When you start immersing yourself in making furniture with your own hands, there is a need to simplify your work with the same type of operations associated with the preliminary marking of parts for fasteners. Furniture drilling jigs are an excellent tool for the home craftsman. Many people prefer to make templates from blanks themselves. However, there are quite a few budget devices on sale on Aliexpress that are easier to buy than to reproduce. And they will last much longer, maintaining the original accurate calibration.

You can read about how to properly prepare sawn parts for further assembly in the article about adding and drilling chipboard with your own hands.

How to make templates with your own hands

The pattern is a flat part. Its dimensions are selected taking into account the difference in the radii of the cutter and the copy ring.

Ready drawings

There are many patterns posted on the Internet for different tasks and sizes of the copy sleeve. Most publications are provided with formulas into which you need to substitute the dimensions of your workpiece. All that remains is to calculate the dimensions of the template, draw it on graph paper and transfer it to sheet material.

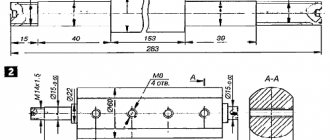

Drawing of a copy sleeve.

Examples of drawings are shown below.

What you need

Stencils are made from the following materials:

- tool steel (the most durable option);

- duralumin;

- plastics;

- plywood;

- plexiglass.

Sheet thickness – from 2 to 10 mm.

Tools needed:

- drill with a set of drills;

- jigsaw or hacksaw;

- file;

- grinding wheel.

To make stencils you need a drill with a set of drills.

Manufacturing process

Proceed in this order:

- Draw the outer contour of the groove on the sheet stock.

- Calculate the difference between the diameters of the cutter and bushing and divide it by 2.

- From the drawn outline, retreat a distance equal to the number obtained in step 2 and draw a parallel line.

- Cut out a template using it.

- File and sand the edges of the product.

A curved template is cut in this way: first, a series of small holes are drilled along the contour, then the material between them is removed with wire cutters or another suitable tool.

Universal furniture jig for drilling

In terms of functionality, it combines the two previous devices, since it can adapt to marking with drills of different diameters, and the ruler allows you to set any desired distance from the edge and pitch. It is used both for drilling the front surface of parts and the end.

Well-known manufacturers of furniture jigs include Cheron, Kreg and Wolfcraft. Before choosing any model, we recommend comparing prices, quality and functionality with smaller manufacturers and suppliers of furniture components Blum, Hettich and others. Often the optimal price-quality ratio, and even with a guarantee, can be found where it seems that “everything is expensive.” Do not exclude this possibility for yourself and consider all possible options. After all, a furniture jig can serve faithfully for many years, helping to speed up production processes without losing the quality and accuracy of making furniture with your own hands.

DIY accessories for a router

Most products can be made independently. The manufacturing procedure for the most popular ones is outlined below.

Tenoner

Proceed like this:

- On both sides of the plywood strip, install identical racks of blocks with notches in the middle.

- Attach router guides equipped with stops to them on the top, bottom and sides.

- Install a movable element on the plywood base to regulate the size of the edge of the part, equipped with a wing nut or other lock.

Tenoners are used to perform precise operations.

An alternative device is a conductor.

It consists of the following parts:

- grounds;

- stops;

- movable slide.

The product is used to perform small operations that require high precision.

Copy sleeve

The preferred material is tool steel. But in private workshops, due to the lack of professional metalworking equipment, bushings are most often made of simple steel or duralumin.

Procedure:

- Cut a circle from a metal plate with the same diameter as the hole in the router base.

- Take a piece of pipe with an internal cross-section 2–4 mm larger than the cutter and cut it off.

- Sand the bushing with oil sandpaper.

- In a metal circle, cut a hole in the middle with such a diameter that the sleeve fits tightly into it.

- Weld the flange to the sleeve or connect them by riveting the ends and pre-seating them with glue.

Another option is practiced, for which you need:

- steel or duralumin washer;

- plumbing extension cord;

- nut with the same thread as the extension.

The copying sleeve is made of tool steel.

They do this:

- Cut the nut to make a ring and grind it through.

- A circle is cut out of steel or aluminum 2 mm thick.

- The metal is removed along the edge on a sharpening machine.

- Place the circle on the base of the router.

- Place the tool vertically.

- Markings for fastenings are applied through the holes in the sole.

- Drill holes with a thin drill, then enlarge them with a tool of the required diameter.

- Put on the washer and screw in the nut.

- Holding the workpiece in a vice, gradually remove the thread with a grinder so that it is flush with the nut.

- The product is trimmed.

- Align the bushing on the grinding wheel and attach it to the router base.

Guides for working with a router

The simplest homemade guide looks like a rail attached to the workpiece with clamps. You can fix several parts at once and make a groove in them in 1 pass.

A more complex option is a structure made from a board and a sheet of plywood that serves as a base. With this design, it is easier to accurately fix the guide on the cutting line.

If milling cutters of different sizes are needed to process the workpiece, use the option with a folding bar. It is attached to the board base using door hinges.

Types of stencils

Let's look at what a stencil is. This is a device that helps to apply a pattern or identical symbols to a surface. For example, templates for carving wooden trims occupy a special place in this niche, since they are produced specifically so that the master can perform complex work intended to decorate the interior of the house and external walls.

Stencils for carving wood with a jigsaw exist for the following interior items:

- ribbon carved ornament;

- carved platbands;

- pilaster;

- towels;

- brackets;

- carved balusters, etc.

Stencil with a complex pattern for carving

These are specialized templates, it is from them that three-dimensional ornaments and patterns are created. They greatly facilitate the task of changing the appearance of the interior. After all, you don’t have to look for a stencil, but you can simply download it or order it through the World Wide Web. And then create your masterpiece.