If you still consider plywood to be a rough building material, then it’s time to discard these prejudices. Cost-effectiveness, durability, versatility are just a small part of the reasons why it is increasingly appearing in interiors as an independent unit. This article contains a step-by-step guide with photos on how to make plywood shelves with your own hands. And 6 models that everyone will like.

Preparing your desktop

First of all, you need to prepare your table on which you will work. There should be no unnecessary things on it and every tool should be at hand. Not everyone has their own desktop and has probably already thought about creating one. Making a table is not difficult, but choosing a place for it in the house is difficult. The ideal option is an insulated balcony, on which you can do crafts at any time. I have already written about preparing the table in a separate article and tried to describe in as much detail as possible the entire process of creating it. If you don’t know how to prepare your workplace, then read the following Article. After you have completed the process of creating a table, try to start choosing your future craft.

Functionality of shelves

There are many small items that cannot be put in a drawer or closet in every home. I want the necessary little things to always be at hand; shelves are used for this purpose.

You can decorate the wall or floor space in an original way using a shelf. Place a designer vase or books, figurines or victory cups, a collection of objects or photographs.

You can use the shelf in the bathroom, children's room, kitchen, bedroom, living room, and in each room it will fulfill its role.

We choose quality material

The main material is plywood. The choice is always difficult. Each of us has probably encountered such a problem as delamination of plywood from the end part and asked the question, what causes this delamination? Well, of course, this is mainly due to low-quality plywood. If this is not the first time you have picked up a jigsaw, then you can select plywood from the remnants of a previous craft. If you are new to sawing and you don’t have plywood, then buy it at a hardware store. Choosing material for sawing is always difficult. You should always choose plywood carefully, often look at the defects of the wood (knots, cracks) and draw conclusions. The difficulty in choosing plywood lies in the fact that no matter how you guess at its defects and shelf life. For example, you bought plywood, cleaned it, translated the drawing and suddenly it began to delaminate. Of course, this has happened to almost everyone and it’s oh, how unpleasant. So it is better to pay attention when choosing and choose good plywood. I wrote a special Article in which all the principles of choosing plywood are described step by step.

Features of the material

First, let's figure out why plywood? The answer is simple: characteristics that make pressed veneer an excellent alternative to wood, MDF or chipboard.

- Flexibility due to its small thickness, lightness and strength.

- Resistant to temperature changes.

- Simple installation - you can cut, glue and install this material without special skills.

- Cost-effective - the cost of a plywood sheet is significantly lower than that of natural wood.

Instagram @lot1design

Instagram @studiojessejames

Instagram @jayne.s.davies

The main disadvantage of the material is that it is not suitable for areas with high humidity. Since the material is made from specially prepared veneer, which is glued together, when exposed to water, harmful fumes from the glue may be released.

But for living rooms or corridors this material is perfect. Therefore, if you want to quickly and inexpensively furnish your home, read our tips on how to make a shelf out of plywood with your own hands.

- Furniture

How to make a box under the bed with your own hands

Stripping plywood

We clean our plywood with sandpaper. As you already know, “Medium-grained” and “Fine-grained” sandpaper is used for cleaning plywood when sawing. You've probably seen sandpaper in hardware stores, and that's what we'll need. In your work you will need “Coarse-grained”, “Medium-grained” and “Fine-grained” sandpaper. Each of them has its own property, but a completely different coating, by which it is classified. “Coarse-grained” sandpaper is used for processing rough plywood, i.e. which has many defects, chips, and cracks. “Medium-grained” sandpaper is used for processing plywood after “Coarse” sandpaper and has a slight coating. “Fine-grained” or otherwise “Nulevka”. This sandpaper serves as the final process for stripping plywood. It gives the plywood smoothness, and therefore the plywood will be pleasant to the touch. Sand the prepared plywood in stages, starting with medium-grain sandpaper and ending with fine sandpaper. Sanding should be done along the layers, not across. A well-polished surface should be flat, completely smooth, glossy in the light and silky to the touch. How best to prepare plywood for sawing and which sandpaper is best to choose Read here. After stripping, check the plywood for burrs and small irregularities. If there are no visible defects, then you can proceed to the process of translating the drawing.

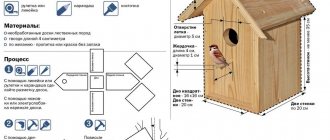

Step-by-step instructions for assembling the shelf

- Marking. The entire course of further work and, accordingly, the result depend on the correct and accurate marking of the material. Draw a drawing of the shelf, accurately indicating all its dimensions. When marking, take into account the thickness of the board. Use a tape measure or ruler to transfer all measurements onto the boards. Before starting work, the boards must be placed on a flat surface.

- Manufacturing of shelf parts. Using a jigsaw or hacksaw, carefully cut the boards to the desired size. The board cuts must be even. Clean the cut area with sandpaper. Sanding parts is an important element of the job. Sand the boards well using sanding paper or a sander. Cover the boards with stain and varnish or paint.

- Assembly of parts. On the top and bottom pieces of the shelf, mark lines with a pencil to attach the sides of the shelf. Using self-tapping screws, connect the shelf parts. If the shelf consists of several compartments, connect the entire structure in series.

