Today, frame house construction is very popular not only abroad, but also in Russia. This is primarily due to the speed of construction of residential buildings and affordable cost. But the arrangement of such buildings has a number of peculiarities. The ceiling in a frame house deserves special attention. Its design differs significantly from ceilings in reinforced concrete and brick buildings.

Design features of frame buildings

As a rule, frame house-building technology for the construction of residential buildings involves the use mainly of lumber. The exception is the foundation.

To equip the building frame and its cladding, ready-made structural parts manufactured in the factory are used. This allows you to significantly speed up the process of assembling a building on a construction site.

Houses using this technology are quite light, do not shrink, and do not require the construction of heavy, powerful foundations. Immediately after assembling the frame and its cladding, you can begin finishing the façade and interior decoration of the residential premises. In this case, you can use almost any material offered on the modern construction market.

How to independently increase the lifespan of your home

Today's frame construction technologies are different. Builders use frame-frame structures that do not require significant repairs. They only need to be updated, then you can live in such a prefabricated house for 50 years. To protect your frame house, before installing the structure, you need to treat the timber from excess moisture. Insects are another factor that reduces the strength of the frame. It is necessary to carry out timely treatment of the entire surface of the house, because the service life of the frame house directly depends on proper care. With proper maintenance of life, a frame house can last more than 100 years, so that children, grandchildren, and possibly great-grandchildren of the first owner can live in it.

One of the main mistakes is the construction of such a dwelling without design documentation checked or drawn up by a specialist. This is something you definitely shouldn’t skimp on. This is exactly what significantly affects the service life of a frame house. Only a well-developed project, optimally selected material taking into account the characteristics of the area, will help such a house last as long as possible.

Despite the fact that frame-block technology is distinguished by its efficiency, it is also not worth saving too much. Russian craftsmen sin by replacing load-bearing structures and shields with cheaper materials, which is strictly not allowed. A geological conclusion, which is often simply ignored for the sake of economy, will not be superfluous. However, no one is safe from quicksand on their site; in this case, you will simply have to abandon construction on the chosen site in order to avoid the loss of the built house. Only compliance with all factors will allow you to build a durable frame house.

The modernity is such that a contracting organization, having one project, offers it to developers many times. These are the so-called “turnkey houses”. Despite their apparent simplicity and convenience, they may not last long.

The importance of the ceiling

Ceilings in frame houses are not only a decorative component of the room. They simultaneously act as a thermal barrier, regardless of location (between the room and the attic or between the rooms of the first and second floors of the building). Therefore, the heat loss rate of a residential building will also depend on the arrangement of the ceiling base.

When choosing the most suitable ceiling coverings in terms of performance characteristics, the aesthetic part of the surface should not suffer. The decoration of the living space should be in the same style. The ceiling decoration here plays the same important role as the finishing coating of the walls. When selecting materials for ceiling cladding, it is necessary to take into account the purpose and other nuances of a particular room.

Why do houses last less in Russia than in Canada and Finland?

Frame houses in Russia, despite positive reviews from residents, have a service life two times less than in Canada or America. Why does this happen if the construction technology, in fact, should not be different? Let's consider the reasons for reducing the service life of a frame building.

A high-quality frame house should last at least 50 years

- Approach to choosing wood and timber. No one in Canada will ever use natural moisture timber in the construction of a frame house. It would never even occur to anyone to save money on this. And with us it’s quite natural. Only laminated veneer lumber, which does not dry out, does not absorb excess moisture, does not change its shape and is not deformed.

- In Russia, the construction of frame houses is carried out either by special companies or by the owners themselves. Both of them want to save money, since frame buildings are positioned in our country as economy-class buildings. By the way, abroad, a modern frame-panel house belongs to the category of elite housing, since the environmental friendliness and naturalness of the source material are valued there. Therefore, there is no point in saving abroad, and a frame house is built only from the most modern materials, be it insulation or waterproofing.

- A huge amount of preparatory work is being carried out in developed countries. This includes additional insulation of the leeward side, and study of precipitation in a specific area, and calculation of the roof angle based on average annual precipitation in the form of snow. In our country, at best, a soil test will be carried out to determine the type of foundation. And even then not always.

As a result, we get what appears to be a frame house, but it was not built using technologies that were developed in Finland or America. We have a surrogate panel house with a reduced service life, which only vaguely resembles modern Finnish and Canadian “frameworks”.

Comparison of construction times for houses made of different materials

Ceiling partitions

In wooden frame buildings, block ceiling partitions are used. In this case, the beams must be of a certain cross-section and mounted with a specified spacing.

When constructing a one-story building with an attic, the recommended cross-section of floor beams is 50x100 mm. For two-story and three-story structures, thicker and stronger beams must be used. Moreover, their installation is carried out in smaller increments, i.e. there should be more of them in number.

