Often when working with wood, it becomes necessary to drill holes of various diameters. For this purpose, there is a whole arsenal of devices, which, as a rule, are united under the general name of wood crowns. However, professionals divide them into several directions, for example, a 110 mm wood crown can be not only a crown as such, but also a crown mill, and to reduce these errors, we will try to understand the assortment.

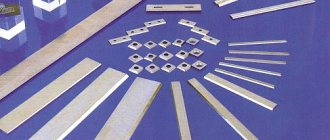

Photos of classic wood crowns.

Most common devices

All devices of this type are made of durable tool steel. The denser the array, the stronger the cutting edge should be. Any tool, in addition to the cutting edge, must have a working part and a clamping shank.

Twist drills

This is a classic type of tool, almost everyone is familiar with them; it is this type that every person means by the concept of a drill. The model range for wood processing here ranges from 3 to 52 mm.

Interestingly, products with a diameter of up to 10 mm are made smooth. But everything that goes higher often has a hexagonal clamping shank. It is necessary because the load during drilling increases many times and the tool is able to rotate in the chuck.

Standard twist drills.

Important: the entire model range, except for the crown cutter, designed for working with wood can be distinguished by the presence of a sharp guide shank. It is the first to enter the array and prevents the tool from slipping or deviating to the side.

When working with such attachments, the number of revolutions set on the drill is of great importance; if these parameters are neglected, then in the best case, you will not be able to drill a hole, in the worst case, you can “burn” the drill at high speeds when overheated or even break it.

- So small drills, the diameter of which does not exceed 14 mm, work best on soft wood at 1800 rpm. If you have to work with hard wood, then the number of revolutions is reduced to 750.

- The average diameter of the tool is considered to be from 16 mm to 25 mm. For this direction, experts recommend setting 1500 rpm on soft wood. Hard material is drilled at 500 rpm.

- From the upper threshold of the medium diameter to the maximum dimensions of 52 mm, you should work at 500 rpm on soft material and at 250 rpm on hard material.

The length of the working surface of the drill also varies. Here everything directly depends on the diameter of the tool; the thicker the drill, the longer it can be. The minimum length is considered to be 80 mm, the maximum is limited to 600 mm.

Tool for making large diameter holes.

In addition, it would be useful to maintain a reasonable ratio between the diameter of the cutting surface, the size of the drill and the power of the drill itself. So, for example, a fifty-millimeter drill with a length of 60 cm will weigh about 3 kg and not every drill is capable of turning it even at idle.

Feather drills

This is a rather specific tool; the sizes of holes that can be made with their help range from 10 to 55 mm. Their main advantage is their simplicity of design and low cost. The price for pen models is 10 times lower than for twist drills.

But they have a serious disadvantage. It is quite problematic to drill a deep hole with feather drills, this is due to the fact that there is no mechanism for removing chips. Essentially, it is a flat, multi-directionally sharpened knife with a guide spike in the middle.

All models of this type have a hexagonal shank, this is caused by heavy load during operation.

Most often, such a tool is used to work with thin boards, plywood, as well as chipboard, USB or fiberboard.

- As for the number of revolutions, they are higher here than in spiral versions. Thus, feather nozzles with a diameter of up to 25 mm operate at 2000 rpm on soft wood. Hard material is processed at 1500 rpm.

- Accordingly, wide nozzles 30 - 55 mm, drill on soft material at 1500 rpm. For hard rocks, no more than 1000 rpm should be set.

Adapter for deep holes.

Important: the length of a standard pen nozzle does not exceed 150 mm. If there is a need to increase the length, adapters are used that can extend up to 450 mm.

Forstner drills

It is these attachments that are often confused with classic crowns. Their spectrum of action is quite wide. With this nozzle you can easily make a blind hole of a perfectly regular shape with a flat bottom. Due to this feature, they are often used in furniture production.

In addition, if extensions are inserted, the forstner drill bit can be used as wood core bits for deep drilling. But the maximum diameter here does not exceed 50 mm.

