Tools used

In this case, the sampling of material is carried out on the surface of the beams and boards from the side. The main thing is that the proposed connection maintains its dimensions in terms of geometry.

To complete the process using a milling cutter, it is possible to use tools equipped with shanks with a diameter of 8 or 12 millimeters. The so-called groove cutter will become a universal option when performing any type of work. The device is equipped with a cutting part, the basic operating principle of which is described as follows:

- The side surface is involved in the formation of the sides of the tenon, the wall part of the grooves.

- The side with the end part is used when processing the bottom. After this, the required layer of material is removed from the base of the spike.

The result is the simultaneous formation of both tenons and grooves on the surface on the sides. The sizes can be individually adjusted, and the owner has quite a wide range of options in this regard.

Sometimes for grooves and tenons they choose not a rectangular shape, but the so-called “dovetail” type. This option is relevant if increased requirements are placed on connection reliability. Accordingly, the cutter used is also called a “dovetail” in this case. Such work can be easily done with hand tools if the need arises.

Guide rail

Having a similar purpose to the rip fence, the tire is responsible for the accurate movement of the cutter in a straight line. The time spent on work is noticeably reduced due to the use of the tire. It also allows you to guide the tool on the table at any angle to the edge.

Some mass-produced tires include a separate component - a shoe. It is connected to the router by rods and, passing along the bus, moves the milling head along a given path.

The tire is best combined with a tool whose base stands on retractable legs. This eliminates the height difference between the guide rail and the router.

It happens that the functionality of commercially produced tires is not suitable for the user. You can always create an individual version of the router guides with your own hands. The most elementary one is a long, even beam - in other words, a ruler. The master only needs to provide it with fasteners, and the tire is essentially ready. To make a simple device, you don’t even need a drawing.

Of course, such a homemade version will not be stable. The combination of a plywood base with a board nailed to it will be more stable in operation. The edge of the router base will rest against the board, and the edge of the base will mark the processing area. This design is used when using cutters of the same diameter.

Another option works when wood cutters can be of different sizes. Here the board acting as a ruler is not nailed to the base, but is reinforced with clamps. Thanks to this, it can adjust the distance from the working area according to the diameter of the cutter.

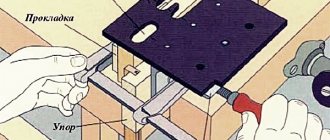

Making a device for picking out a tenon

When parts are processed manually, the milling cutter itself does not have additional spatial fixation. But the overall result of the work and the accuracy of the connection itself in the future depend on this.

To assemble the simplest design that can cope with the task, you will need to use:

- Several guides that remain stationary. They should be side and top or bottom.

- The length of the sample is adjusted through the use of an appropriate movable bar.

For manufacturing, the following sequence of actions is used:

- A plywood sheet is taken, from one edge of which the side elements are mounted in a vertical plane. It is necessary to create appropriate cutouts in the center of the material.

- The sides are equipped with guides. The base of the hand cutter moves along them later.

- The side strips are fixed on the upper guides. Then the movement of the working milling cutter associated with these parts becomes limited.

- The plywood sheet, which became the basis for the installation, also serves as a surface for installing the moving element. Then the amount of edge overhang for the future workpiece is easier to control under any circumstances. Fixation is ensured with ordinary screws and other types of fixing devices.

Circle milling

To perform tasks at home, a device that can make it easier to cut round blanks may be useful.

For example, a compass is often used, which you can create with your own hands.

This device is made according to the following scheme:

From available elements, a piece of plywood, self-tapping screws, a wooden wing and a bolt with a nut are used to make the device. You will also need a router, saw and screwdriver. A small marking is made on a piece of plywood. A platform is outlined on it, the length of which is 15 cm and the width is 5 cm.

It is important that the length exceeds the processing radius, and the width exceeds the size of the router pad. Holes are made for the mounting bolts (their diameter is 2-3 cm). Perka is used for drilling. A groove is cut through the middle strip

It is necessary to ensure that its width does not exceed the size of the axle bolt. A recess is made at the bottom of the plywood sheet to accommodate the nut and washer. Another nut is secured in a wooden wing. Now you can assemble the main axis. Instead of a stud, use a bolt with a sufficient length, having first sawed off its head. The compass is installed on the router and the functionality is checked.

Creating tenons on bars and boards

Processing is performed using the following sequence of actions:

- The part to be processed is mounted on a plane from the bottom side.

- The edge of the part where the tenon is formed accommodates the cutouts at the guides at the top. The structure moves inward until it hits the end.

