Choosing wood for furniture making

Components of a tree and its structure

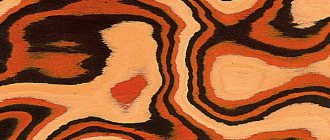

The structure and properties of wood are not the same in different cuts.

In a cross-section of the trunk, the bark, its cork and bast layers, and the cambium are distinguished; the wood, its sapwood and heartwood are visible, where the annual layers, medullary rays and pith are represented (Fig. 2). The core is located in the center of the tree trunk along its entire length. It has a loose structure, is fragile and is subject to rapid decay. In coniferous species, the core diameter is 3-4 cm, and in deciduous species it is slightly larger.

Fig.1 Tree trunk structure

Fig.2 Cross section of the trunk (top view)

Heartwood is strong, dense and hard, and more resistant to decay than sapwood, which consists of young cells that are less dense.

In most conifers, as experts note, in the cross section of the trunk, annual layers in the form of concentric circles are visible. Each year, with normal growth, one annual layer is formed. Its thickness (in the radial direction) varies among different tree species.

The width of the annual layers depends on the age of the tree, the species and growth conditions. In young trees, the annual layers are usually wider, except for willow, which has only narrow annual layers. Pines growing in the north have narrower annual layers than pine trees growing in southern latitudes. The properties of wood are characterized by the width of the annual layers. Conifers with narrow annual layers are more durable and resinous.

Pine with narrow annual layers of red-brown color is more valuable than with wide annual layers. Coniferous wood, on the end section of which in a radial direction of 1 cm there are no less than three and no more than 25 annual layers, is considered the best for making furniture. In deciduous trees, on the contrary, the wider the annual layers, the denser, harder and more durable the wood. This is typical for oak, chestnut, elm, ash, and elm.

In birch, beech, hornbeam, maple, linden, alder, and aspen, the wood does not have clearly defined annual layers and the width of the annual layer does not affect its quality.

The core rays are located in the trunk in the radial direction. They are found in most tree species, but their size, type and quantity depend on the species and growing conditions. Trees grown in the sun have more pith rays than those grown in the shade. The wood splits well in the direction of the core rays.

Thus, not only does wood of different species have a different structure, but also wood of trees of the same species grown in different conditions.

Advantages and disadvantages of wood of different species from the point of view of furniture production.

Pine is the most common coniferous tree. The color of its wood can be brown, reddish, yellowish and almost white with slight streaks of red. The best material for making furniture is obtained from those trees that grow on hills, dry hills, and sandstones. Their annual layers are located close to each other, and the wood has a dense structure, the annual layers are narrow. The structure of pine wood growing in humid places is more loose. When dry, pine is a light and pliable species for furniture work. It is planed well along the grain, with difficulty across it, but sawed across it is good, but poorly along it.

Pine wood glues well. Furniture is made from it (for this purpose, natural wood with a beautiful, pronounced texture is selected), frames of carpentry structures and structures for cladding with sliced veneer of valuable species.

is softer than pine, but has a large number of small and medium knots, which makes it difficult to use in furniture structures. The texture of its wood is inexpressive, less moisture resistant than pine, and more likely to rot, but its wood is less susceptible to warping, which is a positive quality of this material. Spruce is difficult to finish and glues better than pine. Widely used in mosaic sets due to its knotty texture. In furniture production it is used mainly for non-critical furniture designs that do not experience heavy loads during operation.

Larch occupies a special place among other conifers. Its wood has a reddish-brownish, sometimes brownish tint and is characterized by high strength (stronger than oak) and moisture resistance. Dry larch wood is processed well, although with prolonged processing of parts the sole of the tool becomes greasy. Larch is not very susceptible to warping, but during rapid drying, internal cracks may appear in the wood of the trunk. For finishing larch, experts mainly use nitrocellulose varnishes. The breed is used in furniture and mosaic work, and is used for making carved items.

Cypress and thuja are similar in properties to juniper, but their wood is wider-grained and darker in tone. Used for small carving work. Cypress does not crack or warp.

Yew has red-brown wood with dark and light veins. Its sapwood is light, almost white. Yew wood is strong and hard, with a significant number of knots on the trunk. It is almost not affected by the wormhole and is little sensitive to atmospheric changes. Plans and polishes well, paints well, especially black. In carpentry, yew wood has a variety of uses: it is a good material for carving; Yew veneer is highly valued in furniture making.

Siberian fir is used on a par with spruce, although it has reduced physical and mechanical properties.

