Wood shrinkage is a physical phenomenon that causes a decrease in the overall dimensions and total volume of wood in the process of removing moisture. This metamorphosis is directly related to the microscopic structure of the tree and requires special attention when working with it.

Indicators related to changes in humidity significantly affect the structural and technical values of the strength characteristics, density and ductility of wood. Therefore, when harvesting, storing and processing timber, it is important to consider whether wood shrinkage will occur under existing environmental conditions.

What you need to know about wood drying

Wood has a pronounced anisotropic structure. This means that properties manifest themselves differently in different directions. All the cells that make up a tree differ in size in transverse and longitudinal sections. Microfibrils located in the cell membrane are located along the axis of the cell, and moisture occupies the space between them. For this reason, when moisture is removed, the transverse dimensions in the radial and tangential directions change significantly. It is worth canceling that in the tangential direction, that is, when cutting along the fibers tangentially to the growth rings, the shrinkage of wood is 1.5-2 times higher.

Types of wood shrinkage

Depending on the number of water molecules removed, wood shrinkage is considered as:

- Full. It appears when the entire amount of moisture from the structural fibers of the wood has completely evaporated. At the same time, its humidity decreases from the upper values of the hygroscopicity limit to zero. In this case, the hygroscopic limit is usually understood as the maximum moisture content of the material.

- Volumetric. It manifests itself in a decrease in the volume of wood due to the evaporation of interconnected water particles.

Determination of the nature and type of shrinkage usually occurs in laboratory conditions. A sample of material is placed in water until completely saturated. Then the dimensions are measured using special tools - a micrometer or caliper. After this, the samples are dried until completely dry in an oven, and their linear dimensions are measured again.

These tests are necessary in determining the indicator characterizing the degree of expansion and contraction of wood fibers under physical influence.

Summing up the results

Thus, we can assume that wood shrinkage is an inevitable process. Almost all types of wood are susceptible to this phenomenon, which can have both negative and positive qualities.

Natural drying takes a long time. If you build a house from raw wood, then it will be impossible for a person to live in it until the drying process is completed. This may take quite a lot of time.

In some cases, the duration of natural shrinkage is about a year. Of course, nowadays people purchase material for construction that has been subjected to artificial shrinkage. This saves time. When purchasing such material, you should definitely pay attention to its quality.

You should never skimp on building materials. This can have a detrimental effect on the structure being built. This is especially true for wood. If it is of high quality, the structure can last for several decades. At the same time, it will retain its original appearance.

If during the construction process wood was used that was not dried according to technology, there is a high probability that the house will soon begin to collapse. High-quality wood should not have any defects. In this case, distortion of the form is also not allowed.

Shrinkage and swelling coefficients

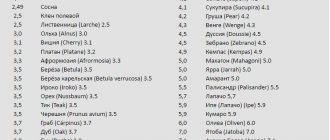

The amount of shrinkage of lumber as a percentage decreases in humidity is determined by the shrinkage coefficient. It characterizes the degree of transformation of the overall dimensions of the wooden sample under study when the amount of moisture decreases by 1%. Information and methods for finding this coefficient can be found by studying GOST 6782.2-75.

GOST 6782.2-75 Lumber products from deciduous wood. Shrinkage amount

1 file 715.91 KB

Swelling of wood occurs as a result of saturation of the fibers with moisture. This occurs at elevated humidity levels. This process, the reverse of wood shrinkage, causes an increase in the linear dimensions of the timber. In numerical equivalent, this phenomenon is expressed by finding the swelling coefficient. The method for determining this indicator is described in GOST 16483.35-88.

The degree of shrinkage and swelling for each type of wood is individual. This is due to the peculiarities of the microscopic structure and chemical composition of wood fibers. Representatives of coniferous species have vertical and horizontal resin passages in their fiber structure. This significantly distinguishes them from hardwoods, the structure of which is represented by developed conductive vessels.

GOST 16483.35-88 Wood. Method for determining swelling

1 file 160.00 KB

All tree species have different shrinkage coefficients and, depending on its value, are formed into groups:

- shrinkage in volume does not reach 0.40% - weeping spruce, Caucasian fir, poplar, common ash.

- shrinkage from 0.40% to 0.47% - European or forest beech, elm, oak, cordate linden, alder;

- shrinkage is manifested by more than 0.47% - birch, European larch, Norway maple.

The value of the shrinkage coefficient helps to predict the likelihood of internal stresses and cracking as a result of uneven evaporation of moisture and take measures to prevent their occurrence.