Most often, for residential buildings built using frame technology, the following ceiling design options are used:

- Tensioners;

- Hanging;

- Hemmed.

The ceiling height in frame houses is relatively small - no more than 260 cm. For this reason, most owners of such buildings prefer suspended ceiling structures. This allows you to significantly save room space.

If according to a typical construction project there are no ceiling height restrictions, then many people prefer hanging options.

Removing condensate

To get rid of this factor, you will need to install natural or forced ventilation. Often, two ventilation grilles are installed at the edges of the surface, located diagonally. This will reduce the pressure drop and prevent the accumulation of condensate. Even before the installation is completed, immediately after the construction is completed, special compounds against mold and mildew are used. They are used to coat wooden surfaces.

If film ceilings are installed in rooms with a high moisture content: a bathroom or kitchen, then the steam will accumulate on the surface and will not penetrate into the base of the wood. This will eliminate the disadvantage of condensation accumulation.

Draining water from a suspended ceiling Source zen.yandex.ru

Roof leaks may also occur. In this case, you need to immediately call specialists who will unfasten the structure in one of the corners and remove the accumulated water. It will take some time to dry the surface, after which the product will be reattached.

Types of ceiling coverings

Today on the market there are many finishing materials specifically designed for finishing rough ceiling coverings. At the same time, when choosing a coating, it is necessary to take into account many different factors: the design features of the building, the functions of the room, the operational characteristics of the facing coating. And also the ceiling in a frame residential building must be in harmony with the overall interior of the room. Finishing options:

- Gypsum boards with subsequent painting;

- Tension fabric made of polyvinyl chloride;

- Metal or plastic panels.

Listed above are the most popular and affordable finishing materials on the construction market. But there are other solutions for how to finish the ceiling in a frame house.

Stretch ceiling

The PVC film is perfectly stretched, resulting in a perfectly flat, elastic surface. Textile fabrics are also often used in suspended ceiling structures.

Such structures are an ideal solution if the building is expected to shrink, as they are not afraid of deformation. Photo printing, various decorative patterns and drawings can be applied to the glossy surface of the PVC canvas, if this is included in the design project of the room.

Installation of such a ceiling does not require significant financial and time expenditures, but it is quite difficult to install it yourself.

Plasterboard coverings

Ceilings in frame houses are also finished with plasterboard slabs. They help hide any unevenness and flaws in the ceiling base and increase sound insulation characteristics.

This coating option does not require significant investment. After installation, the surface of the slabs can be painted in any color or covered with special wallpaper, or simply whitewashed.

Ceiling made of fiberboard and plywood

Plywood ceilings in frame houses are considered the cheapest option. This material is most often used as cladding for small country houses made using frame technology.

Of course, with the help of this building material it will not be possible to achieve a particularly decorative base, but for the technical rooms of a frame building this option is the most appropriate.

Panel ceilings

The main advantages of using suspended panel structures for arranging the ceiling are the affordable cost of the material and the ease of its installation.

Installation work can be done independently, even without the involvement of an assistant and having some experience in assembling such structures.

Panel ceilings are characterized by increased resistance to moisture, do not require special care during operation, and also have a fairly pleasant appearance.

There remains free space between such a covering and the main ceiling, which allows you to install an additional layer of thermal insulation or sound insulation, or to install lighting fixtures at the covering level. Also, such designs differ from others in their maintainability.

Nuances of preparatory work

Installing suspended ceilings in a house requires careful preparation. You will need to take into account the type of materials from which the walls were lined. If plasterboard or lining was used for finishing, then installation of the frame will not cause any special complications. But a surface based on a rounded beam can significantly complicate the work for a specialist.

Stretch ceiling in a house made of rounded logs Source bouw.ru

In some cases, the top floor is pre-insulated. This will reduce temperature changes that can affect the quality of the ceiling material. In hot weather, such a structure can sag, and in severe frost, it can crack. If there are leaks, the roof must be repaired.

Important! You will first need to check the quality of the installed wiring. If the cable becomes very hot or the wires are close to the structure, this may damage the fabric or cause a fire.

The type of construction is selected based on the ceiling height. The profile version does not matter much, but the plastic one is much more flexible and can be adjusted to the unevenness of the wall cladding. It is also worth considering that if the building was erected recently, it will take 2 years to wait for the foundation to shrink.

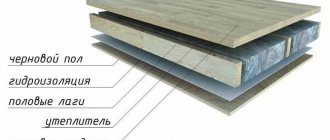

Insulation materials for ceilings

Any residential building must be equipped with a heating system for year-round and comfortable living. As a rule, this is quite an expensive pleasure. Therefore, to minimize the cost of fuel used (wood, gas or electricity) in a residential building, it is necessary to reduce heat losses even at the construction stage. For this purpose, special thermal insulation materials are used, which help reduce the rate of heat loss of the building, incl. frame structure by almost 30%.