In these nozzles there is also a dependence of the diameter on the number of revolutions.

| Nozzle diameter | Number of turns on soft wood | Number of turns on hardwood |

| 10 - 15 mm | 2400 rpm | 500 rpm |

| 20 - 25 mm | 1500 rpm | 500 rpm |

| 30 - 50 mm | 1000 rpm | 250 rpm |

Wood crowns

A classic crown for drilling wood is an improvised cup, along the perimeter of which there is a cutting toothed surface. It is mounted on a special chuck that has a separate drill in the center. For creating wide holes in sheets or boards up to 60 mm thick with your own hands, these devices are ideal.

Advice: although the range of such crowns is quite wide, experts say that an inexperienced person can drill by weight with a hand drill with a cup no larger than 100 mm. Already a diameter of 120 mm or 127 mm is better to clamp into a drilling machine.

Wood crowns with a large diameter of 150 mm are rarely used by amateurs; these attachments are closer to professional ones, since working with such a tool requires fairly powerful equipment, and not everyone can afford it.

A special niche among such tools is occupied by a wood crown cutter. The price of these nozzles is serious, but with their help you can easily make holes up to 150 mm deep. The only drawback of this tool is the inability to make blind holes.

How to properly drill a concrete wall with a drill. Part 1 of 2: Preparing for work

- 1

Buy or rent an impact drill. It is easier to drill holes in concrete with an impact drill or hammer drill (in case of large work). X Source of information These tools will allow you to crush concrete with reciprocating blows of the drill and extract the resulting crumbs by rotating it. Doing this type of work with a conventional drill will be slow and difficult, since concrete does not drill as easily as wood or metal. For any job that will involve more than drilling a few holes in decorative (rather than structural) concrete surfaces, such as today's softer stone chip kitchen countertops, don't skimp on paying a little more to rent a hammer. X Source of information

- When purchasing a tool, it is usually wise to pay more for a more powerful hammer drill (with an impact force of at least 7-10 J) from a well-known brand. X Source of Information Other useful features to consider include adjustable rotation speed, adjustable drilling depth, ease of grip, and a second handle.

2

Learn the tool. Read the owner's manual and memorize the functions of all buttons and switches on the instrument. You should have a good understanding of how to handle the tool before moving on to the next step.

- Follow safety precautions. This includes wearing safety glasses to prevent concrete chips from getting into your eyes, using earplugs to protect your hearing, and thick work gloves to protect your hands from increased friction and hot drill bits. For long periods of work that generate a lot of dust, it is also recommended to wear a respirator.

3

Insert a high-quality concrete drill bit into the tool. Carbide tipped concrete drill bits (or “percussion bits” as the packaging may indicate) are specifically designed for impact drills and can withstand the stress of impact drilling into strong concrete. The length of the fluted drill bit should be no less than the depth of the hole you are going to drill, as these flutes are important for removing generated dust from the hole. X Source of information

- For hammer drills, it is necessary to use special drills, or so-called drills, marked SDS or SDS-MAX (for drilling holes up to 1.5 cm in diameter) or punch drills (for holes with a diameter of 2 cm or more). X Source of information

- Reinforced concrete is much more difficult to drill if the depth of the hole must be greater than the depth of the steel reinforcement in the concrete. As soon as the concrete drill reaches the reinforcement, replace it with a metal drill. X Source of Information Slow down and stop periodically while working to prevent the drill from overheating.

4

Adjust the drilling depth. Some drills have the ability to adjust the drilling depth or a special limiter. Read the tool's user manual to learn how to use it. If your tool does not have a drill depth stop, measure and mark the required hole depth on the drill itself with a pencil or masking tape. If you are unsure about the depth of holes you need, follow the guidelines below. X Source of information

- Since concrete is a hard and dense material, holes 2.5 cm deep will be enough to attach screws to dowels in the wall for hanging light objects. Heavier items will require the use of longer screws with dowels or even anchors, the minimum fixing depth of which should be indicated on the packaging.

- Increase the hole depth you require by 5mm to allow room for any remaining dust generated during drilling. X Source of information This is not necessary if you are going to clean the hole from dust later (read about this below). X Source of information

- When working with hollow concrete blocks or thin concrete surfaces, be sure to read the instructions for the fasteners you are using. Some plastic anchors require strong support along their entire length and may simply fall out if inserted into a through hole on a thin wall.

5

Hold the drill correctly. Hold the drill in one hand like a pistol, with your index finger on the start button. If your drill has an extra handle, use your other hand to hold it for a more secure grip. Otherwise, simply grab the drill from below with your other hand, closer to the back of the body.

