One unpleasant feature when working with wood is the presence of a large amount of shavings, sawdust and finer wood dust. Accumulating in the workplace, they create unbearable working conditions. In addition to the fact that they interfere with technological operations, they are dangerous to health. To solve this problem, many complex and expensive machines are equipped with industrial vacuum cleaners. The presence of such an option significantly increases the price of the entire unit. However, this problem can be solved in a budgetary way. To do this, you need to assemble the chip pump yourself. Such a system does not require complex equipment, and can solve the problem of chip collection quite effectively.

How does the chip pump work?

A flexible hose, preferably corrugated, of small diameter, is connected to the mechanism. The smaller the cross-section of the hose, the higher the speed of the sucked air, which means the quality of cleaning will be better. Along with large chips, small particles several microns in size will be removed from the room.

The air in the device is discharged due to the rotation of an impeller connected to an electric motor.

Features of choice

If it seems to you that making a chip ejector yourself will be difficult, you can choose from existing models. When choosing a vacuum cleaner for removing sawdust and shavings, it is first important to decide what type of dirt you will be removing. If you usually work on metal, then you will need to think about purchasing or even creating a powerful stationary device.

But as a carpentry vacuum cleaner that will remove wood dust and shavings, small mobile units with long flexible hoses are usually used. In a large number of cases, the designs of hand-held woodworking tools already have connections for connecting a suction hose with a standard size of 3.4 cm, and this exactly corresponds to the size of a household vacuum cleaner hose.

Selection of material

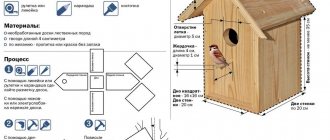

A hose, preferably with a fabric braid, from an old vacuum cleaner, is suitable for removing air with debris. You will need a plastic sewer pipe D = 50 mm and a length of 150 mm, a plastic corner bend of 45 degrees and a length of 200 mm, a plastic bucket from 10 to 25 liters with a lid, and a second bucket can be purchased in smaller sizes (5 - 10 liters).

You will also need 20 mm thick plywood, screws and sealant.

How to make it yourself

An industrial type vacuum cleaner for removing chips and dust consists of several main parts, namely:

- Air duct.

- Vacuum pump.

- Working nozzle.

- Cyclone filter.

If you set yourself the goal of making a full-fledged chip pump with your own hands, then we suggest considering which units and components can be used ready-made, and which ones you will need to make yourself from scrap materials.

Pump

If you need to make a productive and powerful vacuum cleaner in order to remove metal shavings in a metalworking room, then you will need to find or make your own centrifugal pump.

If you are careful, you can make the snail assembly and centrifugal wheel yourself out of plywood with your own hands, and also use metal corners as an addition. For the pump drive, an electric motor should be used, the power of which will be from 1500 to 2500 W.

Please note that if you are planning work in a carpentry workshop, then it will be easiest to use the simplest household vacuum cleaner as a pump. Given that shavings are much heavier than household dust, you should choose the most powerful vacuum cleaner model available.

Air ducts

If you are designing a high-performance chip extractor for your workshop, you must be very careful in choosing the materials and sizes from which the air connections will be made.

The larger the air outlet size, the less power loss will occur. In a small pipe, not only will the air flow be greatly inhibited, but also, after a while, “plugs” may begin to form from accumulations of small chips, as well as dust residues from the wood.

At the moment, you can find ready-made corrugated hoses on sale for creating air ducts of different diameters. A spiral-type frame, which is made of spring steel, will provide such air ducts with a sufficient level of strength. When assembling air ducts from such a corrugated hose, you should pay attention to how to seal the joints and connections. The slightest cracks can cause the device to begin to suck in air and reduce the efficiency of the entire device as a whole.

It will be quite convenient to use polypropylene sewer pipes, which already have couplings and cuffs, for assembling air ducts. This will ensure ease of disassembly and assembly, while ensuring a tight and reliable connection. If you are constructing a carpentry chip extractor with your own hands according to a drawing based on a home vacuum cleaner, then you can use polypropylene pipes for the air duct, as well as pipes with a diameter of 3.2 and 4 cm. These are the most popular sizes, and a wide range of fittings makes it possible to assemble ingenious designs without any problems. Polypropylene parts are also useful for making a filter.

