Drywall has become an integral part of our lives - both as a building material and as a cladding. Most manufacturers recommend mounting plasterboard structures on metal profiles. We discussed in detail the process of installing a frame made of a metal profile in this article. But is it possible to install drywall on a wooden frame? Certainly! and we will tell you how to do it competently and quickly.

Combined use of wood and metal profiles

Necessary tools and materials for work

To construct a wooden frame for cladding walls and suspended ceilings, you need the following tools:

- level;

- measuring instruments - ruler, tape measure;

- manual or electric wood cutting tools;

- drill, screwdriver;

- hammer.

Tools required for installing drywall on wood sheathing

Materials:

- wooden beam, its size depends on the purpose of constructing the structure - to insulate or soundproof a wall, the profile of the beam must be no less than the thickness of the gasket material by 4-5 cm; for leveling wall cladding - timber section 8.0x2.5 cm for racks (vertical system) or beams (horizontal), 4.0x2.5 cm for spacers;

- for sound insulation - a special gasket;

- plasterboard - depending on the purpose of the room, ordinary, moisture-resistant, fire-resistant;

- reinforcing tape for seams;

- putty;

- primer;

- finishing material.

ATTENTION! When facing plasterboard with slab materials, the lining must be done in 2 layers!

For work at height, you will need a stepladder or scaffolding.

Worker protection is required - clothing, gloves, glasses, respirator, shoes with non-slip soles.

GKL against plaster

First, let's decide whether it's worth messing with drywall at all or whether it's better to use plaster the old fashioned way.

Here are the arguments in favor of gypsum boards:

- High finishing speed due to the large sheet area (3 square meters with a size of 2500x1200 mm);

- Possibility to eliminate significant unevenness of the base at minimal cost. Let's say, if the height difference between adjacent elements of a slab floor is 8-10 centimeters (yes, yes, this also happens), leveling the ceiling with plaster is very expensive and unsafe: the fall of peeling plaster of such thickness can cause a lot of trouble.

But for gypsum boards on the sheathing, the condition of the surface underneath does not matter at all - as long as there is something to attach the frame to;

It is easier and cheaper to level an uneven and littered wall with plasterboard.

- The surface of kraft paper (gypsum core shell) has excellent adhesive properties. You can glue wallpaper of any density to it using any wallpaper glue; tiles also adhere perfectly to cement tile adhesive or homemade cement-based mortar.

Ceramic tiles adhere perfectly to drywall using any tile adhesive.

And not only them. How does drywall compare to plaster?

- Mechanical strength. Let me clarify: in this parameter, gypsum sheet material is second only to cement plaster. Using gypsum board to decorate walls in a gym or workshop is a dubious idea;

- Resistant to water with constant contact with it. Alas, even moisture-resistant drywall only tolerates high air humidity. If you immerse a gypsum core in water, it will get wet just like any other gypsum product. Accordingly, it would be a bad idea to use gypsum board without protection with a waterproof finishing finish for the construction of shower walls;

- Occupied usable area of the room. It is better to level walls with minor unevenness in a small room with a thin layer of plaster: even when glued directly to the wall, without lathing, a sheet of plasterboard, taking into account the thickness of the glue, will shift the surface of each wall by at least 20 mm. When mounted on a frame, each wall will move towards the center of the room by 60 - 80 mm.

The space under the sheathing is wasted.

How to calculate the amount of fasteners

The frame elements are attached to the enclosing structures directly with dowels, the frame for plasterboard in a wooden house - with nails, and when attached using special hangers - with self-tapping screws. Calculation of fasteners depends on the method of fastening, the selected pitch of racks and spacers.

The frame is fastened to the base using dowel-nails (in wood, concrete, brick) or dowel-screws (porous materials - gas, expanded clay, foam concrete) 6x40 at the rate of 1.6 per square meter.

The frames of interior partitions are attached to anchor bolts.

The wooden blocks are fastened together with wood screws - 2.7 per 1m2.

To fasten the cladding, use self-tapping screws 20 mm long with a pitch of 100...120 mm with a conical head - 17 pcs. per m2.

For a suspended ceiling, consumption of hardware per m2: anchor dowels (attaching suspensions to the ceiling) 0.7;

- screws (fastening the frame to the hangers) 3.5x9 - 1.4;

- wood screws (fastening frame elements to each other) 0.7;

- self-tapping screws (gypsum board fastening) 23.