How to use a classic crown

Every good owner should have a set of wood crowns. Moreover, the price of the simplest models for amateur use often does not exceed $5. And this tool is used quite often, especially in private homes.

For professionals, of course, there is a disproportionately larger range of similar products, but, firstly, it costs more, and secondly, it is not a fact that you will need it.

- Initially, it will not be superfluous to understand what is actually included in the standard set. Often these are 10 - 12 running working attachments, ranging from a minimum diameter of 18 mm and ending with 50 mm, a maximum of 70 mm. There must be a central guide drill; the diameter may vary, but most often it is 6 mm. Plus 2 basic cartridges and a hexagon for fixing.

- The chuck itself, the design is not complicated, a drill is inserted into it in the center and clamped with a fixing bolt using the hexagon included in the kit. The cutting cup is inserted from the reverse side and is also secured with a clamping nut.

- The hole on the cup into which the cartridge is inserted has an irregular shape so that the nozzle does not rotate. You need to tighten the nut firmly, as a large load is placed on the crown, and it can become loose.

- After the drill and the cutting attachment itself are securely fixed in the chuck, you can insert the chuck into the drill or machine and start working. The instructions are practically no different from the usual drilling process; the only thing you should pay attention to is the strictly perpendicular position of the tool in relation to the plane being processed.

- As already mentioned, when cutting wood products, it is important to choose the correct number of revolutions. But in any case, the larger the diameter of the hole, the stronger the vibration of the tool will be, so it is advisable to use powerful drills with an additional holding handle.

Important: the sizes of wood crowns may vary, but all products have small holes or slots. On cups of large diameter they are located on top; on small nozzles the slots are made on the side. It is through them that the wooden plug can be pushed out at the end of the work.

Side slits on the cup.

The video in this article contains additional information on the topic.

Distinctive features

Regardless of what material the crown purchased from Leroy Merlin will be used for, it has a standard design like all the others. It consists of the following elements:

- cutting head;

- elongated cylindrical or ribbed shank;

- guide drill.

The kit can be supplemented with a hexagon for high-quality clamping of a core drill.

Manufacturers offer two design options for wood crowns for deep drilling:

- non-separable solid metal structure for making a hole of the same size, for example, wood diameter 120 mm

Structure of a non-separable drill

- a collapsible design, which consists of a holder with a shank, to which a cutting ring of the required diameter is attached; for all mounted crowns there is a table in the instructions for use.

A stacked hole saw consists of several removable links of different diameters

In the first option, a solid ring is used, and in the second, an open ring in the form of a split cylinder is used. Quick ring changes speed up any machining process. Each cutting element has special technological holes for removing chips. They are made in the form of circles or slots on the side surfaces of the cylinders for small diameter tools and additionally at the ends for large ones.

Some craftsmen independently make a wood crown in their workshops, using a thick-walled metal pipe of the selected diameter.

Conclusion

A classic wood bit of 68 mm with a cutting depth of up to 64 mm is considered by experts to be the maximum diameter that is suitable for standard drills up to 3000 rpm. Next, you need to use professional attachments such as a core cutter for wood.

Wood is good because it is easy to drill. And in stores you can now buy a huge number of drill bits that are suitable for creating holes and recesses of various sizes and configurations.

The drill is inserted into a special chuck, the cutting edge moves and forms a hole - this is the principle of operation of the tool. The design of different types of drills differs quite significantly from each other.

To increase functionality, you can use drill bits. They allow you to cut round holes of different diameters and work not only with wood, but also with plasterboard, plastic, and chipboards.

Crown structure

A standard crown consists of the following elements:

- Shank . Fastening for inserting equipment into the chuck of an electric tool.

- Centering drill . The main guide for creating holes.

- Cutting attachment . A cylindrical “blank” with a jagged end.

Core drills with countersinks allow you to deepen the outer edge so that the socket box does not protrude even a millimeter above the wall surface.

Manufacturers produce cutters of two design types:

- Collapsible . All elements can be removed and any of them replaced.

- Non-separable . If something breaks or wears off, just throw it away.