Cyclone filter

The most complex and quite interesting unit in the design of an industrial chip ejector. Naturally, you can purchase a ready-made cyclone. Cyclone-type air cleaning units are manufactured industrially in a variety of sizes and with varying degrees of productivity. This ensures a high level of cleaning efficiency as well as ease of maintenance.

But it will be much more interesting and also cheaper to assemble the unit yourself. It’s easy to find ready-made drawings online, as well as technologies for assembling a cyclone filter from scrap materials. But the design and dimensions of the cyclone filter will largely depend on what exactly you have available. In order to remove all accumulated waste from time to time, the filter must be equipped with a removable lid or hatch, and it must fit tightly and prevent even the slightest air leak.

The following can be used as a working container:

- Homemade container.

- A large plastic bucket for paint and varnish materials.

- A plastic barrel with a capacity of several tens of liters.

Please note that you can assemble a container for collecting dust and shavings with your own hands, for example, from plywood. When making a container from wood, the joints must be carefully coated with sealant and the individual parts must be firmly connected.

But the most difficult thing will be to provide a hole in the design for waste removal, which must close tightly. You can use the cut-out top of a paint can, for example, because the lid is easy to open but still provides a tight seal to empty the trash. It will be convenient to use a bucket that closes tightly for the filter housing. Putties, paints, and building mixtures are usually sold in such containers. From a bucket with a capacity of about 20 liters you can make a mobile and compact filter for a carpentry chip extractor based on a conventional vacuum cleaner.

The best cyclone-type filters for the workshop are made from a plastic barrel with a tightly screwed lid. Such barrels can have a capacity of 20-150 liters, but it is worth keeping in mind that a square-shaped barrel will not work, only a round one is required. The key part of the cyclone will be a device for suction from the container and supplying a dirty air stream from the nozzle. Air suction is performed vertically along the axis of the filter, and the suction pipe can be attached directly to the center of the lid of the bucket or barrel. Just take into account the fact that ideal results will be obtained if you suck out the air not from under the lid itself, but at a height of ½ to 2/3 of the container size. For this reason, not a short pipe will pass through the lid, but a tube of the required length.

The dirty air flow is supplied from above, but horizontally. And this is where the trick comes in. In order for the air flow to swirl along the wall of the cyclone, the inlet pipe must be directed along the wall.

The easiest way to organize such a flow is to install a corner as an inlet pipe. The air that enters the nozzle will turn the flow 90 degrees and be directed along the wall of the cyclone, but in the corner nozzle the air flow will slow down greatly, and in addition, chips and dust will accumulate in the corner. A high-quality solution would be to install the inlet pipe in the form of a straight tube, which is mounted obliquely as close as possible to the wall of the tank.

It will allow contaminants to get inside the cyclone without hindrance and accelerate perfectly along the wall. This will create a powerful spiral flow. The connections must be rigid, and when the chip ejector is operating, the cyclone body will vibrate noticeably. Be sure to ensure excellent tightness, and to do this, use elastic sealants, which are used for installing plumbing fixtures and windows.

Working attachment

How to make a chip ejector for a metal-cutting machine? It is possible to assemble a rigid air duct structure, which is fixed to the machine frame. If the device is used for a carpentry workshop, then the hose of the working nozzle must be flexible and long, and ordinary hoses from a household vacuum cleaner are ideal for this.

It is especially convenient that the hoses from the vacuum cleaner fit perfectly together, and also the “crevice” nozzle for the hose that comes with a household vacuum cleaner is perfect for sucking out chips and dust. Without a nozzle, a household hose is usually tightly connected to the nozzle of a hand-held electric jigsaw or belt sander.

Cyclone assembly

The design of the chip ejector must include the use of a cyclone filter.

Cyclone assembly:

- Installation of a ring for fixation;

- Side pipe fastening;

- Assembling a figured insert;

- Making a cyclone.