Ecology DIRECTORY

Swelling is a mandatory stage in most technological processes in chemical wood technology. This phenomenon is specific to high-molecular compounds and always precedes their dissolution. It manifests itself in an increase in the volume of the polymer as a result of the diffusion of solvent molecules into its thickness and should be considered as the dissolution of a low molecular weight liquid in the polymer.[...]

Wood consists of high-molecular compounds such as cellulose, lignin, polysaccharides, etc. The dissolution process of polymeric materials can be divided into two stages - swelling and dissolution. The rate of swelling depends on the ability of solvent molecules to penetrate into the intermolecular space, which is decisive in the dissolution process. [...]

| Swelling of the cell wall of spruce wood during sulfite cooking [3] |

The absorption of moisture by wood up to a moisture content of 23% is accompanied by swelling, i.e., an increase in the linear and volumetric dimensions of the wood. Wood swells and shrinks, most in the tangential direction and less in the longitudinal direction.[...]

Severe shrinkage or excessive swelling of the wood after gluing can significantly weaken the strength of the adhesive joint. To equalize the humidity, the workpieces are kept indoors for 1-2 days until gluing. [...]

To isolate putative lignin-carbohydrate complexes from wood, many researchers first subjected it to vigorous grinding. The most interesting research in this area is. Bjorkman [17], who subjected dry wood to vigorous grinding in toluene, i.e., in an environment that prevented its swelling. [...]

In Fig. Figure 15 shows the swelling of the fibers of spring and summer Weymouth pine wood when swelling in trimethylbenzylammonium hydroxide.[...]

Extensive research has been carried out for many years in the field of the structure of wood and its components by Odintsov and Erinsh [321-323] using the methods of sorption of vapors and gases, where the role of the processes of swelling and separation of these components in their final submicroscopic capillary structure is clarified.[...]

When regenerating rubber using the water-neutral method, continuous stirring promotes better swelling in softeners. In addition, when softwood resins are used as softeners, the water-soluble acids they contain destroy textile fiber residues (a similar effect is achieved by adding zinc and calcium chlorides). All this has a positive effect on the quality of the regenerate.[...]

After planing, even with a double plane, the surface does not yet become completely smooth, suitable for painting. When drying, wood fibers form pile. Villi, almost invisible to the eye, make the surface rough. In addition, in the process of preparing for painting, it is repeatedly moistened, and due to the heterogeneous structure of the wood, some of its cells absorb more moisture, others less. Therefore, the swelling and drying of the fibers also occur unevenly over the entire surface - and pile again forms and roughness appears. Pile is formed after processes such as puttying, wet grinding with pumice or other powders, gluing the ends, priming, even waxing, because all these compositions contain various liquids. [...]

During sulfite cooking, due to the sulfitation of lignin and the hydrolysis of the weakest LU bonds, the ability of wood matter to swell increases many times (Fig. 6.2). Swelling of wood, one of the most important stages of the cooking process, occurs already when the temperature rises and stands at 100 C. [...]

There are many known methods of grafting with cuttings. All of them can be combined into two groups. The first group includes methods of grafting under bark, when a scion cutting is inserted under the bark peeled off from the wood of the rootstock. These vaccinations can be carried out during the period of active spring cambium activity, from. swelling of the buds and the beginning of spring sap flow before the start of intensive shoot growth (approximately 10-15 days after the end of flowering of the apple tree). Another group includes methods in which similar tissues of the cutting and rootstock are combined - bark, cambium, wood (copulation, cleft, cleft, etc.). These vaccinations can begin at the end of winter, when the danger of night frosts below 15°C has passed, and continue ■ until intensive shoot growth begins.[...]

In the southern regions, pruning begins in the second half of February, in the northern regions - in early March, when the danger of severe frosts has passed, at a temperature not lower than -2., -4″ C; at a lower temperature, the wood becomes brittle, even cuts are not obtained, and a lot of overgrown wood breaks off. It is best to finish pruning before the buds swell, otherwise the beginning movement of nutrients will bring growth substances closer to the ends of the branches, which will be removed during pruning. It is difficult to carry out pruning during the spring thaw, so it is better to start it early in order to finish it by the time the soil completely thaws. [...]

Carboxymethylcellulose and hydrolytic lignin can be used as fillers for urea resins. The viscosity is significantly increased (5-10 times) by adding 0.5-1.0% carboxymethylcellulose to the resin. For better swelling of carboxymethylcellulose, it is recommended to add it to the resin 8-15 hours before using the glue. Hydrolytic lignin is introduced in an amount of 3-5% by weight of the resin. The introduction of fillers not only prevents the glue from penetrating into the pores of the wood, but also increases the elasticity of the cured adhesive layer. However, excess filler reduces the resin content in the adhesive layer and its strength.[...]

