An electric or regular jigsaw is useful for a creative craftsman, since the equipment allows you to cut shaped or straight cuts from a wide variety of materials, from soft wood to glass or even steel. The versatility of the tool lies in the files, each of which serves a specific task. Therefore, it is very important to understand their classification and know how the file is secured in the jigsaw clamps.

Jigsaw

Classification of jigsaw files by type of material being processed

Initially, when jigsaws were not yet electric, this equipment was used only for wood processing. But modern devices allow you to cut metal, plastic and any type of wood surface. Therefore, before purchasing a jigsaw (Bosch, Makita or similar models), you need to decide on the material to be processed. After all, depending on the purpose, you will have to look for a specific cutting blade.

For wood and wood materials

Files for wood processing are divided into several groups:

- Quick cut Sometimes the quality of processing of wood material is not as important as the speed of the process itself. For such work, a long blade (from 60 mm) with large teeth (up to 6 mm) is suitable. If the master is going to make a longitudinal cut, then it is advisable to buy files with oblique teeth. And for a cross cut, a straight “tooth” is used.

- Clean cut (average tooth size not exceeding 3 mm, as well as a slight gap). Such files are usually used in furniture assembly plants.

- Figured cut. It is difficult to make a curved cut with a small radius, so special shaped files are used that have a very narrow blade, not exceeding 4 mm. The canvas is also characterized by small teeth (up to 2 mm) and short length (40 mm).

Important! If you choose the wrong file, there is a risk of overheating the motor of the jigsaw (models Dexter, Whirlwind and others).

For metal

Cutting metal is not the most obvious solution when working with a jigsaw, but this is possible thanks to a special blade. But, it should be borne in mind that the process will be very slow, and you will have to change a lot of files, as they become dull.

Experts recommend keeping three types of metal cutters with you at once if the master often works with this material:

- for aluminum;

- for non-ferrous metals;

- for steel.

If these blades are rarely used, you don’t have to spend money on buying additional ones, but choose only one - for processing steel. It will cope with non-ferrous metals and aluminum, but will become dull very quickly.

Attention! Metal files are made of durable steel; they have very small teeth (up to 1 mm), which are arranged in a wave-like manner.

Types of jigsaw blades

For polymer materials

To process PVC pipes or other similar materials, it is necessary to use blades with large teeth. Small ones will also work, but you will have to use the maximum speed of the jigsaw, otherwise the melted plastic will begin to clog the cutter.

If you have to work with thin sheets of plastic or plexiglass, experts advise using blades for metal processing. To cut thick plastic, you can take wood saws, but work at low speeds.

For specific tasks

There are special blades for processing ceramics and glass. They are coated with diamond coating or tungsten carbide.

It is advisable to use an electric jigsaw (Dexter, Diold and other models) for processing ceramic tiles or glass only if it is necessary to make very complex shaped elements. For straight cuts, it is advisable to use tools designed specifically for this purpose.

When sawing cement or plaster with a jigsaw, you will have to buy special files with carbide tips on the cutting edge.

In stores you can also find files that are suitable for processing rubber, cardboard and other soft materials. There are practically no teeth on them, and the cutting edge is a polished wave.

Universal

These types of blades are made from high-speed steel. They are suitable for processing different materials: plastic, wood, metal.

You shouldn’t expect high-quality cuts from such tools precisely because of their versatility - a specific material requires the use of a special blade (this is the key to a high-quality cut).

Types of jigsaws

Before moving on to the immediate specifics describing the process of installing a file, it is worth clarifying the types of tools involved.

Since the jigsaw device has quite a few incarnations, we inform you in advance that in this guide we will touch on 3 of its varieties: manual, electric and stationary. A band saw, which is also sometimes called a jigsaw, will not appear in this article. Now a few words about each type of device under consideration. Hand jigsaw

The cheapest option for a tool for making figured cuts in wood and its derivatives. When using special blades, it can be used for cutting metal of small thickness. The speed of work and the quality of the cut depend entirely on the experience and physical characteristics of the worker. Quite easy to use and does not require hours of study.