Design options and operating principle

A classic cyclone type chip ejector is a vertically mounted cylinder, smoothly tapered at the bottom. The vacuum created by the fan draws polluted air into the housing. Spinning and falling under the influence of centrifugal force, wood waste falls into the lower part of the cyclone chip suction machine, where a storage hopper is installed.

To collect dispersed dust suspension, a filter unit of bag filters is installed, capable of periodic regeneration by shaking.

Offers various models of chip ejectors. From the smallest - weighing only 8 kg, to a professional installation weighing 76 kg, which allows you to simultaneously connect four air ducts.

In addition to the main operating mode, it is possible to collect chips from the floor. Anchor chip ejectors are produced under the Corvette brand and are distinguished by the numbers added to the name. They are equipped with two types of bags – filtering and dust collection.

“Jet” is a brand under which a line of chip ejectors similar to the “Corvette” is produced. Often, the consumer has to make a choice between these two suppliers. According to some of them, Jet chip pumps are distinguished only by their color and higher price, but experts note the longer service life of this brand.

When paying attention to the design, we must not forget about the main functional characteristics: flow power and performance. Fans of German quality can pay attention to chip ejectors

The company, founded in 1924, is a leader in the introduction of new technologies and materials into production

Thus, some design elements of Metabo chip ejectors are made using ABS plastic: volute body, fan, impeller. This made it possible to reduce the weight of the device, and most importantly - to reduce the noise level at maximum engine speeds.

The company, founded in 1924, is a leader in introducing new technologies and materials into production. Thus, some design elements of Metabo chip ejectors are made using ABS plastic: volute body, fan, impeller. This made it possible to reduce the weight of the device, and most importantly - to reduce the noise level at maximum engine speeds.

Admirers of German quality can pay attention to chip ejectors. The company, founded in 1924, is a leader in the introduction of new technologies and materials into production

Making a ring and insert

- Cut off the side of a small plastic bucket.

- Having placed the container on the plywood, you need to circle its bottom and determine the center of the resulting circle. To find the center, it is enough to draw 2 perpendiculars to the drawn tangents.

- Another circle is drawn 30 mm larger than the first.

- Using a jigsaw, cut out a ring along the drawn circles.

Types of manufactured chip ejectors

You can buy three types of chip ejectors in the store:

- Household;

- Universal;

- Professional.

They differ only in the cyclic rotation system and power. For home use, household and universal chip extractors are more suitable; they cost less compared to professional devices, but at the same time they can cope with a small amount of work.

However, workshops providing forest processing services require the purchase of professional equipment, since they can be operated for a long period of time without breakdowns.

Ring retainer installation steps

The ring is attached to the cut out side of the plastic container.

- Screw the side using self-tapping screws.

- To prevent the plywood from bursting from the screws, you need to drill holes at the fastening points of a smaller diameter than the thickness of the screws.

- On the lid of a large container, a circle is marked equal to the diameter of the bottom of the container itself.

- Cut out the resulting circle, securing it to the side of a small container with screws.

Design features of home chip vacuum cleaners

Even an amateur without technical education can make a functional chip ejector in a carpentry workshop. The first thing to note in such devices is the presence of a motor operating from an electrical network of 220 volts. It is not advisable to purchase three-phase motors, since many difficulties arise with their connection under normal conditions.

It is better to purchase a fan with a powerful impeller. It provides good spiral turbulence of the intake air with chips.

Preparatory stage

A self-made chip ejector will cost several times less than analogues in the store. Some parts for assembly can be found in a workshop or garage, but some of them will still have to be purchased. To quickly produce equipment you need to:

- Draw up a work plan. It is necessary to clearly know what elements will be required during assembly;

- Purchase an electric motor, check its performance and ability to connect to the network in a workshop;

- Select parts that are impossible to make yourself;

- Frame. It can be made of wood, but many use durable plastic tanks with a lid.

When preparing the necessary parts, it will take 2-3 hours to assemble the device.

Installation of the pipe

Before installation, you need to make a hole in the bottom (not in the center) of a small container, and insert a 45-degree elbow into it. The outlet is attached with self-tapping screws and sealant to ensure tightness and strength of the joints.

Why do you need a dust removal system for CNC machines?