Oak wood has sufficient viscosity and is well processed with cutting tools. After lying in the water for several decades, it acquires a silky dark purple color with a greenish tint (like a “raven’s wing”). Its hardness is higher than dry wood, but its fragility is also higher. Processing bog oak is difficult. Having a lot of tannins, oak wood pickles well.

Oak wood is widely used for the manufacture of furniture, parquet, objects of decorative and applied art, as well as in cooperage. Oak veneer is used for veneering low-value species, plywood, particle boards, etc. Oak is used in mosaic work and for large carvings; as experts note, it is inexpressive for small profiles. Oak wood does not accept alcohol varnishes and polishes well, but it adheres well.

Ash is similar in some qualities to oak, although it does not have pronounced core rays. When bleached, it acquires a grayish tint. Bends well after steaming. When dried, ash cracks little; Due to its high viscosity and strength, wood is difficult to process. Ash is easily damaged by wormholes, so its wood is subjected to antiseptic treatment. The sapwood of an ash tree is clearly separated from the core. Its texture is beautiful, brownish-yellow in color. In unfavorable conditions (humidity, dampness), ash quickly rots.

Flexible and durable, ash wood is recommended for making furniture. Ash is poorly polished and, like oak, requires pore filling. For ash, decorative coating with nitro varnishes or waxing is recommended. Due to the frequent growths on the trunk and pronounced texture, ash wood is widely used in mosaic making.

Beech has a strong and hard wood; its strength is not inferior to oak. In its pure form, beech does not have a pronounced texture, but in tangential and radial sections its wood is very beautiful. These decorative qualities are used when covering furniture with sliced veneer. Beech is hygroscopic, so it is not used for the manufacture of products located in a humid environment. The wood dries quickly and does not crack. Beech is easy to split, saw and process with cutting tools, and bends well when steamed. Difficult to polish. The use of beech is varied: from planing tool blocks to solid wood furniture. The wood is successfully used in carving, although it has high hardness, and also in mosaic work. It is well finished with nitro- and polyester varnishes, waxing, painted in various solutions and bleached.

Hornbeam is also called white beech. It has a hard, durable and dense wood with a whitish-gray color. The texture of hornbeam is not bright, like, for example, ash; There are light dots scattered on a smooth matte background. Often this species has a cross-layered wood structure, so the hornbeam is difficult to split. The sapwood does not make much difference in the transition to the heartwood. After drying, hornbeam is almost not subject to warping, its hardness becomes higher than that of oak. It is difficult to handle with cutting tools. The use of hornbeam in furniture production is varied, although not as widespread as oak, ash or beech. Used in mosaic making. Hornbeam lends itself well to finishing and etching.

Common birch is distinguished by its high strength, uniform structure and color, medium density and hardness. Its wood is not resistant to rotting and is used mainly for the manufacture of plywood, peeled veneer, chipboards, and plastics. It is used in furniture production and in carpentry in general. Birch is easy to process and finish; when etched, it can be easily painted to resemble more valuable species. Wood bends well when steamed. Birch burls (growths on the trunk) provide very valuable material for mosaic work. Due to the homogeneity, viscosity and hardness of the wood, birch is also used for the manufacture of carved products. Disadvantages of this breed: it takes a long time to dry, it pricks easily, it cracks badly, warps, and is susceptible to wormholes.

Karelian birch has tough and hard wood and is easy to carve. Among light deciduous species it has no equal in the beauty of its texture. It is highly valued in mosaic works and as an ornamental material. Tannins contained in Karelian birch wood contribute to its high-quality staining and tinting in various colors. Due to the curling and entanglement of wood fibers, this species is almost unbreakable; furniture made from it is very expensive.

Scotch maple has strong, hard and scratchy light yellow wood. Belongs to coreless breeds. The wood can be processed well with cutting tools and is not resistant to dampness, although it warps a little. Thanks to tannins, it takes on the desired color and tone in metal salts. Maple, as experts note, is perfectly cut and polished, therefore it is used for carving work with small profiles. Wood is often imitated to resemble other species with a smooth structure. Maple is used to make furniture, sliced veneer, parquet, musical instruments, etc. Its wood hardly cracks, so decorative dishes can be made from it.

Sycamore is a variety of common maple. Valued in mosaic works.

Bird's eye maple has a very beautiful, distinctive wood grain. The facing material made from this type of maple is highly valued. This species is sometimes called "sugar maple."