According to the type of fastening, cutter shanks are divided into: triangular , hexagonal , SDS Plus and SDS Max . Before purchasing, you should find out which ones your hammer drill can work with.

Purpose and characteristics of crowns

You should start with such a useful product as a ring crown for wood. It is easy to recognize by its appearance: around an ordinary rod there is a metal (or bimetallic, that is, consisting of two layers of different metals or alloys) glass with teeth at the end. The design of the crown also contains a special element designed to remove chips from the working surface.

When the crown rotates, the cutting teeth, interacting with the workpiece, cut out a circle of the required diameter on its surface. Crowns are sold in sets, and one set can contain up to twelve pieces. They are recommended for use when drilling holes of large diameter (up to 15 cm) and depth (up to 11 cm) in wood products.

One of the benefits of using wood saws is that they allow you to make very precise holes. Moreover, you don’t even need to center and drill the surface first. And upon completion of the work, the master is relieved of the need to remove burrs.

By the way, crowns for drilling wood can be used not only on drills, but also on hammer drills and machines (lathes, drills and even milling machines). One of their varieties can be considered a circular saw. This is a saw bent into a ring, or a special drill with brackets on which the knives are fixed. Universal drill bits allow you to drill in almost any material.

How to drill tiles correctly. Tool selection

There are 2 options for drilling tiles: with a screwdriver or a hand drill. The screwdriver can be cordless or powered. A hand drill is suitable for drilling small diameter holes. It is worth using a tool stop - a plastic rod attached to the base of the drill. When drilling tiles, it is pressed against the surface, which helps keep the device at a right angle.

At home, you can use an electric drill or hammer drill if you first turn off the impact mode and reduce the speed.

If you need to make several holes in ceramic tiles, you will need a level. A jig will help you drill holes correctly - a thin plate with holes of different diameters that acts as a stencil.

The hardness of the tip of a drill bit suitable for tiles should be higher than the density of the tiles. Drilling of tiles is carried out only with suitable types of devices.

What's better

In order to get a high-quality result, use the following drills:

- Diamond coated. It allows you to accurately make a hole of any diameter in the tile. The cost of the drill is high, but for professional craftsmen their choice is preferable.

- With a pobedite tip. The winner is a super-hard metal-ceramic composite alloy, the plates of which are soldered onto the drill head for reinforcement. This drill is harder than tiles, and therefore can be used to work with fragile materials. It is affordable and sold in all hardware stores.

- Special. It is best to use them for drilling tiles, but they are also expensive.

If there is a need to cut a large diameter hole in ceramic tiles (for communications, sockets, switches), use circular drills:

- Ballerina. A circular adjustable drill with cutters that can be set to the required distance from the center, thereby adjusting the diameter of the hole. It requires skills to work with it.

- Circular crown with center drill. Crowns with a fixed diameter are very convenient and easy to use. No special skills required. It can be used to drill tiled cladding on the wall, but it is better to do it on the floor after the material being processed is securely fixed. Before work, ceramic tiles should be moistened generously with water to prevent overheating.

- Carbide cutter for tiles without center drill. This attachment can be used for drilling uninstalled ceramics.

If the tile is already fixed to the wall, and a hole is needed not only in it, but also in the wall, you can use a hammer drill with a carbide drill.

Forstner drills

Benjamin Forstner received a patent for a cylindrical drill for woodworking back in 1874. And since then it has been actively used. The working part of such a nozzle has two main cutting edges and a short centering tip. The profile of the product resembles the Latin letter Z with roundness at the top and bottom. On the jumper there is a cutting edge, and along the circumference there is a cutting edge, which, after creating the hole, also acts as a limiter, that is, it holds the tool at a given diameter.

The main cutting part of Forstner drills is made exclusively from hard alloys, and therefore these products have a long service life. The diameter of these carbide products can vary from 10 to 50 mm.

The Forstner drill bit was developed to make blind, flat-bottomed holes in wood of varying degrees of hardness. Nowadays it is also used for processing fiberboard, MDF, and chipboard.

The Forstner tip is much better than core drills for wood, suitable for accurate work with furniture fittings (locks, cup hinges, ties, etc.). This is where blind holes with a flat bottom and smooth and neat edges are often used. With this drill you can cut any similar hole in a short time.