Health Hazard

Various dust particles pose a risk to human health. Dust particles suspended in the air can land on our skin, or you can inhale them. When dust from certain materials, such as wood, settles on your skin or eyes, it can cause irritation, itching, or an allergic reaction in the area. Some common skin problems caused by CNC dust include acne, rashes, redness, itching, dryness and flaking.

Some materials can be toxic, and milling produces fine dust particles that, if inhaled, can cause short- and long-term breathing problems. Additionally, if you have breathing problems, inhaling dust from CNC routers can make those problems worse. Therefore, to prevent such occurrences, you should use a dust collection system or wear masks when using your CNC router.

| Wood | Health effects |

| Alder (common, black, red) | Dermatitis (black alder), decreased lung function (red alder) |

| Beech | Beech bark lichen dermatitis, rhinitis, asthma, nasal cancer |

| Birch | Irritant dermatitis |

| Cedar (western red) | Asthma, contact dermatitis, allergic reactions, decreased lung function, eye irritation, rhinitis |

| Fir (grand, balsam, silver, alpine) | Skin irritation, dermatitis, rhinitis, asthma |

| Red tree | Dermatitis, allergic reactions |

| Maple | Rhinitis, asthma, maple bark stripper disease |

| Oak | Nose cancer |

| Pine (white, stick, jack) | Skin irritation, contact dermatitis, rhinitis, asthma |

| Poplar | Contact dermatitis, allergic reactions |

| Rosewood | Eczema, allergic contact dermatitis |

| Spruce | Skin irritation, decreased lung function |

| Teak | Toxic, dermatitis, allergic reaction |

| Walnut (black) | Skin irritation, rhinitis |

| Yew | Skin irritation, dermatitis |

Possible health effects of some common forests

Fire Danger

Concentrated clouds of dust suspended in the air are highly flammable and explosive. The particles are small enough to ignite spontaneously, and the available air causes them to burn instantly. This could cause serious injury to you or anyone working in the area. The dust collection system will prevent such cases from occurring.

Top outlet mounting

- The entries are drilled in the center of the bottom of the small bucket.

- The plastic pipe is attached to a sheet of plywood with a prepared hole equal to the thickness of the pipe.

- The structure is screwed from below with four screws.

- Fill all formed joints with sealant. In addition to tightness, it gives the assembly additional strength.

The insert is attached to the outer wall of the filter using self-tapping screws.

Design options and operating principle

A classic cyclone type chip ejector is a vertically mounted cylinder, smoothly tapered at the bottom. The vacuum created by the fan draws polluted air into the housing. Spinning and falling under the influence of centrifugal force, wood waste falls into the lower part of the cyclone chip suction machine, where a storage hopper is installed.

To collect dispersed dust suspension, a filter unit of bag filters is installed, capable of periodic regeneration by shaking.

Offers various models of chip ejectors. From the smallest - weighing only 8 kg, to a professional installation weighing 76 kg, which allows you to simultaneously connect four air ducts.

In addition to the main operating mode, it is possible to collect chips from the floor. Anchor chip ejectors are produced under the Corvette brand and are distinguished by the numbers added to the name. They are equipped with two types of bags – filtering and dust collection.

“Jet” is a brand under which a line of chip ejectors similar to the “Corvette” is produced. Often, the consumer has to make a choice between these two suppliers. According to some of them, Jet chip pumps are distinguished only by their color and higher price, but experts note the longer service life of this brand.

When paying attention to the design, we must not forget about the main functional characteristics: flow power and performance. Admirers of German quality can pay attention to chip ejectors. The company, founded in 1924, is a leader in the introduction of new technologies and materials into production

Thus, some design elements of Metabo chip ejectors are made using ABS plastic: volute body, fan, impeller. This made it possible to reduce the weight of the device, and most importantly - to reduce the noise level at maximum engine speeds.

The company, founded in 1924, is a leader in introducing new technologies and materials into production. Thus, some design elements of Metabo chip ejectors are made using ABS plastic: volute body, fan, impeller. This made it possible to reduce the weight of the device, and most importantly - to reduce the noise level at maximum engine speeds.