Electric jigsaw

A more advanced and expensive type of tool for making straight, transverse, inclined and figured cuts. Depending on the installed saw blades, it can work with wood, plastic, metal and even ceramics. It has a high saw stroke frequency, which usually reduces the quality and accuracy of the cut. Sometimes an electric jigsaw is rightly called a manual jigsaw, since it must be held during use. This tool is considered one of the most popular in everyday life, second in popularity only to the screwdriver and drill.

Stationary jigsaw

A very convenient and functional machine for amateur and professional work. Widely used in industry and at home. It works with thin files like a manual jigsaw, but the cutting speed is not inferior to an electric one. The main advantage of using a stationary jigsaw machine is complete freedom of both hands, which allows you to more accurately control the position of the workpiece during processing. The device copes well with straight cuts, but is primarily intended for figured cuts.

Having finished with a brief description of the devices, you can move on to the main question of the article. Let's look at how to insert a blade into a jigsaw and what nuances should be taken into account. Let's start with electric models.

What can a saw holder be like?

The saw holder is the most vulnerable part in the unit under consideration. It is he who is subjected to the heaviest loads during work, and accordingly fails.

The material for the saw holder is usually of the highest quality, but not all manufacturers take care of this, so the percentage of replacement units on jigsaws is high.

There are three types of holder, and each has its own characteristics, how to install a file in a jigsaw.

Saw holder

Bolt-on clamp (shoe) mount

This is the first option that began to be used on electric jigsaws. Almost all modern manufacturers have already abandoned block fastening, since replacing the cutting part in this case is a labor-intensive process: unscrew two bolts, install a file, and then fasten them back. For this operation you need to have a hex wrench with you.

Quick release mount

Used on many modern jigsaws. The process of replacing the blade takes no more than a minute, since you only need to press a special button to loosen the clamp and insert a new file there.

Radial clamp

The simplest type of fastening. Used on new models of jigsaws. To simplify operation, it is equipped with a spring that returns the cams to their initial position.

Important! When replacing the cutting part, it is important to pay attention to the fastening units, since they most often fail. Over time, play appears there, causing the file to beat, which affects the evenness of the cut.

Blade clamp repair

Unfortunately, many manufacturers of power tools often skimp on materials, which reduces the service life of manufactured devices. The clamp for the jigsaw file, which is subject to serious pressure during operation, is also subject to periodic breakdowns. Below, we will tell you what can happen to the block fastening and how to fix the damage. During prolonged use of the jigsaw, due to the loads on the blade fastening unit, the block clamp can be seriously deformed. Damage can be minor, expressed by slight deformation of the pad, or very serious, turning the part into a useless piece of metal.

The easiest option for restoring the functionality of your jigsaw is to purchase and install a new, identical block. A similar element can be found in construction markets and tool stores. Fortunately, such details occur quite often. At the same time, it is not a fact that the quality of the new mount will be better or at least no worse than the old one. The main thing is that the tool can be used. See below for a video on installing a new pad. A longer and more reliable option is suitable for advanced craftsmen with experience and a set of necessary equipment. The next method is to make a saw blade holder for a jigsaw with your own hands. To make your own pad, you will need:

- Piece of steel: 18x15x15 (length, width, height)

- Hacksaw for metal

- Grinder with a metal disc (preferably diamond)

- Drill with 4 mm metal drill

- Vise

- Ruler or caliper

The manufacturing process is extremely clear for an experienced tinsmith, but for greater clarity it is demonstrated in the following photos.

If you do not have enough skills in working with metal, we recommend that you take the following drawing to the nearest turning workshop, where the part will be made to order.How to insert a file into a jigsaw

Shoe mount - how to insert a file into a jigsaw:

- Loosen the block by turning the two bolts counterclockwise.

- The canvas is placed with the teeth forward.

- The bolts are tightened evenly to their original position.

It is important to ensure that there is no skew, otherwise the cut will be uneven.