Linden , like maple, is a coreless species; has light, white wood. The linden texture is not expressed. It is used in the form of peeled veneer for the manufacture of plywood. In mosaic works it is used for large and medium-sized inserts (without textures) in sets of ornaments. Linden is one of the species that hardly cracks and dries out little. Due to the uniform texture and uniform structure of wood fibers, it is the best material for carving. Its wood is resistant to dampness, but is susceptible to wormholes. Linden has almost no tannins, so it is difficult to pickle and paint. For coloring, wood is saturated with tannins.

Poplar (regular and silver) is not widely used in furniture making due to the softness of the wood. The sapwood of the poplar is pure white, closer to the core it is grayish. The growths and swellings on the trunk of this tree have an expressive texture, which is highly valued in mosaic work and furniture cladding.

Elm has a dark core and clearly visible annual layers, which in a radial section form a beautiful pattern. In terms of hardness and some other qualities, elm wood is close to oak. Over time, like oak, it darkens. Experts note that elm wood is flexible, dense, and is used to make handles for percussion carpentry tools, carpentry workbench frames, etc. Elm is difficult to chip, polish, and process with cutting tools, although it is successfully used in mosaic making. Elm burls, thanks to the beautiful texture of the fibers, have advantages over poplar, walnut and even Karelian birch burls.

Elm wood properties resemble elm, but it is harder. The color of the wood is grayish, with beautiful oblong spots.

Aspen is in many ways similar to alder and is easy to carpenter. Used in the manufacture of plywood, shingles, matches, etc. Also used in carvings.

Pear has beautiful pinkish, sometimes yellowish-white (wild pear) wood. In old trees it is usually darker than in young trees. Pear wood is dense, without noticeable annual layers. It is perfectly planed and cut in all directions. To increase hardness, pear wood is placed in water and kept for a long time, after which it is dried for a long time in the shade. After drying, it acquires a brownish tint. In furniture production, pears are often tinted black. Due to its dense structure, the wood polishes well and provides an excellent material for the smallest carving profiles. When dried, the pear almost does not warp or crack, but is susceptible to wormholes.

White acacia is considered the hardest of the hardwoods. The color of its wood is yellow; The annual layers are clearly visible in the sections. Dry acacia is difficult to process. The wood does not crack or warp, has a high friction resistance, is very elastic and polishes well. In air and under the influence of light, it noticeably darkens over time, making the texture more expressive and brighter. It is used in the form of sliced veneer for mosaic work.

Walnut has a very beautiful texture with a wide range of tonal transitions. The older the walnut, the more valuable its wood. The burls of this tree in the form of sliced veneer are an excellent material for furniture work. Walnut is highly valued by woodcarvers, as its wood, although dense, is malleable. Thanks to the presence of tannins, its wood is easily tinted and painted in various colors.

In mosaic works, color transitions are made not only with painted, but also with bleached veneer. By soaking veneer sheets in hydrogen peroxide, you can achieve absolute snow-white wood. Walnut is often tinted into ebony.

In terms of texture, color, tonal transitions and viscosity (due to which the veneer does not crack when cutting out the most complex and small details), walnut wood is the best material for mosaic work. Widely used in carpentry, especially in furniture making.

The apple tree has a slightly textured, pinkish, reddish or brownish color with slight deviations in tone. Its wood is moderately hard and dense, is well finished, polished and processed with cutting tools, but is highly warped. In furniture work it is used for sets of portraits, landscapes and geometric patterns.

Chestnut has several varieties; Of these, the most famous are edible chestnut and horse chestnut. Due to its softness and even density, edible chestnut is used in furniture production and for carving. In its structure, this species is somewhat similar to oak and ash, but in a radial section it does not have the luster of the core rays characteristic of oak. Horse chestnut is oblique and grayish in color, reminiscent of pine. It has durable wood and, thanks to tannins, lends itself well to etching in solutions. It is used in furniture and mosaic making in the form of sliced veneer.

Rowan has hard, dense, finely layered wood. In furniture production, only well-dried wood is used. The texture of rowan is weakly expressed.

Sycamore and plane tree (eastern plane tree) grow, like elm, in the south. Their kernel color is brownish-brown. A radial cut produces a beautiful pattern of wood fibers, which is successfully used in mosaic work. These rocks are moderately hard. Processing them with a cutting tool due to the cross-layering is difficult. The wood polishes well.

Source

Elm

Crowning and cutting down trees in Nizhny Novgorod or the Nizhny Novgorod region - contact us!

