Machine tools and tools in finished form are available in a wide range in specialized stores. However, their price is not affordable for everyone, especially a novice master. Homemade machines are a way out of a situation with a limited budget. Let's consider the features of their use and manufacture. Let's talk about the most popular devices. The information will help you decide on the choice of necessary equipment for organizing work in the workshop.

Using a non-factory electric grinder Source notperfect.ru

Using homemade machines in the workshop

The work that is performed in the workshop affects the equipment of the room with special devices. Typically, equipment is placed if the free area is at least 3 m2.

Workshops are often set up in small rooms, outbuildings, and garages. The best place is a separate building. In this case, the noise from the work being performed will not disturb other residents of the house.

Universal workshops are often set up to perform various jobs. If a person is engaged in the production of any products, then specific homemade tools and devices are made. Often workshops are equipped with machines for carpentry and processing of metal blanks. Often, premises for the repair of wheeled vehicles are also set up.

Basically the workshop is equipped with:

- devices that allow you to prepare tools, facilitate labor and mechanize operations;

- homemade products for processing metal parts;

- workbenches.

A workbench made of wooden elements Source skilljob.ru

It is also necessary to install shelves in the room where various tools will be stored. At the same time, they ensure unhindered access to them and compliance with fire safety rules.

How to make a handicraft at home?

The support for guiding the cutter along the shaft of the workpiece is a tool rest. It is best to make it from a steel pipe or angle iron, because wooden supports wear out quickly and are not able to withstand as heavy loads as a metal part of the same size.

You can make it by welding two pipes in a T-shape, or you can do it even simpler and fix a piece of board with a wooden boss on the frame, but the accuracy and wear resistance of such a design is not durable. The main thing in arranging a tool rest is that the upper edge of the pipe or angle must correspond to the axis of rotation of the workpiece: in this case, the risk of breaking the chisel is minimal.

Important!

When working on a lathe, only the lower part of the workpiece can be processed! Failure to do so may cause the incisor to become jammed or fractured, which can result in serious injury. When operating a woodworking machine, be sure to wear safety glasses to reduce the risk of injury.

Workbench for a carpenter

This type of equipment is a table. It is distinguished by its high strength and the presence of 2 vices on the tabletop. The table is also equipped with clamps that clamp the workpieces during planing. In addition, the workbench may still have places where other homemade devices, such as a router, will be attached.

A special table must have a comfortable height. She matches the height of the master. The minimum length of the workbench is 1000 mm. Often it is equal to 1700 mm or even 2000 mm. The standard width is 800 mm.

Before making a workbench for carpentry, get acquainted with its main parts Source infourok.ru

A workbench table is created as follows:

- The table surface is created - this is a shield, which is made from oak, beech or hornbeam boards with a minimum thickness of 55 mm. They are tightly fitted to each other. The boards used are impregnated with drying oil before joining. To create a rigid structure, a 50 mm block is used. It is fixed around the perimeter of the working surface.

- The supporting elements of the workbench are made. To do this, use linden or pine timber. Its size is 120*120 mm or 150*150 mm, and its length is approximately 1200 mm. The supports are connected by jumpers in the horizontal plane. To do this, take boards that are fixed at a distance of 300 mm from the floor.

- Make homemade devices to accommodate the tool. These are shelves located under the countertop. When they are open, they are often replaced with bedside tables.

- Attach a vice.

If a stationary workbench is created, its supporting elements are fixed to the floor. Depending on the specifics of the work being performed, mobile and collapsible tables are also manufactured.

Mobile workbench on wheels Source foamin.ru

Carpenter's workbench vice

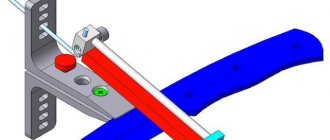

This homemade tool is made using a screw rod. Its thread length must be at least 160 mm. In this case, the diameter of the rod itself must be 20 mm. For the vice you will also need wooden blocks and metal pins. The manufacturing sequence is as follows:

- Prepare a block of 200*300 mm. Its minimum thickness should be 50 mm. This will be one of the sponges. A hole for a screw is drilled in the center of the workpiece. On the sides of it, two more holes are made for the studs.

- A second movable jaw 200*180 mm is cut out and similar holes are drilled in it.

- A threaded pin is inserted into the workpiece. A handle is installed at one end. To prevent the jaws from moving, pins with a cross section of 10 mm are passed through other holes.

Wooden vice for a carpenter Source infradom.ru

Properties of plywood

Plywood is a very versatile material. It is sufficiently durable, easy to use, widely available and relatively inexpensive. That is why plywood is often used not only to make furniture or decorative items with your own hands, but also to make homemade machines.

