Forests have always played a prominent role in the life of the peoples of Russia, constituting one of the foundations of material well-being. And today, one of the oldest industries in the country, the forestry industry, regularly supplies lumber and products made from wood to the market.

Structure of the timber industry complex

During its development, the forestry industry has absorbed four areas of activity:

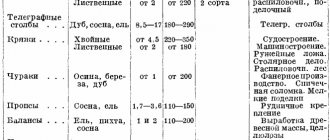

- Deforestation and development of wood according to standard assortments.

- Woodworking is a series of technological processes of mechanical and chemical properties, intended for the production of lumber and finished products in the form of furniture and building materials.

- Paper and pulp production producing:

- paper,

- cardboard,

- roofing materials,

- varnishes,

- wood fiber and particle boards,

- cellulose.

It is based on the chemical processing of wood.

- Forest chemicals offering consumers:

- charcoal,

- tannins,

- rosin,

- acids,

- polysaccharides,

- turpentine.

Furniture manufacturing

This sub-industry is characterized by high competition. Furniture production enterprises compete not only with well-known foreign brands, but also with shadow manufacturers. Because of this, the furniture market has not formed and is of an evaluative nature.

About 6 thousand manufacturers of various ranks are involved in the furniture industry. Products of the sub-industry are produced in 7 federal districts and 79 constituent entities. Large and medium-sized enterprises employ 6% of workers, producing 80% of the total volume of furniture in the country.

Leaders in furniture production:

- The Central Federal District produces 36.7% of furniture products;

- Volga Federal District – 30.7%;

- Northwestern Federal District – 9.2%;

- Siberian district – 7.8%.

Structure of furniture production in the Russian Federation:

- cabinet household furniture – 28%;

- soft – 20%

- kitchen – 16%

- office – 11%;

- mattresses – 9%;

- children's – 7%

- for sitting – 6%;

- other – 3%.

In 2022, furniture worth $294.1 million was exported from Russia.

Raw materials resources of Russia

Our country has a quarter of the world's forest reserves, covering almost half of its territory. The area of exploitable forests in Russia is estimated at 156 million hectares.

Timber industry complex

The largest forest reserves are concentrated in the European north, Siberia, and the Far East. There are very few resources north and south of the central forest zone, which have been subject to very intensive development in the past. The southern regions are noteworthy in this regard, with the exception of the mountainous regions of the Caucasus, where the level of tree vegetation has fallen below the natural background. Steppes and tundra, due to their natural characteristics, have practically no forests.

Currently, intensive logging activities are carried out in the following areas:

- Amur, Arkhangelsk, Irkutsk, Kirov, Kostroma, Perm, Tomsk regions;

- Krasnoyarsk and Khabarovsk territories;

- in the Komi Republic.

Branches of the forest industry and factors of their location

Logging

In the past, seasonal work intended for cutting down trees for firewood and logs has now become a major industry, equipped with high-performance mobile equipment and qualified personnel. Today the logging industry includes:

- Chopping.

- Cutting, accompanied by the collection of associated raw materials and materials (resin and tar).

- River rafting.

- Transshipment of products from one type of transport to another.

- Use of low-grade wood and production waste.

At the end of 2022, wood production in the country as a whole amounted to:

- 127.8 million m3 – business (industrial);

- 13.3 million m3 – wood (fuel).

This is one and a half times less than the peak figures of the 80s of the last century. Today, the area of forests that can be cut down annually without causing natural damage is 550 million m3. A simple calculation shows that at best only 25-30% of Russian forest potential is used.

Logging industry

The domestic logging industry has reached this level only by consistently increasing production volumes over the past 20 years in the regions:

- North of the European part. It is here that a significant number of logging roads are concentrated, there are a number of rafting rivers, and the large seaports of Arkhangelsk and Murmansk are located. In addition, the region is located relatively close to the most developed regions of Russia and European countries.

- East Siberian region. The southern part of the Irkutsk region and Krasnoyarsk Territory uses: the Yenisei for rafting timber to the Igarsk port for export, and the Trans-Siberian Railway for transporting it to the European part of the country.

- Ural. One of the largest economic centers harvests about 20% of Russian timber, using it for its own needs and transporting it to other areas.

- Far East. Possessing significant reserves of both mature (the age of the species is 80-100 years) and overmature forests (more than 100 years); and being in close proximity to the economically promising countries of the Asia-Pacific region, the region has great opportunities to increase industry volume.

From the above analysis of the location of the main logging facilities, it is clear that the decisive factors for their location are the availability of a raw material base and a developed transport infrastructure.

Woodworking

One of the most labor-intensive industries of the forestry complex, products that are widely used. Using mechanical and chemical processing of wood, the industry produces:

- beams and slabs;

- materials and finished products for construction: plywood, boards, parquet, doors, frames;

- rough blanks and finished products for all types of transport;

- furniture;

- wooden cases and cases for products and tools;

- container;

- devices used in the textile industry;

- matches.

Woodworking technological processes are quite complex and multi-stage, which requires a high level of professional training and the availability of a large amount of equipment. Manufactured in the form of material cutting devices (sawmills and sawmills); drying chambers; processing machines; equipment for applying varnishes, enamels, paints; as well as a number of special-purpose and auxiliary installations. At the same time, the finished products themselves can be: mass, serial (large, small and medium), individual and exclusive production.

Wood industry

The decisive factors for the location of industry enterprises are:

- Providing energy resources and water.