Mass concentration. With increasing mass concentration, the thickness of the fibrous layer between the knives increases and therefore a relatively smaller number of fibers are exposed to the cutting action of the knives. In this case, due to an increase in interfiber friction forces, the degree of swelling and fibrillation of the fibers increases. Therefore, grinding a mass of high concentration is especially advisable when grinding cellulose from deciduous wood and annual plants.[...]

This operation was carried out on lignified sections, previously freed from lignin using sodium chlorite in an acetic acid medium. The sections were then treated with p-phenylase; benzoyl chloride for the purpose of esterification of polysaccharides. The sections, brightly colored orange-red, were photometered after swelling in pyridine. By subjecting sections consisting of holocellulose to such treatment before and after removal of hemicelluloses, it was possible to establish that the bulk of hemicelluloses in spruce and birch wood are concentrated in the outer layers of the secondary wall. Thus, when extracting a cut of spruce holocellulose with 16% sodium hydroxide, it was found that up to 60-80% of the total amount of polysaccharides was extracted from the outer layers of the cell, about 50% from the middle of the cell wall, and from the layer B3 only 16%. . A similar picture was observed for cross sections of libriform from birch wood.[...]

Intensification of the dissolution process can be achieved by accelerating the diffusion of solvent molecules into the intermolecular space. The acceleration of the dissolution processes of many polymer materials under the influence of acoustic vibrations is based precisely on the intensification of swelling processes. Consequently, acoustic exposure must certainly facilitate the penetration of protective agents into the fibrous, porous structure of wood. This is confirmed by the results of studies of various centrifugal pulsation devices used in many processes in the pulp and paper industry [173-175].[...]

Cuttings are harvested at the beginning of winter, before the onset of severe frosts, since frozen cuttings do not take root well. For this purpose, healthy, well-fruiting mother trees of various varieties are isolated. For grafting, annual growths from the peripheral and illuminated parts of the crown with well-ripened wood up to 30-50 cm long and 6-10 mm thick are used. Before grafting, cuttings are stored in cold basements in sand at a temperature of 0-2°C or in snow piles. When making snow, it is necessary to take measures to prevent damage to cuttings by mouse-like rodents. In exceptional cases, spring harvesting of cuttings is also allowed, carried out before the buds begin to swell, if the winter was mild and no traces of freezing were detected. [...]

Increasing the temperature of alkaline extraction also promotes the decomposition of polysaccharides into terminal reducing groups. Therefore, extraction with aqueous alkalis is recommended to be carried out at room or low temperature and in an atmosphere of nitrogen or other inert gas. It is also known that preliminary swelling of plant tissue in liquid ammonia allows the release of hemicelluloses at lower alkali concentrations [29]. This method was first proposed by Yang and Parves [30]. They used it to isolate xylans from maple and aspen wood [31]. Recently it has been used by a number of researchers.[...]

The term “chemically modified cellulose” indicates that the cellulose, under the influence of acids or oxidizing agents, has undergone changes to such an extent that it leads to a decrease in mechanical strength, although it does not cause visible fiber destruction [1]. This term indicates that cellulose does not undergo changes in purely physical properties (for example, swelling in water), chemical properties leading to the formation of cellulose derivatives, such as acetates or nitrates, and there is no severe acid hydrolysis with the gradual formation of partially soluble non-fibrous mixtures of cellodextrin, crystalline oligosaccharides and, finally, glucose. Degradation to glucose, sometimes mixed with small quantities of other reducing sugars, has been carried out industrially under the name of the process of saccharification or hydrolysis of wood (Chapter XXI).[...]

Recently, a more advanced method for determining lignin with hydrofluoric acid was proposed [11]. The authors of this technique emphasize a number of advantages of hydrofluoric acid compared to sulfuric acid when used for the quantitative determination of lignin. Hydrofluoric acid has a very high penetrating ability, causes strong swelling of wood, dissolves and hydrolyzes carbohydrates well, without causing humification. For the quantitative determination of lignin, it was proposed to use less concentrated hydrofluoric acid instead of liquid NI. All equipment for determination (Fig. 38) must be made of fluoroplastic. The filter is also made of fluoroplastic and equipped with a bottom made of porous monel.[...]