Admirers of German quality can pay attention to chip ejectors. The company, founded in 1924, is a leader in introducing new technologies and materials into production. Thus, some design elements of Metabo chip ejectors are made using ABS plastic: volute body, fan, impeller

This made it possible to reduce the weight of the device, and most importantly - to reduce the noise level at maximum engine speeds.

Thus, some design elements of Metabo chip ejectors are made using ABS plastic: volute body, fan, impeller. This made it possible to reduce the weight of the device, and most importantly, to reduce the noise level at maximum engine speeds.

How does a cyclone chip pump work?

The air purified by the cyclone along with the garbage from the room is thrown outside. The filter involves the use of an electric motor with a power of 3.5 kW.

It sets into rotation the impeller, which can withstand a fairly large load and create the necessary air vacuum. Filtration in such a chip ejector is carried out in several stages.

Large debris, after passing through the filter, is collected in a special bag. The installation housing must be sealed. To reduce noise, the housing can be covered with absorbent material.

It is possible to make such a device yourself.

Device Features

As a rule, the air stream should be cleared of debris and passed through a container of water or a cloth filter. This will be quite enough to retain dust and small household debris. The vacuum cleaner for sawdust and shavings has a slightly different design.

It does not have a fabric filter, because it will only create unnecessary resistance to air flow.

Wood shavings, sawdust and dust should be removed from the air ceiling into a centrifugal force apparatus, namely a cyclone. In most large industries, industrial-type chip vacuum cleaners are used to suck out large sawdust and shavings and the working area of a wood processing machine. These are large devices with incredible power, although they are designed in the same way as small carpentry-type vacuum cleaners.

Filter from plastic buckets

To make a garbage disposal, you will need a cutting tool, a tool for drilling, surface treatment, a heat gun, a pencil, a ruler, and a knife.

The material you can use is laminated chipboard, a plastic thirty-liter tank, a PVC pipe, hot melt adhesive, silicone sealant, bolts, nuts, and screws. You will also need a vacuum cleaner with a hose.

Cloth dust bag

How to make a filter for a vacuum cleaner with your own hands from the materials you have in your farmstead? A thick bag made of any fabric, ready-made for shoes or specially sewn, will come in handy.

A piece of PCB, suitable in size for the existing vacuum cleaner, is needed to attach the bag to it. To hold some of the debris that gets into the bag, you also need a clamp that will secure the entire filter.

Note!

DIY induction heater - instructions on how to make a simple and powerful heaterDo-it-yourself sound amplifier: selection of materials and tools for making at home + step-by-step instructions for creating and assembling yourself

- Do-it-yourself wind generator: step-by-step instructions for making a device at home, choosing materials and type of construction

A hole is made in the PCB to match the diameter of the outlet valve. The hole in the bag is attached to the PCB, and a hole is cut at the opposite end of the fabric section to release the collected particles of larger debris. The fabric should be periodically removed and cleaned of fine dust.

Manufacturing procedure

- A partition is cut from a sheet of laminated chipboard to connect plastic containers.

- Grooves are cut on it for a tight connection with the edge of the bucket.

- A plate is cut to cover the cyclone filter.

- The jumper is attached to the buckets using sealant, then a hole is drilled that connects both vessels.

- The bottom of the container is cut out to create a cone.

- The assembled structure is tightened using clamps and left alone until the sealant dries.

- The recess on the hopper lid is filled with hot melt adhesive.

- Using a drill, you need to make a hole with a diameter of 50 mm. A 120 mm long pipe with sealant is installed into it.

- A PVC corner outlet is inserted into the side hole. It is secured with bolts and nuts.

The cover is put on the mechanism and the vacuum cleaner is connected. The connected hose can be wrapped with electrical tape for better tightness.

Difficulties that you may encounter during work

It is not difficult, as we have seen, to create a cyclone filter with your own hands, or even a homemade vacuum cleaner, if you have the necessary materials.

In some cases, it is recommended to take metal containers for collecting garbage, as they are considered more durable. If you have a vacuum cleaner with enormous power, the plastic bucket can “collapse,” so to speak. It is drawn inward due to the strong flow of intake air. This happens extremely rarely, but it is better to immediately provide for this option. It can be leveled, but the damage to the product will be obvious. So you always need to take into account the quality of the plastic and the power of the device. In the case of a traffic cone, this problem does not arise.

