is required not only for newly built wooden houses, but also for old timber buildings. Sanding allows you to remove a layer of old paint and refresh the color of the interior walls of your home. Which tool is suitable for the job and how to properly sand a timber and log house from the inside are questions that will be discussed in detail in this article.

Tools for grinding timber

The question of what is the best way to sand timber inside a house is far from idle.

The speed and quality of work largely depends on the correct choice of grinding devices. Previously, sanding was carried out only by hand using a chisel and sandpaper of different grits. But manual sanding is a rather long and tedious process. Today, manual grinding is practiced only for processing hard-to-reach places in the corners of logs, and grinding the entire area, as a rule, is done with different power tools.

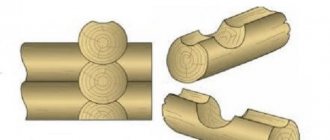

- The most common method of grinding beams is using an angle grinder or grinder with attachments in the form of grinding wheels of different numbers. For initial processing and surface cleaning, nozzles with coarse abrasive No. 30-60 are used. Fine sanding of the wooden surface is carried out using an abrasive attachment with fine grain No. 80-120. An angle grinder is also suitable for processing the internal walls of a log house made of planed logs.

- A belt sanding machine, which processes the surface using a rotating abrasive belt, does an excellent job of sanding a house made of profiled timber. The machine is well suited for removing old paintwork from a large area. The functionality of the device largely depends on the length of the working blade. It is better to process a large area with a machine designed for a belt length of 610 mm. Most models are equipped with a bag to collect shavings and sawdust, which allows for dust-free sanding.

- To sand the interior walls of a log house, you can use an orbital sander with a rectangular base. Machines of this type are distinguished by high quality grinding, so they are most often used for fine finishing and polishing of wooden walls. Models with a triangular platform are suitable for processing hard-to-reach areas - corners and grooves of a log house.

During sanding, a large amount of dust is generated. If wood processing is carried out with tools without a dust collector, then it is necessary to take care of body and respiratory protection: a respirator, goggles, gloves.

Rules for grinding timber

Sanding the walls of a wooden house with your own hands can only be done after the timber has dried.

This rule is especially important when the house is built from planed or profiled timber with natural moisture. If you start sanding ahead of schedule, you will not be able to completely remove the lint. After treatment with antiseptics, it will rise again and the process will have to be repeated. Some home craftsmen, having read incorrect information on the Internet, try to sand wood with water. However, wet wood should not be sanded as it will scuff. After such grinding it is unlikely that you will get a beautiful and smooth surface. It is best to start sanding from the upper floors of the house, so that a minimum of dust enters the finished rooms. It is not recommended to carry out work over the entire area at once. It is more convenient to sand in parts. The surface of the wall to be treated is divided into sections, which are sanded alternately.

Before sanding a wooden ceiling, in order to clearly see all the surface irregularities, it is necessary to install the correct lighting. The light should fall from one side with a slight angle of inclination. Large area ceilings are faster and more convenient to process using an orbital grinder. For ceilings with complex structures, it is better to use an eccentric sander.

When sanding with a grinder, wood often ignites. This usually happens if inexperienced craftsmen take on the job and select the wrong disk rotation speed. As a result, the tool operates at high speeds, and when pressed hard, a spark is formed, which ultimately leads to burning of the wood.

To avoid burning the timber during grinding, it is necessary to work at low speeds and not press hard on the tool. Another reason for wood fires is untimely change of sanding wheels. Worn or chip-clogged tips can cause a spark. During work, it is necessary to ensure that the cables are laid correctly, which, if twisted or broken, can also cause a fire.

Other useful tips

It is worth starting sanding work only when the roof is erected. After all, additional load on the base of the building will inevitably lead to the formation of new irregularities, and minor defects of a different kind will appear.

Sometimes the timber turns blue. In this case, you do not need to start sanding until the walls have been cleaned with sandpaper. Only after this can they be polished.

Darkening of the beams is often observed approximately 6-7 days after their treatment. It was necessary to coat them with a protective compound first.

An important point. It is not recommended to grind fresh timber material, because then the attachments quickly become clogged. So it’s worth using a plastic abrasive disc. But you need to take into account that the tree in this case must be collected precisely during the cold period.