Feather drills

The appearance of a feather drill for wood cannot be confused with anything else. By design, it is an elongated metal rod, one end of which ends in a hexagon, and on the other side there is a working part, which, in fact, is called a pen. The feather itself looks like a spatula with a chisel.

Pen modifications allow you to achieve fairly high performance. Of course, the ease of drilling directly depends on the hardness of the wood and the specific species. But a feather drill can cope with lumber, which is widely used in construction, without any problems. Another important advantage of feather products is their low cost.

You should choose drills of this type when you need to create holes of medium diameter in wooden products - up to 25 millimeters. But this is provided that not too stringent requirements are imposed on the geometry of future holes, as well as on the quality of their execution. Otherwise, feather products will not work.

It is worth saying a few words about special sliding pen-type drills. This variety is distinguished by the ability to change the drilling diameter. This is achieved thanks to the presence of fasteners for installing a movable double-edged knife, which extends to the required diameter in a given range. As a result, the range of tasks that such drills can solve is significantly expanded.

These are not all the varieties of wood drills that can now be found in specialized stores. There are also countersink, screw, tubular, flexible, stepped types. The latter are a set of cutting parts of different diameters on one rod, arranged in ascending order (accordingly, there are two-stage, three-stage and other modifications). Thus, two-start (two-stage) tools are used to drill holes in the frame for handles.

How to work

If you need to make small holes (no more than one or two cm in diameter) in a chipboard or solid wood at home, then a standard twist drill for metal can handle this. But large holes or those that require increased precision are drilled only with a special tool designed for working with wood.

The drill must first be sharpened well, otherwise it will not cut, but rather tear the wood, and chips will accumulate in the hole. When sharpening, it is very important to keep the cutting edges straight. Sharpening is carried out on an abrasive stone or manually with a small square file. It is optimal if the drill sharpening angle is 12°.

You should also first mark the centers of future holes. When marking, take into account:

- wood hardness;

- the degree of its splitting;

- location of cracks (if any);

- direction and depth of drilling;

- the presence or absence of nails and other factors.

The centers of the holes are pricked with a triangular awl to the depth of the diameter of the drill. When drilling holes of large diameters, their centers are pre-drilled not with an awl, but with thinner drills - this is necessary so that the tool does not fall to the side. The centers of deep through holes are drilled on both sides. And further drilling is also carried out on both sides.

If you need to drill a large number of identical holes in wood, then it is better to have several drills of the same diameter in stock and change them periodically.

Another important tip: the diameter of the drill for installing screws should be half a millimeter less than the diameter of the middle part of the screw. And, of course, if possible, it is better to use countersink drills specially created for this task.

Diamond

The active element of diamond crowns is a coating of natural mineral, which has no equal in hardness. Strong segments are laser welded on the edge of the cutter. They quickly cut concrete using fine diamond chips generated during operation.

Types of marking: M - only ordinary concrete, C - reinforced, T - high-quality.

The equipment is suitable for reinforced sections of walls, as it can easily handle metal. The cutter penetrates to any depth, leaves smooth holes and creates a minimum of noise.

Diamond bits are not designed to work in impact and combined modes. Set the rotary hammer switch to “ drilling only .

How to make a drill with your own hands

The easiest way to make a feather metal drill for wood. To do this you will need a regular nail. The nail head must be riveted, sawed and sharpened. It is necessary to take into account that the drill will rotate clockwise.

If you plan to work with chipboard, then it is recommended to give the hat the shape of a sharp spear tip. With this solution, the hole is obtained not by drilling and removing chips, but by simply inserting the drill into the material. And this option is suitable for drilling holes for screws.

To lengthen the drill, you can weld a piece of rod of the required length to the shank. A small extension of about 0.5 cm can be obtained by inserting a piece of chopstick into the chuck with a diameter slightly smaller than the shank.

A device for drilling holes with a diameter of 15 to 45 mm in wooden products can be created from a steel rod with a longitudinal slot and a piece of unnecessary hacksaw blade. The cutting edges of the blade are sharpened at an angle of 45°, inserted into the slot of the rod and connected with a soldering iron.

Note! Before you start working with such a tool, use a regular drill (its diameter should be slightly larger than the diameter of the homemade workpiece) to drill a guide hole.