- Availability of transport intersections (places of transshipment from one type of transport to another) and developed infrastructure.

- Sufficiency of qualified labor resources.

- Proximity to areas where finished products are consumed.

Pulp and paper

Currently, about 200 pulp and paper industry enterprises operate in Russia. The final products of their production are:

- Cellulose, which is the most valuable raw material for the light and food industries, perfumes and cosmetics, aircraft manufacturing and electronics.

- Paper for stationery, technical, household, sanitary and household purposes.

- Cardboard.

- Viscose.

- Process by-products in the form of: lignosulfonate, tall oil and furfural.

- Thermal insulation.

Technological processes in the pulp and paper industry are very expensive in terms of raw materials, electricity and water. Which, of course, affects the location of the relevant industries.

Pulp and paper

Wood processing industry in the world

Not all countries in the world are able to provide themselves with raw materials for the development of the wood processing industry. In this case, they import wood and manufacture various types of products from it.

Finland, which has significant forest reserves, uses its own resources to produce lumber. This production does not require large financial expenditures, and the end result is a high-quality product that can be used for various purposes. Finland exports most of its products to the UK and Japan.

Timber products produced in Finland have the following characteristics:

- Low cost of raw materials, which attracts most countries;

- Good quality wood;

- Possibility of further wood processing;

- The first readiness of a natural resource for use;

- No production waste.

In other countries, the focus is on the production of furniture, up to the production of completely finished structures. Such production already requires significant investments, which quickly pay off after the successful sale of the finished product.

Most of the production in other countries is furniture production, since it does not include primary wood processing. The manufacturer buys the processed material on the domestic or foreign market and produces its products.

Unlike many countries in the world, in Russia there is a full production cycle, which begins with wood extraction and ends with processing and production of finished products. In both the United States and the Russian Federation, the production of wood products is very well developed, but in terms of territory size it is inferior to Russia.

China has good forest areas, but the country's government is not able to establish full-fledged wood processing activities due to natural factors. Germany prefers to buy wood to preserve the integrity of its own forests. It cooperates mainly with Finland.

Development of the timber and wood processing industry

Russia, which is the world leader in timber reserves, is significantly inferior to its competitors in the production of timber products: the USA, Canada, Sweden, Finland, China, and Brazil. Annually harvesting 0.5 billion tons of forest biomass, our country manages to use only a quarter of it.

A significant part of substandard materials: branches, twigs, bark, pine needles is simply thrown away. More than half of exports are poorly processed raw materials. We are second to New Zealand in supplying round timber to the world market (14% of the world market volume) (16% of the volume).

It is clear that in these conditions, the domestic timber industry has enormous development prospects, allowing it to bring billions of dollars of profit to the state budget. A favorable factor for success in this much-needed business is the intensive development of China, which is focused on imported products in the industry. While our country's own needs are fully satisfied by the forestry industry.

The main reasons for hindering the development of the forestry and wood processing industries are:

- Extensive methods of using this type of biological resources, implying the cutting of wild trees.

- The lack of a sufficiently clear and demanding forest management policy, which leads to numerous fires, unauthorized logging, diseases and death of forests.

- Insufficient capital investment, causing physical wear and tear of equipment with its subsequent purchase abroad. This indicates an insufficient level of production of woodworking machines and mechanisms. The same factor forces manufacturers to limit themselves to an extremely low level of wood processing, generating low productivity and a high percentage of waste.

- Unattractiveness of investments.

However, despite all the difficulties, the industry has shown steady growth in logging over the past two decades. Which, together with the priority state policy reflected in the long-term development strategy, allows us to count on the successful solution of existing problems.

World development trends

Depending on the places of concentration of forests on our planet, the following zones are distinguished:

- Northern. This is the territory of taiga forests on the Eurasian and North American continents, where coniferous timber is harvested. A number of developed countries of the Eurasian and North American continents (USA, Russia, Finland, Canada, Sweden) specialize in the supply of wood raw materials on an international scale.

- Southern. Hardwood timber is harvested in three main regions of the globe - the forests of Brazil, tropical Africa and southeast Asia. Huge reserves of wood raw materials are concentrated on the South American continent, from where it is exported to Europe and Japan for further processing, or used as fuel for heating homes. In countries located in the southern hemisphere, alternative raw materials (not wood) are widely used for the production of paper products: bamboo branches are processed in India, sisal in Brazil and Tanzania, jute in Bangladesh, and sugar cane pulp in Peru.

The uneven distribution of forest resources, which are classified as renewable, poses the threat of their excessive use, which can lead to total deforestation of territories. For example, uncontrolled deforestation of equatorial rainforests has already led to large-scale environmental problems in Brazil and Mexico.

The developing countries of Asia, Africa and South America are increasing the procurement of wood raw materials every year, and China and India have already appeared among the traditional developed countries (USA, Canada, Finland, etc.), which were previously among the top ten procurement countries , Brazil and Indonesia, Nigeria and Congo. However, in developed countries, the percentage of industrial (high-quality) wood exceeds the share of firewood (used for fuel) several times, and in the countries of Latin America and Asia this picture is completely opposite. In the USA, Sweden, Finland, Canada, etc. In the structure of fuel consumption, firewood takes up from 3 to 12%, while in African countries - up to 78%, in China - up to 65%, in South America, about 57% of all harvested wood raw materials is used for firewood.