Physical and mechanical characteristics and standard sizes of construction plywood of the FSF and FBS grades

Some machine parts can be perfectly replaced with parts made from plywood. For example, a plywood table is perfectly used for cutting material; casings and movable supports made of plywood have also proven themselves to be excellent in use. And these are not all the parts that can be made from plywood in order to make a machine with your own hands.

- When choosing a material, you should take into account the load the plywood and parts made from it are designed for. In most cases, when making a homemade machine, it is optimal to use medium-thick plywood.

- Thus, homemade machines are intended for use at home without changes in temperature and humidity. Thick is used if the machine or its elements, for example, a table for cutting material, require increased strength, then it is better to use a more durable one, with a thickness of 10 mm or more. However, when making any homemade machines, you should initially refuse to use thin plywood, because it is too fragile for such work and is unsuitable for use in the production of a homemade machine.

- When cutting parts up to 6 mm thick, you can use a manual or electric jigsaw. If there is a need to cut a thick sheet exceeding a thickness of 6 mm, a circular saw is used.

- When sawing plywood across the grain, special cuts are made with a knife in order to relieve tension on the wood.

Metal workbench for a mechanic

All useful homemade products and devices simplify the processing of workpieces. Such devices include a workbench for a mechanic. Its minimum dimensions are:

- length – 1800 mm;

- width – 700 mm;

- height – 900 mm.

The table is created in the following sequence:

- frame assembly;

- installation of 2 cabinets, covered with metal;

- securing a working surface consisting of a wooden base in the form of a shield, on which a sheet of metal of a suitable size is placed on top;

- assembly and installation of a rack at the back of the workbench to strengthen the entire structure and accommodate tools.

When assembling a bench, use:

- beams as racks - four corrugated pipes 40*60 mm with a wall thickness of at least 2 mm;

- three beams 50*40 mm to connect the racks and ensure longitudinal rigidity of the structure;

- corrugated pipe 40*30 mm with a wall of at least 1 mm in the amount of 9 pieces to create the frame of the cabinets;

- metal corner 50*50 mm for the manufacture of shelving racks, the height of which will be a maximum of 2000 mm;

- board 50 mm thick for the tabletop panel;

- a sheet of metal no thinner than 6 mm to cover the top surface of the workbench.

Sheet metal Source glavmetall.com

See also: Catalog of construction companies that have their own production of materials and components for the construction of houses

DIY garage press options

Homemade garage presses allow you to process various products and materials under pressure. Structurally, the equipment consists of cylinders. In the garage, such a machine is useful for straightening or fastening various elements, as well as for bending sheets of metal or pressing cardboard.

An example of a homemade press

For private use, a capacity of 10-15 tons is sufficient. Most often, a bottle jack is used with a provided hand pump, which acts as the main structural element.

Here are some interesting options for homemade garage presses:

Option made from scrap materials Rails will also come in handy Ready-made purchased model Convenient homemade press

Do-it-yourself press from a jack: drawings and manufacturing options

There are two ways to create a homemade press from a jack:

- fix the device on the base of the frame to apply upward pressure;

- installing a jack closer to the top of the bed to apply downward pressure.

Here are some helpful plans for creating your own home press:

A simple design option with dimensions With a description of the elements Detailed drawing of the future press Example of a finished device

To choose the right model and dimensions of the future press, you need to take into account several points related to the jack itself:

- its dimensions;

- the magnitude of the working stroke of the rod;

- table thickness;

- height of blanks for pressing.

Watch how to properly assemble a press from a jack with your own hands in the video:

Watch this video on YouTube

Wood lathe for lathe

There are various homemade machines and machines for the workshop. They all make the job easier. These include a lathe. Its structural elements are:

- Durable frame made of metal angle or pipe. Sometimes it is created from wooden blocks. The bed is fixed to the floor, and its lower part is weighted.

- A support, which is a supporting element for the cutters. This part of the machine must provide reliable fixation and allow the workpiece to move to the side. For this purpose, the design provides a screw rod.

- The clamping spindle, also called the headstock. The head of a powerful electric drill is often used as it.

The head of an electric drill is often used as a headstock. Source woodtoolsimg.ru

- Tailstock used for longitudinal movement of the workpiece. It is recommended to use the factory spindle, which has four cams.

- Electric drive providing rotation of 1500 rpm. Its power should be from 250 to 400 W. Often a washing machine motor is used as an electric motor. The design also includes a belt drive. This is a transmission, for the operation of which it is necessary to install pulleys on the shafts.