Then the shank of a homemade drill is clamped in the drill chuck, and the protruding part of the rod is inserted into the guide hole. After this, you can proceed directly to drilling.

A thin drill can easily be replaced by a sewing needle if its end is sharpened from the eye side. The drill is also easy to make from annealed steel wire. The working end of the wire head is heated until hot (the metal should turn light red), and then dipped in sealing wax - this is the manufacturing method.

Preparatory operations for work

It must be taken into account that to prevent rotation, manufacturers create an irregularly shaped socket for fitting the tool. More experienced specialists remind you that for high-quality fixation it is necessary to tighten the thrust nut or bolt well. This will allow the cutting tool to be securely held in the grooves and not to become loose, deforming and bending the hole.

Example of the resulting hole

It is necessary to install the tool into the drill chuck only after all threads have been tightened. Then you can start drilling at the selected point. The process is practically no different from working with a classic drill. It is important during the operation to maintain maximum perpendicularity to the axis of rotation of the plane being treated. This factor is maintained in the first millimeters, then everything goes along the initially formed cylinder.

The number of revolutions for rotating the crown is also set in advance. It is worth considering that an increase in the diameter of a tool is combined with an increase in its vibration. This forces the use of more powerful drills if you take wood drills for large holes and large diameters. If possible, attach an additional handle to support and maintain perpendicularity.

When setting the rotation speed on a drill, you need to follow these rules:

- soft wood can be processed at speeds from 1000 (diameter 3.0-5.0 cm) to 2400 rpm (diameter 10-55 mm);

- for hard wood, it is advisable to increase the speed to 250 rpm (3.0-5.0 cm) to 600 rpm (1.0-1.5 cm);

- When using bits with carbide tips, you cannot lower the speed below 400-500 rpm, as the cutting edge will crumble.

VIDEO: How to drill a large diameter hole

Types of nozzles

At the same time, there are quite a lot of different types and purposes of drills that help achieve the desired result. There are several types of attachments that are used for wood processing, among them:

Each type is used in separate works, and also has a different structure, which allows the drills to be used for their intended purpose. When choosing a wood drill for a home tool kit, you should look for the largest selection, but so that the price matches. In this case, you need to focus on quality indicators and characteristics.

Twist drill bit for wood

This is a classic type of attachment that almost everyone associates with the general concept of this type of tool. The most important characteristics that are characteristic of each twist drill are its diameter, as well as its length.

The length of spiral nozzles can be from 80 millimeters to 60 centimeters. The range of working diameters of spiral nozzles is from 3 to 52 millimeters. For larger hole diameters, other types of nozzles are used.

According to their purpose, twist drills for drills can be divided into tools for working with wood, metal, plastic and other materials. The drill is attached to the drill using a hexagon on its end opposite the working side. The hexagon is inserted into a chuck with clamps that hold it in place.

Spiral nozzles, which have a diameter of no more than 10 millimeters, are usually flat at the end, although in terms of fixation this does not in any way affect the nature of the fastening. A distinctive feature of each wood drill is that it has a shank designed for directed movement deep into the material. It is designed to fix the axis of movement, and when pressed with the tool, a clear, even hole is drilled in the form of a round tunnel of the appropriate diameter. Without such a shank or with damage to it, the drill can slip out when pressed, which makes further work impossible, and the tool becomes defective and unsuitable for further use.

Most drills are designed for a specific operating mode, just as a standard speed is better suited for each individual type of work. Recommendation for 14mm or smaller drill bits is 1800rpm for softwood and 750rpm for hardwood. For average diameters of 16-25 mm, the optimal operating speeds are 1500/500 revolutions for soft and hard wood, respectively. Large diameters require low speeds of 500 for soft wood, 250 for hard wood. However, not all devices can cope with such speeds. For example, a drill with a length of 65 cm and a diameter of 51 millimeters will weigh approximately 3 kilograms, which is an overload for a conventional hand drill.

Distinctive features

Regardless of what material the crown purchased from Leroy Merlin will be used for, it has a standard design like all the others. It consists of the following elements:

- cutting head;

- elongated cylindrical or ribbed shank;

- guide drill.

The kit can be supplemented with a hexagon for high-quality clamping of a core drill.