Many studies have been devoted to studying the effect of ultrasound on cellulose fibers [447–459]. Some researchers have compared or combined the effects of ultrasound with various mechanical influences. Thus, Yaime, Kronert and Neuhaus [447] studied the effect of ultrasound on cellulose fibers in comparison with high-frequency mechanical vibrations and showed that ultrasound with a frequency of 20-3000 kHz loosens the fiber structure, increases the degree of its swelling and dehydration. The mechanical strength of paper made from such celluloses is increased, especially the tear strength. High-frequency mechanical vibrations act similarly. Iwasaki, Lindberg and Meyer [448] believe that the general pattern of changes in fiber structure under the influence of ultrasound in an aqueous environment is similar to changes in the structure of fibers during mechanical grinding. In this case, profound changes in the morphological structure of the fibers occur, leading to shifts in the secondary cell wall, separation of large pieces from the primary wall, then to swelling of the secondary wall and its defibrillation. In the work of Safonova and Klenkova [449, 450], when studying micrographs of fibers subjected to ultrasound in water, it was shown that there are other, deeper disturbances in the structure of the fiber, which becomes penetrated by a whole network of numerous transverse channels. It is noted [457] that early wood fibers and fibers that have not been dried are more susceptible to ultrasound. [...]

Preliminary experiments with delignified areas led Dadswell and Ellis [351] to the conclusion that between the cells there is a fiber-binding substance of neither pectic nor lignin nature, which can be removed using a hot weak (0.08 to 0.18%) aqueous solution of sodium hydroxide. In areas treated in this way, cell-by-cell separation was observed. Harlow [36] expressed the opinion that an alkali, even as weak as that just indicated, causes some swelling, and hence, to a certain extent, a mechanical cracking effect, since he believed that perhaps the intercellular substance is compressed during cell growth into such a thin layer that the primary walls, especially along tangential surfaces, can sometimes come into contact with each other. Such cohesion of the primary walls may explain the fact that in areas of fully delignified mature wood, cell by cell does not separate without any mechanical treatment. Further experiments by Wardrop and Dadswell [37] showed that this explanation is probably correct.[...]

The chemical composition of the fiber has a great influence on grinding: the content of a-cellulose, hemicelluloses (pentosans, hexosans, polyuronides) and lignin. On the contrary, fibers with a high content of hemicelluloses (for example, low-temperature sulfite pulp, bisulfite pulp, cellulose from hardwoods and annual plants) are less crystalline, swell well in water and therefore are easily ground. However, not all hemicelluloses have the same effect on grinding. Only those that are not “embedded” in the cellulose crystal lattice and are accessible to water adsorption have a positive effect, i.e. capable of swelling.[...]

Allowances for shrinkage

The susceptibility of timber to drying and swelling refers to properties that have a negative impact on the performance of the tree. In order to achieve the specified dimensions of the product after harvesting and sawing, an allowance is provided for the shrinkage of the material. This is a universal means of avoiding deformation of the wood during the process of drying it to the required humidity levels.

Numerical values of allowances for shrinkage of lumber are provided for in GOST 6782.1-75. The degrees of shrinkage of the most common wood species in GOST are indicated in the form of a table with data on the values of the nominal thickness and width of lumber in millimeters and the final moisture content as a percentage.

GOST 6782.1-75 Lumber products from coniferous wood. Shrinkage amount

1 file 423.34 KB

To calculate the allowance and find the actual dimensions of the product, you need to make a calculation according to the data from the table. For convenience and better understanding by the developers of the standard, examples of such calculations are given.

Proper drying of wood

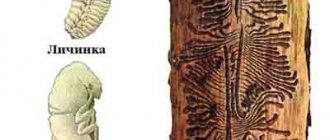

The process of wood shrinkage can be brought under control if you follow the rules for drying timber. The main task in this matter is to ensure uniform removal of moisture from the fibers that make up the structure of the tree. In industrial conditions, this is ensured in special electric or gas drying chambers. The most common type of drying under natural conditions is atmospheric drying. The harvested material is protected from precipitation, as well as the influence of negative environmental factors, using an insulating coating and is stored in several rows under intensive ventilation.

Wood is a durable, but capricious structural material. Its mechanical and physical properties depend on external factors. Significant temperature changes and non-compliance with humidity conditions lead to shrinkage or swelling of the wood. Uneven distribution of moisture along the wood fibers can lead to distortion of the linear dimensions of the timber. Therefore, in the process of working with wood, starting with the workpiece, it is important to take into account the likelihood of changes in the dimensions of the product and observe allowances for shrinkage.