If only a bolt is installed on the block, then it needs to be loosened and tightened. There is no need to tighten the screw all the way, as unnecessary vibration will be created during operation. This data is enough to understand how to insert a file into a jigsaw with a block mount.

Quick-release technology - procedure:

- Press and hold a special key.

- Insert the shank of the file into the corresponding slot.

- The key can be released.

If you hear a click, it means the operation was successful.

The easiest replacement option is with radial mounting, but you need to choose the correct shank shape (there are U-shaped and T-shaped). The second option is the most common; the u-shaped model has special holes for additional fixation.

Jigsaw with file

How to change a file on a jigsaw:

- Rotate the device head 90 degrees.

- Insert the fabric into the special slot.

- Release the jigsaw.

The clamp will return to its original position under the action of the spring.

Jigsaw Interskol: correction of sawing curvature

It is worth paying attention to the domestically produced Interskol jigsaw.

It is produced in Izhevsk. For household use, this is a completely acceptable option. It has many positive qualities, and the most impressive is its low cost. But there are also disadvantages

For domestic use this is a completely acceptable option. It has many positive qualities, and the most impressive is its low cost. But there are also disadvantages.

Replacing the quick release saw blade mount

This is the curvature of the saw. What is the problem, and is it possible to get rid of it? The culprit was the quick-release fastening of the file. The fact is that it is designed for saw blades of maximum thickness. All cutting tools of smaller thickness simply dangle in the mount.

How to get out of this situation? You need to replace the quick-release mount with a simple device with regular bolts. It's not difficult to make. You need to take a square rod, cut two blanks, drill holes in them and connect them with two M5 bolts and nuts. The procedure for attaching the saw blade will become somewhat more complicated, but the tool will produce an even cut.

Refinement of jigsaw design

In addition, you can modify the design of the tool itself and limit the movement of the file in the transverse plane.

To do this you need:

- take sheet aluminum and cut the plate to the size of the jigsaw sole;

- In the front part of the workpiece, it is necessary to make a cut to the size of the working area of the cutting tool. File all edges, make bevels on the inner longitudinal edges of the cutout;

- You need to cut a plate from plexiglass to the size of the working area of the saw blade. File all sharp edges and make reverse bevels on the outer longitudinal edges;

- The aluminum plate must be marked for its installation on the jigsaw base. Drill holes and make chamfers for installing countersunk screws;

- A piece of plexiglass must be inserted into an aluminum plate, having first made a cut at its location.

Now, during operation, the saw blade will be limited in transverse movement almost in the cutting zone, which will give it even greater straightness.

Installation in jigsaw machine

A jigsaw machine is a comfortable device, since both hands of the master will remain free when working, which allows for more manipulations.

Attention! To use the device, it is advisable to use special blades with a pin for reliable fastening. If you buy a sample without a pin, you need to tighten it more carefully.

How to properly secure a file in jigsaw clamps:

- Secure the canvas in special grooves (first in the lower part, and then in the upper).

- The teeth should point down and away from the person standing behind the machine.

- The fabric is tightened using a special lever.

If the file is tightened correctly, then after a slight blow it should ring. If the canvas does not have a font, then it must be secured very carefully, since it often jumps out of the device.

Jigsaw machine

The lineup

The Japanese brand Makita offers its customers a huge selection of various models of jigsaws, each of which is distinguished by high quality and reliability.

Let's look at the most popular options.

Makita 4236

The model is rightfully considered the first tool of a beginning master. The jigsaw is incredibly easy to use and has all the functions you need at first. Suitable for cutting plastic, wood and metal products. The model boasts the ability to perform straight and intricate cuts.

Moreover, the affordable price is good news - it starts at 3,000 rubles, which is quite good for such a successful purchase.

Makita 4329

It is already equipped with a large number of functions and is intended for those who, so to speak, have gotten a taste for it. Here is a speed control system that can be customized depending on the characteristics of the material - wood, metal or plastic. Thanks to the presence of a pendulum stroke, the speed at which the device operates increases. And there is also a function for tilting the sole to make cuts at an angle.