Manufacturers offer two design options for wood crowns for deep drilling:

- non-separable solid metal structure for making a hole of the same size, for example, wood diameter 120 mm

Structure of a non-separable drill

- a collapsible design, which consists of a holder with a shank, to which a cutting ring of the required diameter is attached; for all mounted crowns there is a table in the instructions for use.

A stacked hole saw consists of several removable links of different diameters

In the first option, a solid ring is used, and in the second, an open ring in the form of a split cylinder is used. Quick ring changes speed up any machining process. Each cutting element has special technological holes for removing chips. They are made in the form of circles or slots on the side surfaces of the cylinders for small diameter tools and additionally at the ends for large ones.

Some craftsmen independently make a wood crown in their workshops, using a thick-walled metal pipe of the selected diameter.

Feather drill for wood

Designed for roughing holes of wide diameters in wood. The range of working diameters for which it is possible to work with feather drills is from 10 to 55 millimeters.

They are simple in structure and cost much less than regular ones. The main disadvantage of this type of tool is the lack of a mechanism for removing sawdust from the hole, which is why the work is constantly interrupted. At the same time, these drills perform well when working with wood chips and other materials. Thanks to their design, they can make shallow holes.

At the same time, the nozzles operate at speeds that exceed those for twist drills. The smallest diameters operate at a speed of 2000/1500 revolutions, and the largest ones at a minimum of 1000 revolutions if hard rocks are processed.

The guide point of a pen drill has two cutters on the sides, which can be sharpened in one of two ways. Double-sided sharpening (at an angle of 120-135 degrees) allows the pen nozzles to work in two directions - clockwise and counterclockwise. Single-sided sharpening allows you to work in only one direction, and the sharpening angle ranges from 75 to 90 degrees.

Forstner drill

Very often, this type of drill attachments is mistakenly called crowns, which is fundamentally incorrect. They differ from crowns both in shape and purpose. A Forstner-type wood drill is a specialized professional device.

Their main task is to make even holes with a perfectly smooth bottom. Due to the fact that they give the holes such an even shape, furniture makers often use them. The Forstner design helps remove all the sawdust from the bottom of the hole, and also creates a bottom without even the smallest irregularities. It is also possible to extend the drill bit, allowing for much deeper holes. The number of revolutions of normal operation for small diameters is 2400/500, for medium diameters - 1500/500, and for large diameters - 1000/250. The diameter range is from 10 to 50 millimeters.

How to properly drill metal with a screwdriver.

This article provides the most necessary and wide area of the main drilling attachment, which will help you decide and purchase the right product. Essentially, drills can be classified according to the type of material being processed:

- metal (including stainless steel and aluminum)

- wood and its derivatives (MDF, chipboard, etc.)

- concrete and brick

- ceramics and glass

Metal drill

a must have in stock for any household, as it is distinguished by its versatility. The main task is, of course, drilling metal and its derivatives. You can also use a metal drill to process wood, plastic and other polymer materials. Depending on their design and purpose, metal drills have several categories:

The metal twist drill is the most common and is used for drilling holes in metal. A cylindrical drill consisting of a shank and a working part with cutting edges. Such drills have a wide range of applications and sizes (from 0.5-20mm), and are variable for different drilling depths (extended metal drills).

A stepped (conical) drill for metal is used to create new holes and drill out existing ones in metal by gradually inserting the stepped or conical working part of the drill. The advantage of such a drill is the ability to make holes of different diameters using one unit. The disadvantage is that it cannot be used for drilling deep holes.

A core drill for metal or a crown for metal is used to create large-diameter holes, usually used in conjunction with a centering drill. The end cutting part can be coated with diamond coating or carbide, but more often it is a cutting part with a progressive arrangement of teeth made of high-speed steel R2M10K8 (cobalt content 8%).

Wood drill

It is very popular in our market, since wood is loved, respected and used in various spheres of life (construction, interior design, etc.). Depending on the planned operation, a huge range of types of this attachment opens up; let’s look at the most popular and effective of them:

A feather drill (feather) is a flat cutter with two cutting edges at the edges and a centering tip. The shank is usually hexagonal for better fixation. The pen does not remove shavings. The drilling diameter range is 6mm-40mm, depth up to 110mm, and when using a special extension for pen drills more than 400mm.