Cyclonic designs of household vacuum cleaners are considered one of the most successful technology options in terms of operating efficiency. The cyclone system is a relatively simple separation mechanism that makes it possible to effectively filter suspended particles present in the air stream.

Based on the theoretical principles of constructing such a system, it is quite possible to create a cyclone for a vacuum cleaner, acting as an additional tool - for example, a construction separator. Interested in the question, but don’t know how to make a simple cyclone yourself? We will help you realize your plans.

The article provides detailed information about the design of the cyclone separator, as well as step-by-step instructions for assembling it and connecting it to a vacuum cleaner. A description of all stages of the work process is accompanied by visual photographs.

Making a cyclone from a traffic cone

A very simple and quick way to make is to use a traffic cone.

- You need to cut off the bottom and top of the cone and, turning it over, place it in any container to accumulate waste.

- Make a round lid approximately equal to the top of the chip by drilling a 40 mm hole in it.

- Secure the corner bend into the opening made in the side wall with glue.

- Glue all connections with a heat gun for tightness and strength. The waste collector is connected to the vacuum cleaner through a corrugated hose.

The chip ejector can be made from a wide variety of available materials with your own hands.

Operating principle

The cyclone, as it may seem at first glance, was created even primitively. This is an ordinary large round container (barrel or bucket). The incoming air flow begins to enter the upper part of the container, and at the same time the air stream is directed horizontally, along the wall. Due to this, the flow begins to twist spirally. The centrifugal force begins to throw all solid particles of debris towards the wall, and they gradually begin to collect at the bottom of the container. Since the air is light, the purified flow gradually begins to calm down in the center of the round container.

The vacuum of the cyclone inside the housing is created by suction of air from the pipe, which is located exactly along the axis of the container. In this part of the cyclone, the air is already cleared of sawdust, dust and shavings, and for this reason can be sucked out using any pump of suitable capacity. Even a household vacuum cleaner is often used as a pump. The design of an industrial cyclone-based chip extractor usually uses a special pump. As a rule, pumps of a centrifugal type are used here, and it looks like a “squirrel wheel” with blades placed across it, instead of the most common spokes.

The wheel should be placed in a housing that is shaped like a snail. A centrifugal wheel driven by an electric motor begins to accelerate the air mass around the ring and strongly throws it out through the exhaust pipe, which is located on the outside of the pump. In addition, a vacuum appears in the center of the centrifugal wheel. The pump design is characterized by excellent performance and unpretentiousness.

Please note that such devices are capable of sucking out even very contaminated air, and this makes them even more valuable in the design of an industrial vacuum cleaner based on cyclone cleaning.

Photo of a homemade chip sucker

Using other containers

Instead of a plastic waste collection barrel, you can knock down a box made of plywood, particleboard or wooden planks. The principle of connecting to pipes and a vacuum cleaner remains the same as when using a finished product.

It would be even easier to assemble a cyclone for a vacuum cleaner with your own hands from a bucket, metal or plastic, with a lid. If the volume of garbage is small, then such a container is enough for work.

But the smaller the area intended for the accumulation of dust and waste from construction or production, the more often it will have to be emptied.

What are they?

Dust fans belong to the group of radial or centrifugal devices. They are capable of creating sufficient pressure to move mass through the duct system. Centrifugal designs work equally well for both discharge and suction, which increases their capabilities, allowing the direction of flow to be changed if necessary.

This distinguishes them from axial fans, which are capable of high performance, but do not have the ability to provide high pressure. The air flow from axial structures cannot overcome the aerodynamic resistance of the air ducts, while simultaneously moving certain masses of material.

Radial fans vary in the amount of pressure they create. High-pressure dust fans for sawdust or shavings are needed to work on long and branched air duct systems. Medium and low pressure fans are used in appropriate conditions and are selected based on calculated data.