A disadvantage is the lack of a sawdust blowing system, which is not always convenient when working.

Makita JV0600K

The model is ideal for constant work in any workshop, since it positions itself as a truly reliable unit with increased electric motor power and overheating protection. An excellent addition is the speed control function.

The disadvantages include quite a lot of weight and the fact that the price starts at 6,000 rubles.

Makita 4350CT

This model is the most powerful jigsaw of the Japanese brand. It is designed to work with a wide variety of wood types, laminated, chipboard or MDF. It is also suitable for cutting ferrous and non-ferrous metals, stainless steel and plastic into pieces. A reliable control system and effective engine ventilation ensure long-term and continuous operation of the device.

The downside is the lack of lighting in the cutting area. Also, the sole is not accurately positioned horizontally, so the worker requires increased care.

Makita JV100DZ

This model can be called one of the most popular among cordless jigsaws. First of all, it attracts with its price - 4,000 rubles for a cordless jigsaw is quite inexpensive. Like a classic network tool, it performs the most necessary functions: it works great on wood, metal and plastic. The metal sole helps well in the cutting process.

Possible problems

When working with jigsaws, certain problems may arise that need to be resolved in time:

- The blade latches fail. They should not be overtightened so as not to break the thread.

- Fastening bolts, which gradually wear off during intensive work, are also subject to timely replacement.

- You should always pay attention to the condition of the file, as it can deteriorate and cause the engine to overheat. And also, if the master works with a dull file, the quality of the work decreases.

- The blades may become distorted, which will affect the processing of the material.

- When working with a dull saw, the wood will char (this is the wrong working technology).

- If you do not lubricate the roller in an electric jigsaw in time (for example, in a Bosch or Zubr model), the motor will overload.

- When working with an electric jigsaw, do not use excessive force, as the blade clamp may be damaged.

- Electrical devices need to be given time to cool down.

This information is enough to understand how to secure a file in a manual jigsaw, as well as maintain the device (for example, Interskol models) in working condition.

Jigsaw: features, design and advantages

This tool is a very useful acquisition for the home workshop. It has many functions, you can work with it in various conditions and in almost any position.

Jigsaw device.

Thanks to modern achievements and high technology, a jigsaw has ceased to be just a hand tool. After all, the use of an electric or pneumatic drive in its operation makes the jigsaw an almost universal household tool. It has also been improved with built-in safety features, noise and vibration dampers, electronic speed control and anti-touch (saw blade) protection.

In a nutshell, the principle of operation of a jigsaw can be described as follows: torque from the engine is converted into movement, due to which the saw moves further forward in the vertical direction.

Jigsaw design

Conventionally, the entire structure of the instrument can be divided into the following parts:

- motor housing;

- gearbox;

- sole;

- handle.

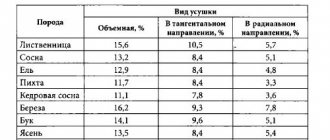

Table on the use of files.

If the handle is bracket-shaped, then the machine will be a closed structure, and you can keep your palm on the handle exclusively from above. The mushroom handle option can be grasped in different ways, as well as calmly changing the position of your hand.

It is necessary to ensure that the sole and body are firmly connected to each other, because even the slightest play can negatively affect how the tool will work.

The sole of the jigsaw is placed on the surface that you are sawing off. Files (or saw blades) cannot be sharpened; they simply need to be replaced. The tool will not overheat or experience additional overload if you promptly replace a dull file.

Jigsaws: main types

They are all the same in purpose and design. But there are several types of tools depending on how the file is attached to the jigsaw.

- For saws with a cross-type shank.

- For saws with a smooth shank.

- For a saw with a shank that has a hole.

Video description

The process of replacing equipment in a jigsaw with a jig saw is shown in the video:

If in quick-clamp fasteners the file is automatically fixed in the desired position, then in jigsaws it needs to be controlled, which for many is a noticeable disadvantage, as it takes time. In addition, it is important to correctly determine the degree of tightening of the bolts. If you clamp too hard, the blade will be very tense and may break. And if it is weak, it will fall out or dangle in the socket, and working with a jigsaw will become impossible.