The electric motor of washing machines is often used as a drive for a lathe. Source dobro-teh.ru

Cutters for the machine

It is recommended to equip homemade devices with factory cutters. After all, they are sharpened with high quality using special equipment. As a last resort, for production use:

- old files without significant defects;

- steel square reinforcement is the optimal material for making cutters;

- square or rectangular spring from the car.

Subsequently, the existing workpieces are sharpened. Creates a semi-circular cutting edge for roughing wood parts. Finish turning work is carried out with a cutter that has a straight blade.

After sharpening, the cutting elements are hardened. During this process, the cutters are first heated and then placed in machine oil.

Wood boring tools for a lathe Source 24aul.ru

Design

Machines, even the least critical ones, cannot use sheets with a thickness of less than 0.6 cm. In any case, this applies to the supporting and load-bearing parts of the assembly. Sometimes an exception is made for housings and other light parts. However, even then you have to carefully weigh the pros and cons in order to give a correct assessment of the selected details. Mistakes in their selection can be fatal.

Some experts believe that a sheet with a thickness of 1 to 1.2 cm is quite enough for individual machines, for example, if we are talking about a cutting table.

Other experts proceed from the fact that parts of large thickness are always needed, even for minor sections of the structure. There is also an opinion that volumetric parts glued together from medium-thick plywood are more effective at damping harmful vibrations during occasional vibration. But real masters always give preference to considerations of reliability and safety. That is why they try to make maximum use of plywood sheets with a thickness of 19 mm or more, despite the heaviness and significant prices.

But you should not focus on just one thickness. The type of original wood must be taken into account. Coniferous wood is lighter and softer, it is used mainly for secondary nodes. Hardwood veneer is more expensive, but is still used more often.

But differences in the chemical composition of adhesives and the level of resistance to moisture practically do not matter; in most cases, FK grade plywood is quite sufficient.

What is much more significant is the veneer category. An increase in the number of knots threatens cracking and delamination. Experienced professionals try to take sheets of second grade and higher. You should not try to buy very cheap unsanded material. Bringing it to the required parameters in artisanal conditions is almost impossible.

Fully sanded workpieces are also easier to glue.

A 4-in-1 plywood machine can be considered as an optimal homemade sample. This design involves the use of a box measuring 54x32x88 cm and a table measuring 65x98 cm. The plywood for these parts is 10 and 18 mm thick, respectively. The cross-section of the disc grinding unit will normally be 18 cm.

To work on wood, you need a different apparatus, the types differ sharply, namely:

- sawing based on a hand-held circular saw;

- jigsaw;

- using a drill;

- universal model, suitable for hanging various devices.

Stationary circulation saw

The stationary circular saw is placed on a sturdy table. Its working surface is usually made of metal sheet. It is reinforced with stiffening ribs. For their manufacture, a steel angle is used.

On the working surface there are usually:

- stops;

- guides;

- elements for adjustment;

- cutting disc.

On a note! The circular saw is powered by an electric motor. Its power should be approximately 800 W, and its rotation should be 1700 rpm. The electric motor of the angle grinder corresponds to these characteristics.

Angle grinder for a stationary circular saw Source tdrim.ru

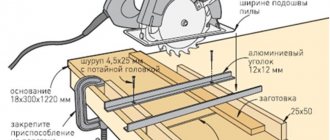

Before making a device for sawing wooden parts, prepare a working angle grinder with the necessary characteristics. Further actions are performed in the following order:

- Assembling the frame.

- Prepare a worktop in which a slot is made for the cutting disc.

- Two wooden blocks are fastened in parallel. They will be used as stops.

- Set the scale necessary to control the cutting of wooden parts.

- Clamps are installed so that workpieces and guides can be fixed.

- The grinder is secured by first installing the disk into the previously created slot in the table top. The power tool is fixed from below the working surface.

Equipment capabilities

What you can do with a planer:

- various furniture for cottages and apartments;

- fence;

- stairs; (See also the article Wooden steps for stairs: features.)

- prepare the cladding;

- renew old wood that has darkened over time.

The photo shows one of the options for a multifunctional wood saw with a cantilever engine located on the side of the circular saw

Drilling machine

Interesting homemade products and devices often help craftsmen out when making various products in the workshop. One such device is a drilling machine. Its main parts include:

- electric drill;

- base made of metal parts with the ability to secure the workpiece;

- a stand for fixing an electric drill, which is created using chipboard with a thickness of 20 to 25 mm or an old photographic enlarger;

- a unit that supplies the drilling tool.

The drill press stand must have guide rails. They are necessary for the electric drill to move strictly in a vertical direction. There are different options for feeding an electric tool, but the most common design is a lever with a spring. It is manually controlled by simply pressing. The design of the machine also includes stops. They are needed to adjust the depth of the hole created in the part.