The main mistakes made when covering walls with plasterboard

To get a good result and an even coating prepared for finishing work, the main thing is not to make mistakes during the installation process. A list of common mistakes when you decide to cover walls with plasterboard yourself:

- Incorrect installation of profiles. The profile should have its smooth side facing down. It is worth cutting it carefully and only with metal scissors in order to preserve the opposite shelf, where the drywall will be attached next, without damage. The use of hangers cannot be neglected;

- choosing the wrong types of profiles;

- unbending of parts of the profile, which leads to a decrease in the strength of the entire surface;

- installation of gypsum boards on the wrong side. Especially if a waterproof profile is used, for example in a bathroom, then installing it with the reverse side facing the room, all waterproof properties are simply lost;

- improper fastening of the sheets, they should be fastened at intervals, only then the structure will be reliable.

The profile should have its smooth side facing down.

You can cover the walls with plasterboard yourself. But you need to strictly follow the work technology, not missing out on details that may seem insignificant, but in the end will play a big role on the quality of the resulting surface. Doing the work yourself will reduce the cost of repairs.

Selection and preparation of wood for the frame

Is it possible to attach drywall to wooden blocks? Yes, if you choose the right material and process it. Drywall over a wooden frame in a wooden house is especially appropriate if you don’t like the lining or timber in the interior.

The best option for frames is coniferous wood; unlike hardwood, it absorbs less moisture and is less susceptible to damage by insects, rot, and disease. But to increase the service life, any timber requires protection from pests and diseases, and increased resistance to combustion.

The process of fitting wooden sheathing to drywall

The timber is primed, successively coated in 2 layers with a fungicide (if bugs, mold, rotting are noticed, then with an antiseptic and fire retardant. Each layer is applied after the previous one has completely dried.

A wooden frame for plasterboard used in a residential area cannot be treated with compounds containing coal or shale tars

The period of preparatory work is reduced by the use of complex compounds that guarantee protection for up to 25 years, but their price is much higher.

Advantages

When the lathing is made from wood with your own hands, the home craftsman gains many advantages. Firstly, such a frame does not form cold bridges, which cannot be said about a metal profile. The internal cavities will only need to be filled with insulating material, which will also soundproof the walls. Secondly, installation work using wooden blocks is somewhat easier to carry out, because it can be difficult to deal with load-bearing, rack and guide profiles. Thirdly, all the disadvantages of wood such as fire hazard and susceptibility to insects can be eliminated by treating the material before installation with fire retardants and compounds that ensure biological inertness.

Marking

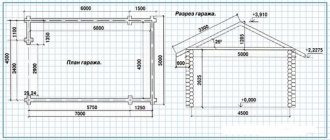

You should first make a drawing (diagram) of the frame with the layout of the plasterboard, you can draw it by hand, the main thing is that the main and additional structural elements and attachment points are visible. According to the diagram, the dimensions and number of frame elements and fasteners, the area of the facing material, the amount of impregnation and finishing are calculated.

An example of marking a frame for drywall

The size of a regular gypsum board sheet is 1.2x2.5...3.0 m. Based on this size, the frame pitch is selected. GKL sheets can be mounted in a horizontal or vertical direction, respectively, the load-bearing elements will be located parallel with a step of 0.6 m in the axes, the spacers will be perpendicular, with the same step.

Dimensions for constructing a frame for a standard sheet of drywall

The choice of direction depends on the features of the partition - openings of windows, doors, decorative niches, on the ceiling - different levels, location of lamps. The design is planned in such a way as to reduce the amount of cutting of gypsum boards and minimize waste.

An example of wood lathing for plasterboard

Marking of fasteners and beams is carried out on the fence of the room with a marker or pencil according to the diagram. For vertical and horizontal alignment, bubble or electronic levels and plumb lines are used.

Preparatory stage

Drywall is a finishing material characterized by durability. It is this fact that makes us think about carrying out preventive treatment of all surfaces that will be hidden behind gypsum board sheets. The owner of the building can only find out that fungus has appeared on the surface of the main walls or mold has grown at the moment when the structure, erected several years ago, begins to crumble and collapse.