Timber grinding technology

Sanding the walls of a log house is carried out in stages and includes three types of processing: rough, fine and finishing.

- At the first stage, rough processing of the timber is performed, the task of which is to remove all significant irregularities from the surface and prepare it for finer grinding. For this work, the abrasive with the largest grain size is selected. During initial processing, the nozzles very quickly become clogged with dust, and they have to be changed frequently.

- For basic sanding, fine-grain sandpaper is used. After processing, the result should be a flat and smooth surface, ready for subsequent painting.

- Final sanding is not always performed, but in cases where it is necessary to bring the surface into ideal condition for the subsequent application of a transparent varnish coating. The walls are polished using the finest abrasive to make the surface as smooth as possible.

To grind the grooves, use a grinder with an attachment several sizes smaller than the diameter of the circle. The corners are processed manually with a chisel with a working part width of 20 mm.

After each grinding stage, it is necessary to clean the surface from dust using a vacuum cleaner. After completing all grinding work, the surface must be treated with antiseptics that protect the wood from rot and mold. This must be done no later than seven days after sanding.

The nuances of such work

A wooden building can be assembled with exceptional quality. In this case, the design will certainly have minor defects that spoil the overall appearance. Individual rows of beams usually protrude by about 1-2 mm. The walls are not completely level, and this may not suit the owners.

The only way to ensure that the internal walls become perfectly smooth is by sanding the timber. It is also possible to obtain the following desired results.

Only incipient spots of black mold (other fungal growths) will be removed.

All minor damage to the timber that appeared during its laying can be eliminated.

The surface of the wood is covered with fibers. It is necessary to treat the material with antiseptic impregnations, and remove all these excesses.

Successful:

- highlight the texture of wood;

- give the drawing freshness;

- brighten the surface.

Various types of physical impacts, even after short-term use of the room, leave marks on the walls. Polishing helps remove a small layer of damaged wood, after which the walls become absolutely smooth.

Also, by grinding it, the no longer relevant antiseptic impregnation and the varnish coating that has lost its attractiveness are removed from the surface. The timber regains its original wood color - natural, fresh.

Typical mistakes when sanding timber

Many home craftsmen, when performing grinding on their own, often make mistakes, among which the most common are:

- Grinding wet timber, which inevitably leads to re-processing;

- Incorrect choice of tool, which affects the quality of grinding;

- Working at high speeds, which contributes to the appearance of depressions and grooves on the surface;

- Sanded walls remain without a protective coating for a long time, which causes darkening of the wood.

Sanding is a complex and time-consuming job that requires a lot of patience and a competent approach. It’s not easy to do it yourself, without certain skills and experience.

Basic mistakes

If a person sands walls for the first time, he may make certain mistakes, as a result of which the quality of the work is significantly reduced:

- The work is carried out at maximum tool speeds, which often leads to the formation of deep grooves.

- If there are resin residues on the surface, then during sanding it is smeared on the wall, which significantly complicates the further process.

- If there are defects in the radial wood, that is, its peeling, then first the surface must be treated with glue, allowed to dry, and only then proceed to sanding.

- If water-based paint or varnish is used, then after the first painting the pile may rise and therefore it is necessary to re-sand.

- If paints and varnishes based on chemical solvents are used, then in such cases the pile usually does not rise.

- It is recommended to carry out the specified work in a new house after installing the roof, but before installing doors, windows, ceilings and floors.

- Please note that over time the wood hardens and it will be more difficult to sand.

- Often, to speed up work, inexperienced craftsmen use large and powerful grinders or grinders, but they quickly tire the hand, and therefore damage the surface.

Professional grinding services

Our specialists are highly qualified, have extensive experience and proven work skills. All this ensures high quality grinding, which we will perform in accordance with the deadlines specified in the contract. In our work, we use modern professional power tools that allow us to achieve a perfectly smooth and even surface. If you need high-quality sanding of a country cottage, country house or bathhouse, we are very willing to carry out work of any level of complexity. Contacting us is very simple - on the “Contacts” page you will find all the coordinates of our company, and you can also leave your request.

Calculate the cost of painting and insulating your home right now