Pneumatic and electric tools

In Canada there is a settlement of Old Believers who live by their own laws: they do not use electricity, do not ride bicycles or cars. But this does not prevent them from having a carpentry workshop and using compressed air instead of electricity. To achieve this, all rooms are equipped with air ducts from a huge compressor; each workbench has a connection point for pneumatic tools. Using various carpentry tools, Canadian craftsmen are quite capable of making furniture without electricity.

The workshop has huge windows, as electric lighting is not used. All machines operate from compressed air. The external design of the machines does not change, only a pneumatic motor is installed instead of an electric motor. The workstation provides operation of pneumatic screwdrivers, drills, and milling cutters.

Sawing machine

The high speed of the grinder allows it to be used with a saw blade for wood processing. Without some protection this is very dangerous. The craftsmen have come up with a very useful and original homemade device for do-it-yourself carpentry, which allows you to safely use an angle grinder as a sawing machine.

For this purpose, special protection is made, similar to the standard casing that comes with the tool. It has a slide, two handles and a rotating device. The slide looks like a plate measuring 200 x 120 millimeters, with a slot for the saw blade to exit.

Two handles are welded to the casing to hold the sawing machine during operation. It is very convenient to cut and saw thin lumber, and the high speed of the machine on the joiner makes it easy to cut material up to 30 millimeters thick.

Vertical drilling model

The frame can be made from pieces of angle 50x50 millimeters and a steel sheet 5 millimeters thick. To do this, weld two corners along the edges of the sheet along the entire length; they will serve as legs. Table size 350 x 200 millimeters. Weld a bracket from a square pipe 80 millimeters high on top to attach the rack.

The stand or guide for the drill is made of a square pipe three millimeters thick. A section of water pipe eight millimeters long is welded into the upper hole. A cable tensioning mechanism is inserted into it. The height of the stand is 700 millimeters. The stand is inserted into the bracket and crimped with four bolts - two on two sides of the square pipe.

The carriage is a movable unit on which the drill is attached. It is made of 50x50 corners welded together, the height is 170 millimeters, the eyes are made of strip three millimeters thick. An axle is inserted into the eyes, around which the cable is wound.

The carriage drive consists of an axis on which a cable and a handle are wound. One end of the cable is fixed to the bottom bracket. The upper end of the cable is fixed in the pipe at the upper end of the rack. A special bracket with a seat for an electric drill is attached to the carriage. The drill itself is tightened with a special clamp made from a strip 2 mm thick and 40 mm wide.

Homemade turning device

- drive unit;

- bed;

- tailstock;

- handyman

The only difference is in the choice of drive. Whoever has any electromechanical devices is installed on the product:

- electric drill;

- Bulgarian;

- milling cutter;

- electric motor from a washing machine.

You can improve an already made metal-cutting structure by adding additional functions to it. For example, you can place a drill press horizontally on a workbench or table. The drive is an electric drill. The tailstock will be a work table in which a hole is drilled along the axis of the drill in the chuck and a thread is cut for screwing the fixed center.

Additionally, install a hand rest, securing it to the movable bracket of the rack. The workpiece is fastened with one end in a trident clamped in a drill chuck, and the other end in a fixed center. For a small number of simple parts - a quite good homemade woodworking machine with devices and equipment for the manufacture of shaped parts obtained by turning.

The list of tools and mechanisms for a workshop or garage is limited only by the area of the room and the financial capabilities of the owner. Despite the fact that many products are made from waste, the costs of purchasing parts and tools required for assembly are quite significant.

CNC router

There are homemade machines and devices of complex design. Such devices include a CNC router. It is made for processing metal and wooden parts.

Work with a CNC router is carried out to a higher quality. This machine has advanced capabilities. When creating it, an LPT port is used, and numerical control is also provided. The copying unit is created from printer carriages with a matrix of needles.

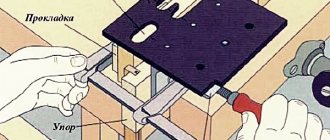

The milling device is assembled as follows:

- The tabletop is made using a plywood sheet. Instead, chipboard with a thickness of at least 15 mm is used.

- A cutout is created to accommodate the cutter.

- The milling unit is installed.

- The electric drive is located.

- The transmission is secured.

- The spindle is mounted.

- The stops are fixed.

The process of creating a wood router Source tmklazer.rf

A CNC milling machine for processing metal workpieces is made with a more durable frame. The device is created in the following sequence:

- The column and frame are mounted when using a channel. From them a structure in the shape of the letter “P” is created. In it, the bridge between two supporting elements is formed by a part that is the base of the milling unit.