The second problem with such fasteners is the abrasion of the slots on the bolts during intensive work and frequent replacement of saw blades. Often the threads of the fastener or block break and cracks appear on its body. This mainly happens with tools made in China from low-quality materials. A damaged pad cannot be repaired, it can only be replaced.

How to use a hand jigsaw

In this lesson we will show you the basics of working with a regular hand jigsaw.

Of course, there are also electric jigsaws, but they cost a lot of money, and working with them is a pursuit of speed, and not a calm, moderate creation of beauty. For work we will need: a hand jigsaw, a file, a table stand, a clamp for attaching the stand to the table, an awl, a pencil, two paper clips, a sheet of tracing paper, a sheet of copy paper, sandpaper and of course a piece of plywood of the required size. We will cut out a Christmas tree; in this work, in addition to the cutting technique, we will also master the technique of assembling plywood parts into a three-dimensional Christmas tree shape and the easiest way to finish the finished product, using ordinary watercolor paint.

The size of the plywood should correspond to the pattern you have chosen; try to arrange the cut parts more compactly, closer to each other, since everything that remains after cutting, as a rule, can no longer be used in further work due to its fragility. And so we clean the selected piece of plywood with sandpaper, trying to move it along the fibers, since transverse scratches will be very visible on the finished product and are very difficult to remove later, and the treated plywood looks velvety and soft.

The sandpaper should be medium-grit to reduce scratching of the plywood.

Secure the sheet of tracing paper and the drawing using clamps, then use a pencil to copy the drawing onto the tracing paper. This operation is necessary in order not to damage the original drawing when transferring it to plywood.

It should be noted right away that with the current level of distribution and availability of copying machines, for large-scale and complex drawings, it is good to use a copying machine for cutting and the required drawing simply needs to be copied onto a blank sheet of paper and then transferred from there to the plywood. The advantage of this method is that it is quite easy to enlarge or reduce the pattern chosen for work. We put tracing paper with a design on the plywood and use a pencil to transfer it through carbon paper to the front side of it.

Having transferred the entire drawing to plywood, we carefully check whether all the lines of the drawing are clearly visible on the plywood.

At the next stage, it is very important to check the future joints of the herringbone parts. To do this, a piece of plywood of the same thickness as we are using needs to be attached to the drawn groove of the Christmas tree part and make sure that it fits exactly within the drawn boundaries. If the dimensions of the groove and the thickness of the plywood do not match, the width of the groove is adjusted - it is drawn equal to the thickness of the plywood used. Otherwise, when assembling finished parts, they will hang out or simply not fit into each other. This way all grooves in all part drawings are checked.

We take the stand and insert its clamp into the central hole.

We fasten the stand with a clamp to the edge of a table, window sill or workbench.

If your file is not inserted into the jigsaw, then we do this in the following sequence. We loosen the thumb of the lower clamp of the jigsaw (after turning the handle down to the working position). Insert the file into the lower clamp.

The direction of the saw teeth should be as in figure “b” - this is very important.

Then, having loosened the knob of the upper clamp, insert the upper end of the file into it and placing the jigsaw on the stand, press it firmly and screw the knob tightly. The file should be taut. But excessively strong tension can lead to breakage of the file when cutting shapes, and weak tension on the file will also lead to the same. So everything should be in moderation.

The position of the body when cutting should be as in the figure.

When cutting with a jigsaw, you need to smoothly move your hand up and down, up and down, monitoring the position of the file so that it does not tilt from the vertical position. When cutting along a curved line, turn the plywood rather than the jigsaw during the sawing process - this will reduce the likelihood of breaking the file.

When cutting sharp corners, make movements of the saw in place, gradually turning the plywood.

You should have a free space - a hole in which the file will turn, now continue sawing in the desired direction.

Make free space for turning the saw on the part of the plywood that will be thrown away and you will get sharp corners without much difficulty.