- A movable type element must be fixed while maintaining a certain position.

- We use a wedge tool to connect the guides and the plane located at the top to each other.

- Connection of a hand router with the upper guides.

- Using a router tool on a home router table, wood is removed from one side.

- When the first side of the workpiece is processed, begin the second.

The operation will be successful only with high performance and accuracy parameters. Setup refers to the required steps before the instruments are turned on. To resolve the issue, actions are performed in the following sequence:

- The milling tool is lowered until it reaches the surface of the base.

- Measuring the thickness of a part.

- The thickness result is divided by 4. The result is the distance parameter that is maintained when lifting the cutter above the base.

Selecting the right equipment

A manual milling machine is selected according to the type of work and the planned load. There are main types of equipment for woodworking:

- vertical – top type;

- lamellar;

- edge

Horizontal lamellar router. A disk with teeth along the edge moves parallel to the sole and cuts grooves in the side surface for flat keys in the mating parts without marking. The use of the tool is narrow. The lamellar type of tool is in demand in the production of furniture and building wooden structures. It is rarely purchased for a home workshop if the owner is seriously interested in making furniture and has models of universal hand routers available.

The top type router is universal for wood processing. It is he who is capable of performing almost all operations. Its kit includes several devices that allow you to process the ends and work along the plane of the board. Basically this is a parallel fence with rods, milling bushings and a set of cutters of various types. The former guide the machine exactly along a straight cutting line or help make an even circle. The bushings guide the machine along the template, repeating its shape of any complexity.

To make grooves, cuts for locks and canopies, and create beautiful edges of any configuration in wood, a top-type router is suitable.

Wood cutter "Dovetail"

For mortises and tenons under similar circumstances: only half the normal width. This is explained by the characteristics that compounds of this type have.

The main thing is to set up the device correctly and fix it in a suitable position.

The tongue-and-groove joint should end up with some clearance. It is necessary so that later you can conveniently use the adhesive composition.

Guide rail

use a piece of chipboard

First you need to find out the distance from the edge of the milling base to the center of rotation, and it is always the same. To do this, you need to screw a guide to the unnecessary part of the material and make a test cut. Then you should measure the gap from the edge of the cut to the tire, to which the radius of the cutter is added. As a result, it will be possible to obtain the required value. For example, it is 59 mm, and the diameter of the groove cutter is 14 mm, that is, its radius is 7 mm.

Then you should draw a line for the cut, from which we retreat a distance of 52 mm (59-7), and draw another one. We fix the guide along it and make the cut.

How to choose a groove with a router?

The solution to the problem depends on where the grooves are located and what size they are. Here are some recommendations for home craftsmen:

- The use of open grooves involves securing it to the tabletop and guiding the workpiece along the cutter.

- Accuracy is determined by the height of the cutter and the location of the bar.

- It is recommended to use wood waste for trial operations. This allows you to avoid mistakes.

- Sampling is carried out in stages, with several passes being carried out.

The main thing is to get rid of wood waste in a timely manner after completing each stage. Then the instrument will definitely not suffer from overheating. When doing the work, it is easiest to use a template cut out of plywood. They pass through it with the cutter itself, with the bearing installed.

Processing of wooden parts

The first thing you need to learn is to correctly set the milling depth. To do this, you need to set the zero point. It is impossible to set it rigidly, because it changes every time the cutter is changed. The zero point is the position of the tool when the end of the cutter touches the material and is fixed with a special device called a clamp.

It is necessary to pay attention to the fact that each router has a different position when fixed. To control the depth of immersion of the cutting tool into the body of the material, a stop pin with a coarse adjustment scale is used.

When milling with an end mill, the counterforce from the cutting force moves the router to the side. To prevent this from happening, you need to use a rip fence. The milling process is as follows. Place the cutter along the marking line and secure the position of the stop with a special screw. Set the milling depth and turn on the machine. If the rip fence is installed on the left side, you need to pull the router towards you, when on the right side - away from you.

In order to select a quarter on a beam, you need to set the cutting edge of the cutter at the very edge, fix it, set the depth of the quarter, turn on the router and pull it towards you (if the stop is on the left edge of the beam). Milling the surface of narrow bars has its own peculiarity. The problem is that it is very difficult to hold the router on the narrow side of the workpiece. If it wobbles during operation, the groove will be inaccurate.

Working with a hand router can replace working with a planing machine. To do this, you will need several accessories for the milling mechanism. It looks like this: attach a milling mechanism to two equal-sized slats and use it as a planer, where a large-diameter milling cutter is installed instead of a shaft.