- Guides are made from angle iron. They are fixed with bolts on the column.

- Guide consoles are created from a pipe with a rectangular cross-section. To move them to a height of maximum 150 mm, the design provides a car jack.

- A threaded pin is inserted into the console.

- A working surface is created.

- A vice, fixing elements and guides are installed.

- The rotating unit is mounted. In this case, they strictly ensure that the shaft is in a vertical plane.

Peculiarities

Experienced specialists have long known that homemade CNC machines made from plywood are in some cases not inferior to full-fledged factory-made metal analogues. Such structures are used, of course, only where there are no significant mechanical stresses, strong vibrations, heating and the need to remove heat with water.

The technical qualities of plywood devices may well be at a decent level. At the same time, the cost of such equipment is reasonable.

Attention: such systems are designed for private use only. A plywood machine is not useful as a full-fledged production workplace. Before doing it, you need to soberly assess your abilities and knowledge in the field of carpentry. In the absence of special skills and the ability to work with power tools, you will have to forget about making machines yourself.

In addition, you will have to carefully select the main construction material.

Thicknesser

Crafts for the workshop are often created to perform woodworking. The material always has to be planed. It is to solve this problem that a surface planer is made. The machine consists of the following parts:

- The frame consists of two frame structures, which are welded from 40*40 mm corners. The frames are fastened with studs.

- Tabletop made of metal or lumber, pre-impregnated with drying oil. The working surface is bolted to the frame.

Bed with a steel tabletop for thickness planer Source prostanki.com

- A broach consisting of rubber rollers. They are taken from a broken washing machine. The rollers are provided with smooth rotation by sliding them onto bearings.

- A casing that protects rotating parts. It is made of sheet metal about 5 mm thick and fixed to a frame made of corners measuring 20*20 mm.

- Electric motor with a power of 6 kW, which can rotate at a speed of at least 3000 rpm.

Clamps are used to secure the thickness planer. The device is fixed on the working surface. Do not forget about the required gap, when setting it, take into account the thickness of the workpiece.

Wood sanding machine

The design of such a machine has a cylinder on which sandpaper is placed. This unit rotates while processing the part. The assembly of a homemade machine is often performed for grinding cylindrical workpieces. A device is also made to create a flat surface of the workpiece.

When fixing the sanding paper, follow these rules:

- the width of the abrasive cloth should be approximately 250 mm;

- the sanding belt is connected without a gap exclusively end-to-end;

- The sandpaper is attached using a high-quality adhesive;

- at the edges of the shaft for the abrasive cloth there must be a side, the protrusion of which is from 2.5 to 4 mm;

- a rubber backing should be placed under the tape.

The shaft of the device is rotated by an electric motor. These two parts of the machine are connected by a belt drive. The design of the frame itself can have different designs. The option is chosen depending on the size of the workpieces being processed.

Device for polishing wooden parts Source notperfect.ru

Pros and cons of homemade products compared to factory versions

Like every unit, a homemade machine has its advantages and disadvantages. The main one is the cost, which is several times lower in comparison with the factory version. In addition, the advantages of a homemade machine include:

- various manufacturing options . Each of the craftsmen can select the necessary drawing and make a machine that will fully satisfy his requirements;

- energy saving . Homemade machines, as a rule, are equipped with small, low-power electric motors, which can significantly reduce energy consumption.

The disadvantages include the lower accuracy of setting the milling depth compared to factory ones.

Briefly about the main thing

Typically, craftsmen assemble machines for their workshops if the area of the room is at least 3 m2. Universal devices are manufactured or to perform a specific type of work. In addition to shelves and racks, in the workshop you can often find a workbench for carpentry work made of boards and bars, which is equipped with a vice.

Craftsmen also make a metal workbench from corrugated steel pipes, angles, and sheet metal. They also assemble a lathe on a metal frame, with a clamping spindle in the form of a drill head and an electric drive. Also popular in the workshop are a stationary circular saw based on a grinder, a drilling machine made from an electric drill, a surface planer made from an electric planer, and a CNC router.

Selecting materials to create a device

Very often among home craftsmen there are those who try to make their own lathe from an electric drill.

The manufacturing process is not at all complicated, and to achieve the desired result you will need to take all the necessary materials to prepare them in advance. In the production of the machine, woodworking materials can be used, but you should be aware that with such devices you can only process small parts and workpieces, for example, make handles for knives, handles for furniture, etc. If you need a reliable sled that you plan to use very often, then it’s worth investing once and making it out of metal.