Natural wood is a fire hazard. Therefore, all surfaces should be thoroughly treated with antifungal agents. The gaps between the beams must be caulked with tow, impregnated with compounds that ensure the structure’s ability to resist fire. Silicone or foam can be used as an additional treatment.

Foaming cracks

All components of the structure are pre-cut or sawn into separate pieces, the length of which is determined after accurate measurements are taken. This applies not only to the contour. Longitudinal (rack-mount) guides and jumpers are prepared in advance.

Assembling a wooden frame

If space allows, the frame is assembled in a horizontal position, and then raised and attached to the wall, but more often it is necessary to assemble the structure element by element simultaneously with fastening.

The frame of the separate partition is fixed to the timber frame in the following sequence:

- lower horizontal support beam;

- side racks;

- upper closing beam;

- racks and beams for framing window and door openings;

- intermediate posts or beams;

- spacers

The process of installing a frame under plasterboard

The bars are secured to each other using corners.

Installation of the frame of the partition leaning against the wall:

- horizontal support beam (attached to the floor);

- fastening the main load-bearing elements in a horizontal or vertical layout;

- spacers (attached to the main beam).

Ready frame for drywall

Lathing on hangers

Installation will be speeded up by installing the sheathing on hangers - fastening elements of the steel frame for plasterboard.

Drywall frame with direct hangers

Work order:

- suspension profiles are attached to the enclosing wall or ceiling with dowels;

- then a beam is placed, the sides of the suspension are bent, the horizontal and vertical are checked;

- temporarily secured with nails in several places;

- attach each beam to the hangers with self-tapping screws on both sides;

- install and secure spacers.

If it is necessary to reduce the height of the room, the suspensions are aimed at the ceiling, a beam of the appropriate length is attached vertically to each suspension, guides are mounted to the suspension bars, and spacers are installed between the guides.

Schematic representation of a wooden frame for plasterboard on hangers

Lathing on spacers

In order not to level the wall under the sheathing, unevenness can be leveled with spacers. To do this, cords are pulled vertically and horizontally along the perimeter of the future frame, taking into account maximum irregularities. When shooting the sheathing elements or hangers with dowels, a gasket of the required thickness is laid at each fastening point. The method reduces construction time, saves money, but requires great care and careful alignment of levels.

Construction of a brick partition

How to make partitions in a brick bath? This material is quite common and is often used for the construction of buildings in the bathhouse.

The construction is made using half-brick spoon masonry.

To make work easier, some specialists use hollow material.

Preparatory procedures

Before starting work, you need to carefully prepare the surface. The plank covering is removed from the floor to the very base, after which it is cleaned with a wet broom. The place where the construction will be carried out is equipped with good lighting. All foreign objects are removed from the premises and the outlines of the building are outlined.

To work you will need to prepare the following tools:

- level;

- sander;

- trowel;

- plumb line and rule;

- cement-sand mortar. For more information about the construction of a partition, watch this video:

Creating a partition

The process of erecting a brick partition consists of the following stages:

- A string is stretched and used as a guide. The solution is laid and leveled using a trowel. The level checks horizontality. You will need to wait until the solution begins to dry.

- Another layer is applied on top of the dried mixture. After which the first row of brick screed is laid.

- The mortar is applied to the end of the first brick, after which it is laid by pressing down. It is tapped and leveled according to the string; the remaining mixture will need to be removed immediately before it has time to dry.

- If an opening for a door is planned in the partition, it will need to be positioned first. The door frame is installed using spacers. The evenness of its location is checked and, if necessary, this parameter is adjusted.

- The brick is laid close to the box. To tie the partition together, special metal strips are used; they are folded and attached to the side surfaces between the bricks. Instead of strips, you can also use reinforcing rods.

- After laying the first row is completed, the brick is divided into 2 parts with a pick. One half is used to start the second row. The string that served as a guide is moved higher so that you can easily navigate. Laying the third row is carried out in the same way as the first. For more information about the process, watch this video:

Building any kind of partition between the steam room and the sink is a rather labor-intensive procedure.

Not every beginner will be able to do this kind of work on their own.

But, as a result, this will ensure a high level of comfort in the bathhouse, which is why the construction of such elements has recently become popular.