The disadvantage of such a wood drill is its tendency to jam at high speeds, which makes working with such an attachment require increased control. Working with a feather will not give you precise drilling and accuracy; it can tear up the outer part of the wood being processed.

Spiral wood drill with a double-band spiral cutting edge and a centering sharp tip. Their diameter ranges from 3-13mm, and their length reaches 150mm. There are options with a drilling depth limiter.

A Lewis drill is very similar to a twist drill, but with only one cutting edge in a spiral, the centering tip will be threaded. The shank must be six-sided or tetrahedral for better adhesion of the nozzle to the tool. A huge constructive role is played by grooves for removing chips, due to which this drill for wood can make holes of large diameter (up to 52 mm) and great depth (up to 800 mm). The Lewis drill is often used in stitching beams and logs, and in furniture precision drilling. The larger the diameter of such a drill, the fewer revolutions are required for its optimal operation.

The Forstner drill is a favorite among furniture makers. With its help, you can drill a blind, even hole with a diameter of 10 to 50 mm. The working length of 100 mm can be increased using special extensions. The main advantage of a Forstner drill is the accuracy and cleanliness of drilling.

Hole drills for wood or wood core bits are a metal ring with sharp teeth and a possible centering drill. As a rule, they have a universal stand, where a ring of the required diameter and a drill in the center are fixed. They are designed for drilling even round holes, including large diameter ones. Such crowns or a set of these crowns are convenient, for example, for cutting into a door lock. The range of sizes is very wide, from 14 to 210 mm.

Milling drills and countersinks are highly specialized attachments and are used less frequently, but they have their own important feature. A countersink with a depth limiter included is used for drilling holes, which are subsequently masked and serve as connections with bolts and screws. When complex shaped drilling and the creation of grooves of various shapes and configurations in wood are required, milling drills are required.

Wood crown

In its usual form, the crown has the shape of a bowl, which has teeth along the rim. To use it, a special device is used - a special drill chuck for a crown. The crown makes holes in thick layers of wood with a very large diameter. The range of possible diameters is impressive: 20 mm, 65 mm, 100 mm, 110 mm, 120 mm, 127 mm, 130 mm and more, for example, 150 mm.

The largest possible diameters, which are rarely used, are 150 millimeters. Working with such drill attachments is only possible with special equipment. A standard wood bit set can accommodate up to 12 and possibly more different diameters, typically the smallest being 18mm and the largest being 65mm.

One of the important features of the crown is that it is also used as a cutter for processing wood.

Thus, a crown is a multifunctional tool that is quite beneficial for woodworking. It can be used not only as a hole saw for wood, but also as a hole saw for wood.

Scope of application of the tool

The main task for which a core drill is used for wood is cutting a through hole. In most cases, it will be needed for the socket box. Also, in addition to a solid wooden surface, you can drill with this or a similar tool in other materials with similar characteristics or hardness:

- plywood;

- Chipboard or OSB;

- plastic bars;

- non-ferrous metals;

- drywall, etc.

For processing workpieces that are stronger than wood, it is preferable to choose core drills made of high-carbon steel (HCS) coated with sputtered carbide grains. If you choose high-speed cutting grades (HSS), it is recommended to give preference to more durable alloys similar to P12 or P18. They have higher durability than P6M5.

Using a crown without a center drill

According to current standards, the crown for socket boxes is selected with a circumference of 6.8 cm. However, it is often necessary to make larger holes, for example, 150 or 160 mm. Also, for technological or decorative purposes, craftsmen make 200 mm for wood.

To make holes less than 65 mm in diameter, you will need a holder with a 19 mm shank. If a large wood crown is used, for example, 90-110 mm or even 125 mm, then a reinforced holder of at least 3.2 cm in circumference must be used.

The number of teeth on the working part directly depends on the size and dimensions of the tool used. The larger the dimensions, the more teeth.

Segment saw for wood, 7 blades

A positive factor is a clean, smooth cylindrical surface inside simultaneously with the formation of a large hole in circumference in a short period of time. After working with the tool, the inner surface does not require additional processing or deburring, since the high cutting speed removes all possible flaws.

An important quality is that the selected area does not need to be centered in advance or drilled around the perimeter to make cutting easier and reduce stress. Accordingly, the final quality increases and the processing speed increases.