Expert opinion

Online ventilation store "Runicom"

The difference between dust fans and other centrifugal devices is the design of the impeller . Most samples have 16, 24 or more blades, but on dust fans there are much fewer - usually 5, 6 or 7, on larger numbers there may be 9.

The best cyclone vacuum cleaners according to consumer reviews

When choosing models equipped with a cyclone, you should pay attention not only to the technical characteristics, but also read reviews from real customers, which will help identify the strengths or weaknesses of a particular model. The ranking of the best samples includes household and industrial devices

Household vacuum cleaners with cyclone dust collector

The best models for home use, which do not have a dust collection bag and are equipped with a cyclone, are considered to be products from Dyson, which is the founder of this type of device. One of the best models can be considered the new Dyson Cinetic Big Ball Animal Pro 2. This is a vacuum cleaner that has a number of unique features:

Dyson Cinetic technology, which captures the smallest particles, which is important for people suffering from allergies. At the same time, after cleaning, no additional washing or replacement of filter elements is required; Ball system, which ensures the stability of the vacuum cleaner and increases its maneuverability

Even if accidentally tipped over, the device returns to its correct position; Musclehead brush, which is a turbo head with carbon fiber bristles.

Cinetic technology allows you to achieve constant stability of the vacuum cleaner during operation

The only drawback of the model can be considered its high cost, which is 39,000 rubles. But such a pricing policy is normal for a company that positions its products as products of the highest quality.

Review of Dyson Cinetic Big Ball Animal Pro 2

More details on Otzovik: https://otzovik.com/review_6463819.html

Dyson Cinetic Big Ball Animal Pro 2

Construction vacuum cleaners with cyclone filter

One of the best industrial-type models, according to professionals, is the Ghibli Power WD 80.2 I model. This is a device that is designed for cleaning class M dust over large areas. Its features include the presence of a larger tank (80 l). There are also two turbines inside the device, which together create a power of 22.5 kPa.

Ghibli Power WD 80.2 I – device with 80 liter stainless steel tank

Among the advantages, it should be noted the presence of a reliable stainless steel case, a drainage hole for draining dirt, a long power cord (10 m), three replaceable nozzles, and not the highest noise level for similar models. Among the disadvantages, users highlight the limited actual volume of liquid garbage (56 l) and the optional ability to collect dry garbage. The cost of the device is 34,000 rubles.

Cyclone filters are sold separately, making them easy to replace if necessary.

Adviсe

First of all, you need to know some of the intricacies of labeling. For example, fan No. 6.3 has an impeller diameter of 63 cm rather than 60 cm.

The most common fan model for small and medium-sized workshops is considered to be VRP 115-45 No. 6.3 or its analogues . At the same time, it should not be used without preliminary calculations, since operating conditions and the length of air ducts (sleeves) can significantly change the requirements for the fan.

Expert opinion

Online ventilation store "Runicom"

Dust installations experience strong vibration . The reason for this lies in the composition of the flow - the presence of a large amount of solid particles creates significant loads on the hoses, causing vibration. This forces you to constantly monitor the condition of the fan housing. Sooner or later, metal fatigue appears and cracks appear. If you don't touch them, the case may simply tear in half. The solution to the problem is welding along the fault line , but this measure is short-lived. The metal at the welding site is stressed, vibration loads quickly form a new crack, so after repair the body must be monitored even more carefully. If the problem cannot be resolved, the fan will need to be replaced.

Vacuum cleaner for workshop

The process of mechanical processing of wooden workpieces is always accompanied by the release of dust or the scattering of shavings and sawdust. Modern power tools provide the ability to connect any installations for the collection and disposal of wood waste, but purchasing them for household needs is not always justified. At the home level, a homemade device successfully copes with the problem of dust removal. Let us consider in detail the procedure for making a vacuum cleaner for the workshop.

Required materials and tools

The basis for the project is an old household vacuum cleaner, from which the following components are used: •Motor part; •Power regulator; •Power supply wire; •Suction hose; •Attachments.