Send a request

Application for cutting down trees✖

The elm is a tall tree without thorns or thorns, growing under suitable conditions up to 35 m. There are 16 species of elms, distributed in the temperate latitudes of the Northern Hemisphere. In the ancient Slavic language, the word “elm” means a flexible rod - a connecting part for various sleighs and carts. The tree is popularly known under other names: elm, elm, birch bark.

General information about elm

Elms are durable, living up to 200-300 years.

Large tree with a dense crown. The branches are spreading, with dense lacy foliage. Blooms before the leaves bloom. The leaves are rough on top, with sharp-toothed edges. The flowers are small and inconspicuous. The plant is pollinated by the wind. The fruits are winged nuts.

The bark of young elms is smooth. The bark of old trees has grooves and cracks. They are characterized by low demands on soil moisture and humus.

Elms are fairly unpretentious plants that tolerate both too little and too much moisture. Most species are frost-resistant. Trees are used in protective afforestation and urban greening.

Rhizome and crown of elm

Elm is characterized by thickening of the base. The roots can grow together easily. The thickness of individual roots sometimes exceeds the thickness of the trunk. This fact should be taken into account when planting elms near buildings, fences, and asphalt-covered areas.

The wood of the plant is hard and flexible. Resembling a nut, it is considered a valuable breed. Resistant to rotting due to constant dampness.

Elm trees are often attacked by pests - elm leaf beetles. Trees sometimes suffer from dangerous fungal diseases. The death of huge branches can lead to the destruction of buildings and fences. It is necessary to monitor the condition of the crown and trunk of the elm, and promptly cut out branches affected by diseases or pests.

Elm wood at the service of man

Due to its resistance to rotting, the wood is used in the construction of underwater structures and for the production of stakes. Trees are planted on hilly slopes and ravines to retain soil.

In the Middle Ages, elm trunks hollowed out from the inside were used as water pipes. The branches, containing oils, fiber and proteins, serve as feed for livestock in rural areas. Elm bark tincture is prescribed for dropsy and chronic rheumatism.

Elm wood belongs to the ring-vascular species, with characteristic rings of different shades. It is distinguished by its strength, elasticity, and viscosity. It is difficult to prick, but it is perfectly processed.

Many cabinetmakers like elm as the most beautiful European species. Wood is widely used in the furniture industry and shipbuilding.

spil.su

The best tree for firewood. Full overview of breeds

The best firewood is free. But, if you have to pay for firewood out of your own pocket, then it’s worth figuring out what you’re choosing from. Not all types of wood produce the same results, and knowing a few key characteristics will help you choose the right wood for your stove or fireplace.

First of all, I’ll go through the main species that are more often found at sellers and in our forests. Let me just make one digression: different types of firewood differ in price by no more than 25%, since the costs of cutting, sawing, and delivery remain the same. At the same time, the content of conventional “calories” in cheap aspen, pine, poplar can be 50% lower than in expensive ash and hornbeam. You will end up paying a lot more...

Which tree is the best for firewood?

Why are some tree species better for firewood than others? It is based on two factors: density and water content. The denser and drier the wood, the better it will burn and the more heat it can produce. Hardwoods are more efficient than softwoods because they are denser and burn longer and hotter. Conifers burn quickly, tar and smoke, but are well suited for quick burning.

Beech

It is easier to show indicators of heat performance, combustion temperature and main characteristics in the form of a table. The better the wood, the higher the tree is on the list.

| Breed | Characteristics | Heat of combustion kW•h/kg | Combustion temperature C |

| Ash | It flares up perfectly, burns stably, cleanly and hot even when freshly cut. Doesn't smoke and almost doesn't spark. The smell when burning is neutral. Low humidity, ready after 6 months of drying. 3.5 storage meters of ash firewood approximately correspond to 6301 kW/h of electricity, 890 liters of propane or 586 cubic meters of natural gas. | 4,1 | 1044 |

| Beech | It burns well, but it sparks and spits. Requires longer drying (up to 15% humidity dries for 3 years under natural conditions). | 5,5 | 1040 |

| Hornbeam | Dense fibrous wood. Hard to light, but burns hot and slow, producing a lot of charcoal. One of the best options for winter heating. | 4,2 | 1020 |

| Oak | It is a slow growing tree and therefore has a high density. A good choice for keeping a fire going at night when mixed with fast burning wood (birch and acacia are good companions). It is recommended to age oak firewood for at least two years - it dries out very slowly. It emits a sour, vinegary smell when burning and is not suitable for barbecuing. | 5,5 | 900 |