- Shelf fastening. Brackets must be attached to the ends of the shelf so that the shelf can be hung on the wall. If the shelf is long enough, then it is necessary to evenly distribute the brackets along the entire length of the shelf for reliability. Hang the brackets on dowels, which must be placed horizontally on the wall, using a building level for this. Otherwise, the shelf will not be level, which will cause objects to fall. To give the shelf originality, you can use decorative brackets.

If desired, you can make open and closed shelves, with or without a back wall. You can make several shelves and place them on the wall in a certain order: in a ladder, in a checkerboard pattern, along the perimeter of the wall, or in another way.

When making floor shelves, depending on the purpose, it is necessary to consider their attachment to the wall for stability.

Corner shelves

Corner shelves fit well into the interior of any room, making empty corners functional. Most often, such shelves are used in the kitchen or bathroom, where there is little space and you want to use all the free space as much as possible.

When making a corner shelf, it is necessary to take into account the angle of the wall of the room where the shelf will be located.

For a corner shelf, glue the two sides of the shelf together to form a corner and let the glue dry well. Can be secured using self-tapping screws or dowels into specially made grooves. Then, using brackets, they are attached to the two walls of the corner, placing the dowels horizontally in level.

Exclusive shelves

Tree branches can be used as side walls. Horizontal and vertical tree cuts can be used as shelves.

When making shelves with several tiers, you can use rope as side walls, which will give the shelf originality. You can cut an openwork shelf from plywood, which will give it lightness and originality.

Translation of the drawing

For me, drawing translation has always been the main process in my work. I will tell you a couple of rules, as well as tips for high-quality translation of a drawing. Many people transfer the drawing onto plywood not only using a pencil and copying, but also using “Black Tape”, glue the drawing to the plywood, then wash off the drawing with water and the markings of the drawing remain on the plywood. In general, there are many ways, but I will tell you about the most common method. To transfer the drawing onto prepared plywood, you must use a copy, a ruler, a sharp pencil and a non-writing pen. Fasten the drawing in plywood using buttons or simply hold it with your left hand. Check if the drawing fits the dimensions. Arrange the clock drawing so that you can use a sheet of plywood as economically as possible. Translate the drawing using a non-writing pen and ruler. There is no need to rush, because your future craft depends on the drawing.

Types of shelves

- Standard or classic rectangular shelves that are attached to the wall and come in various sizes.

- Corner shelves fit well into the corner of the room, decorating it. Such shelves are attached to two walls.

- Floor shelves can stand on the floor or be attached to the wall, depending on the purpose of their use.

- Exclusive shelves using non-standard materials, for example, tree branches, ropes.

To decorate a room or premises, you first need to decide which shelf you want to see in your home. The shelf can be made with a closed back wall or made completely closed using glass doors.

Drilling holes in the parts

As you have already noticed, the parts contain parts of the grooves that need to be cut out from the inside. To cut out such parts, you need to drill holes in them using a hand drill or, as in the old fashioned way, make holes with an awl. By the way, the diameter of the hole must be at least 1 mm, otherwise you can damage the elements of the drawing, which, alas, are sometimes difficult to restore. To avoid damaging your work table when drilling holes, you must place a board under the workpiece so as not to damage the work table. It is always difficult to drill holes alone, so ask a friend to help you in your task.

Operation of shelves

- Distribute items evenly on the shelf so as not to overload one side.

- Wipe the shelves with a damp cloth, as the wood may become warped.

- Calculate the weight of the items on the shelf and the fastening of the structure.

Making shelves with your own hands is not only about diversifying the interior of your home with original things, it is also an interesting process that can develop into a hobby or allow you to provide yourself with additional income.

You can give this shelf to friends and relatives. The convenience of a self-made shelf also lies in the fact that you can always repaint it to match the color of the interior, change the shape and design.

Sawing parts

There are many rules for cutting, but you need to stick to the most common ones. First of all, you need to cut out the internal parts, only then according to the external pattern. There is no need to rush when cutting. The main thing is to always keep the jigsaw straight at a 90-degree angle when cutting. Cut out the parts along the lines you accurately marked. The movements of the jigsaw should always be smooth up and down. Also, do not forget to monitor your posture. Try to avoid bevels and unevenness. If you go off the line while cutting, don't worry. Such bevels and irregularities can be removed using flat files or “coarse-grained” sandpaper.

Cleaning Parts

You should always clean the parts of a future craft carefully. At the very beginning of the work, you already sanded the plywood with sandpaper. Now you have to do a small part of stripping the plywood. Using medium-grain sandpaper, sand the edges of the parts and the back of the plywood. “Fine-grained” sandpaper is considered the final stage of cleaning parts. It is better to clean the front part of the parts with fine sandpaper. When processing plywood, take your time. You can also use a rounded file, which is convenient for cleaning the inside of the holes. Try to ensure that the parts come out without burrs or irregularities.

Material for work

Before starting work, be sure to check the quality of the material. The boards must be smooth, without knots, cracks, dry and without traces of mold. Before work, treat them with an antiseptic primer.

If you use tree branches for a shelf, then sand the trunk well so that during the work there are no surprises in the form of a rotten knot or traces of mold under the bark. You can also use chipboard and laminated chipboard for work.

Varnishing crafts

If desired, you can transform our craft by covering it with Wood Varnish, preferably colorless. Read how best to varnish a craft. Try to choose a quality varnish. Varnishing is carried out using a special brush “For glue”. Take your time. Try not to leave visible marks or scratches on the craft.