For the homemade body, select a polyethylene barrel with a capacity of 50–80 liters, always with a fixed lid. You will also need: •A piece of plastic sewer pipe with a diameter of 50 mm; •Plywood 5–10 mm thick; •M6 bolts and nuts – 14 pieces each; •Strip of galvanized sheet; •Air filter from a minibus; •220 Volt switch; •Threaded rod with washers and nuts; •Construction sealant; •Sandpaper; •Glue rods; •Drain corrugated hose for washing machine; •Electrical installation corrugation HDPE 32.

Docking units are made of plastic tubes and fittings, selected depending on the size of the pipes on the tools and the diameters of the vacuum cleaner intake hoses. List of tools used: • Glue gun; •Drill; • Locksmith keys; •Screwdrivers; •Pliers; •Electric jigsaw; •Sharp knife; •Files; •Sealant gun.

The process of making a vacuum cleaner for a workshop

Stepping back approximately 100 mm from the top, mark a hole on the wall of the barrel for the inlet pipe and drill it using a drill. Then use a knife to give the hole an oval shape so that the inner end of the pipe is placed close to the wall and points down at a slight angle. Degrease the surfaces to be joined and, using a glue gun, fix the pipe in place.

Using the same “hot” method, an adapter for the suction hose is attached to the outside of the pipe.

Using a jigsaw, cut out two circles from plywood with a diameter slightly smaller than that of the barrel lid. First, two holes are made in the blanks for bolts and the parts are secured on both sides of the cover. Next, drill the remaining holes, remove the circles and remove the burrs with sandpaper. Apply sealant around the perimeter of the workpieces, place the parts on the lid and fully install the fasteners. A hole is made for the pin in the center of the plywood circles, and a little to the side for the air intake of the motor block.

Remove the metal mesh from the air filter with pliers, otherwise it will become clogged with sawdust and interfere with cleaning the vacuum cleaner. One end of the cylinder is covered with a plywood plug.

The prepared filter element is secured to the stud with a wing nut.

The motor part, as a rule, has a round shape. Therefore, for ease of installation, the plastic parts in which the motor was located are cut out from the body of the old vacuum cleaner. Thanks to them, to secure the unit to the barrel lid, you only need one clamp, made from a strip of tin.

A switch and power regulator are placed next to the engine, placing the latter in a suitable box. All that remains is to connect the elements together with wires and connect the cable with the plug. After making sure that the connections are correct and that there are no exposed contacts, apply power and check the operation of the device.

The standard suction hose of a household vacuum cleaner is too short; it is extended with a corrugated tube for laying wiring or another similar product.

Manufacturing of nozzles and adapters

Cleanliness in the workshop begins with the workbench. To clean the workplace, use a standard brush that comes with the household appliance.

The nozzle is connected using a rubber adapter cut from a tube of appropriate caliber, for example, from a pipe of a car’s cooling system.

One of the most littered power tools is the power planer. The outlet fitting of the tool is large enough; most likely, the vacuum cleaner hose will connect without problems.

For a manual surface grinder, you will need to make an adapter that is soldered to the dust bag clamp.

In this case, a thinner hose from the washing machine drain and the ability to electronically reduce the suction power of the vacuum cleaner so that the body does not shrink will come in handy.

The same corrugation is suitable for suctioning chips from the working area of a manual router.

Using the selection method, the corresponding parts are also found for the pallet of the circular saw.

Subtleties of connecting a homemade cyclone

A self-assembled cyclone (filter for construction purposes) is connected for operation in a simple way.

The input (side) channel is connected by a corrugated flexible hose or other similar accessory to a working tool, for example, to the channel of an electric jigsaw.

The output channel (upper pipe) is connected directly to the input socket of the vacuum cleaner instead of the working nozzle.

Connection diagram - connecting a cyclone in pairs to a household vacuum cleaner and construction tools, the design of which supports the function of garbage suction

First, a vacuum cleaner is put into operation, then a construction tool is used for the necessary purposes. As a result, the action being performed, say, cutting a board with an electric jigsaw, takes place without releasing chips and fine dust into the environment.

The by-product of the operation is completely sent to the cyclone separator where it is properly filtered.

DIY enthusiasts can try to assemble a complete vacuum cleaner that can be used in the workshop or at home. Step-by-step instructions for making a practical unit are presented in this article.