Styrofoam

This material has been used in construction for quite some time as insulation. It is made on the basis of foamed polystyrene, consisting of air bubbles.

Advantages of insulation:

- Very light;

- Simplicity and speed of installation work;

- Long period of operation;

- High thermal insulation performance.

Ceilings in frame houses, insulated with foam boards, simultaneously solve the problem of sound insulation of rooms. But when choosing thermal insulation, it is necessary to take into account that this material is flammable and at high temperatures releases toxic substances into the environment.

Penoplex

This heat insulator is based on extruded polystyrene foam, which differs from the usual one in its higher density. It also consists of small air bubbles, but has improved thermal insulation qualities and high strength. The disadvantages are the same as those of polystyrene foam.

Mineral wool

This insulation has its own varieties: stone wool, slag wool, glass wool.

The structure of the material is made up of millions of small mineral threads that are placed in a chaotic manner.

There is rolled mineral insulation. It is softer and lighter. Manufacturers also produce such insulation in stronger and denser slabs (mats).

Ecowool

This is a loose thermal insulator made from waste paper, which is produced in different densities. 80% of the material consists of cellulose, the remaining 20% are special additives that give the insulation material the necessary performance characteristics.

Various antiseptics against harmful microorganisms, bacteria and fire retardants that promote self-extinguishing are used as such additives.

Expanded clay

The ceiling in a frame house is also finished with such a fairly ancient material as expanded clay.

The raw materials are obtained from preheated clay in specialized ovens, which rotate during operation. At a sufficiently high temperature, clay granules swell and melt. Then they are cooled and distributed according to size.

Polyurethane foam insulation

PPU (polyurethane foam insulation) is only gaining popularity in the modern construction market.

A layer of thermal insulation is sprayed directly onto the ceiling base. The insulation is a special two-component solution, which is supplied to the surface using special equipment through a gun under high pressure. These two components are in separate containers and are mixed only when they are simultaneously sprayed over the surface, forming a foam material as a result of a chemical reaction.

This technology of ceiling insulation makes it possible to obtain a continuous coating without voids, cracks, or connecting areas and to achieve sufficiently high thermal insulation characteristics.

Installation process

The procedure is not particularly complicated, but has a number of features depending on the type of decoration of the room. The procedure for assembling the ceiling is as follows:

- First, the room is measured and the materials are fastened using a profile.

- The product is connected to the base corner and beams, then a similar fastening is carried out for the opposite corner.

- The frame is being installed.

- Fixation is carried out in a baguette.

- The fabric is carefully stretched and fixed in the corners.

Differences in the installation procedure for wooden buildings

Wood is a rather complex material. In timber-based buildings, suspended ceilings are not installed so often. The work is complex and requires experience and certain skills from the specialist. During the installation procedure you will need to consider the following recommendations:

- It will be necessary to carry out ventilation, since the false ceiling will not allow the wood to breathe. Because of this, mold and mildew often appear.

- The work is carried out using a tension gun, but you need to be extremely careful to avoid a possible fire.

- Boards and joists will need to be lined several weeks in advance with special compounds that will prevent fire and rotting of the material.

- Before installation, you will need to carefully level the ceiling. The baguette will need to be cut at a certain angle. Then the joints are glued. To simplify installation, you can create a plank underlay. The wood drills well and holds well with self-tapping screws. There will be no need to waste time securing dowels.

- Fastening a beam with a baguette in the middle is not used, since the next fastener will be located at the junction of the logs, and this is contraindicated. When marking a little further, the width of the marking line will become slightly less than the middle. To carry out such procedures you will need the help of an experienced specialist.

Installation of stretch ceiling Source ngzt.ru

Working with the stove installed

You will need to protect the baguette and coating from high temperatures. The stove will not interfere with the installation of the ceiling under the following conditions:

- You will need to first build a box based on plasterboard.

- You will need to secure a mortgage.

The surface will need to be cleaned more often, but soot and smoke can be easily removed with most cleaning solutions. It is contraindicated to use abrasives and aggressive mixtures, acids, as this can lead to damage or deformation of the structure.

What requirements must be met?

The construction “pie” of the frame will be able to cope with the tasks assigned to it for many years only if the builders comply with the following rules and requirements for its installation:

- High load-bearing capacity of the structure, which must withstand severe loads without deformation or damage;

- Sufficient rigidity of the slabs;

- Excellent sound insulation properties;

- Fire resistance, fire safety;

- Optimal thermal conductivity - the design must protect living rooms from low temperatures in winter and high temperatures in summer.

- Light weight - excessive weight can destroy or damage foundations and load-bearing walls;

To install floors in “frameworks,” it is necessary to choose lightweight, high-quality materials with high performance characteristics.