Also useful for repairs:

- How to knit a hat and snood with braids

- Diamond cutting wheels for metal

- DIY flowers in a dhow

Attaching drywall to the finished frame

Installing drywall on a wooden frame is extremely simple. The gypsum boards are fastened to the finished sheathing using self-tapping screws with a conical head, which is recessed flush with the surface. The fastener pitch is 0.3 m.

On sheets without a factory chamfer, a bevel is selected on the edges using a construction knife or power tool. The gap is cleaned of debris and dust and primed.

After the primer has dried, the gap between the sheets is filled with putty, and reinforcing tape is pressed into the joint with a spatula.

Reinforcement of drywall seams

Dried joints are cleaned with sandpaper, cleaned of dust and the entire surface is re-primed. A thin layer of putty is applied over the primer layer and leveled. The dried layer is rubbed with sandpaper and the dust is removed.

The master's work is afraid

Do-it-yourself installation of either a wooden or a metal frame is carried out according to a similar scheme. Today, metal profiles remain more preferable. Note! When using wood for lathing, it must be treated in advance with special solutions that will protect the beams and slats from the adverse effects of temperature and air, as well as the appearance of insects in them. The process of assembling a lathing from a metal profile is as follows:

- assembly of support profiles. You need to start from the floor so that all other profiles are oriented along it;

- Next, we install them strictly along the line of the previously applied markings, after which the installed profiles must be checked according to the building level. This will determine how smooth the wall sheathing will be;

- We fasten everything with dowels. In this situation, it is necessary to fasten the profile every 25 cm;

- Next, we install profiles along the entire wall. They must also be aligned using a level and be in the same plane;

Intermediate frame

- After this, we proceed to the installation of transverse jumpers made from rack profiles. The step of their installation is determined by the degree of loading of the wall structure. The more weight it will have to withstand, the more often it will be necessary to install crossbars.

Note! To make the structure more durable and rigid, it is necessary to use mounting hangers.

Once the frame is ready, you can begin covering it with plasterboard sheets.

Finishing

Before the final treatment, the plasterboard is primed again.

Primer of drywall before finishing

This composition is chosen for the finishing material:

- surfaces to be painted or colored plaster are primed with a tinted product corresponding to the type of paint or decorative composition;

- under the wallpaper primer - glue diluted in a certain proportion;

- When facing with slab materials, an adhesion-enhancing primer is needed.

The primer is applied 2 times, and the dry surface is treated with the final product.

Photo selection of wooden frame designs for attaching drywall

Installation features

To lath walls with metal profiles correctly, you need to follow some tips. We present to your attention a small selection of the most important recommendations, the implementation of which will help you avoid the most common mistakes of beginners:

Wood processing

- avoid contact of self-tapping screws and screws with wiring elements that are usually routed along the walls;

- in humid climates, to create a frame it is necessary to use only metal elements, as well as a moisture-resistant type of plasterboard sheets. If you intend to use wood for sheathing, be sure to treat it with several layers of a special protective solution, which will protect against the negative effects of moisture and repel wood insects;

- start installing profiles from the floor and along the entire perimeter of the walls;

- when living in a climate characterized by temperature changes, snowy winters and hot summers, it is advisable to install insulating materials in the frame;

- the use of untreated wooden slats is highly undesirable. They must first be sanded and the surface made smooth. This is also why many people prefer to use metal elements to create wall sheathing.

Guided by these recommendations, you can frame any room without the slightest problem and get perfectly smooth walls. In addition, you can create complex wall devices that will include niches or shelves made of plasterboard. When creating a frame, remember that all the strength and beauty of the final repair depends on it.

Requirements for lumber used to create sheathing

The timber must be checked carefully. It may be a faint yellow or light brown color with no black or blue spots. Each part must have the correct geometric dimensions without chips, large cracks or deviations in straightness.

For construction and finishing work, it is recommended to use wood with a moisture content of about 15%. It is impossible to check this on your own, so when selecting material you just need to make sure by touching your hand that it is not wet. Before installation, it is advisable to keep the bars in the room where they will be installed for several days.

To protect against biological decay, mold, wood beetles and rodents, wood is treated with antiseptic compounds. You can use ready-made mixtures for interior work or prepare a 4% sodium fluoride solution yourself by stirring it in hot water. The antiseptic is applied to the bars with a brush in several passes and the material is allowed to dry thoroughly.