| Birch | It burns hot and relatively quickly, depending on the variety it differs in heat capacity and density. Birch bark is excellent for splitting, but has a porous inner layer that retains moisture for a long time, so it is advisable to chop birch firewood for uniform drying. It is better to mix them with denser rocks. | 4,3 | 816 |

| Acacia | Even freshly cut wood burns well. Typically, acacia firewood is placed on par with birch firewood. Lots of heat, flares up without problems, smells very nice. From personal experience I am 100% satisfied with acacia. | 4,3 | 708 |

| Maple | The density is average, but well-dried maple is almost as good as ash and burns evenly and for a long time. It smokes minimally, doesn't spark, quivers well, and smells nice. It is better to burn during the felling season; it is prone to rotting due to the high sugar content. | 4,3 | 700 |

| Linden | It is close to pine firewood in terms of basic indicators, but does not have the disadvantages of resin and pungent odor. | 4,2 | 660 |

| Pine | Pine burns easily, brightly and quickly. You don't have time to throw it up. Very resinous, like most conifers. Emits acrid smoke during combustion and smoldering. Suitable for light burning, but pine is not very profitable as the main firewood. Sawing pine is also not very pleasant - the chain will be covered in resin (everything will be covered in resin). | 4,4 | 624 |

| Aspen | There is a legend among bath attendants that aspen firewood loosens the carbon deposits on the walls of the stoves and all that remains is to clean the soot pans. Burns easily and quickly, leaving almost no charcoal. Heat dissipation is low. | 4,1 | 612 |

| Alder | The same rumors about cleaning the stove as about aspen firewood. They don’t tar, they are rather weak for heating, but they are good for a bath. Used for smoking. | 4,0 | 552 |

| Poplar | Poplar is not suitable for main winter firewood, as it burns out instantly. But this is its advantage if you need quick kindling or if you need to sit by the fireplace for a couple of hours during an autumn visit to the dacha. It burns well even with large logs; the wood is very porous and light. Some studies put the calorific value of poplar at 5.3 kW/h e.e. (most likely this is not true). | 4,0 | 468 |

| Nut | A well-dried walnut is comparable to pine in terms of burning time. Burns easily and cleanly, does not smoke. | 4,2 | 600 |

| Fruit | Cherry, apple, pear, apricot - burn with good heat release, smell pleasant and do not smoke. Good drying is necessary for at least 6 months before the heating season. The best firewood for barbecuing and smoking. | n/a | n/a |

In different sources, data on calorific value differ, sometimes in megajoules, sometimes in calories. Couldn't find any decent reference books. The thermal energy rating (BTU) for 50 breeds is here.

By the way, on the American forum of maple syrup producers there is one thought that runs like a red line:

Differences between the calorific value of different firewood are valid only under the same laboratory conditions, and it is better to focus on the availability of wood and the quality of drying. Basically , burn what you have, just make sure it's dry . Their experiments with automatic stoves show a difference of no more than two minutes in refueling the firebox between soft and hard wood. The difference is significant only in the speed of ignition.

I guess this is not far from the truth.

Breeding

Elms reproduce by self-seeding. Their seeds ripen in May-June and lose their viability in a short time. Therefore, only freshly collected material will be suitable for planting. In nature, they can also reproduce by shoots and root suckers, but for amateur nurseries such methods are ineffective when breeding trees.

It is recommended to store elm seeds in conditions of good ventilation for no more than one week until sowing. A couple of days before planting, they are moistened and treated with a fungicide. Planting sites do not require preliminary preparation, but you can add a little mineral fertilizer to the soil. The seeds are sown in rows at a distance of 20-30 cm between the holes at a shallow depth - only 1 cm. They are covered on top with hay, moss or a thin layer of soil and watered well. Shoots appear within a week. In the first year of life, elms grow up to 15 cm, in subsequent years they add up to 40 cm.

Good firewood. How is that?

For any tree to burn cleanly, efficiently and safely, it must meet several criteria, which do not always depend on the species.

Even ironwood firewood can be very bad if it is damp. Most of the energy will go into evaporating moisture and releasing smelly, toxic creosote. Or for burning resin:

Drying pine

You can determine whether a tree is dry enough by eye in several ways:

Source

How to choose a wood type?

Based on their performance characteristics and aesthetic indicators, we strongly recommend making your choice in favor of oak or ash. Both breeds have incomparable strength, flexibility, ductility, and excellent texture.

We work with oak, ash, larch, pine, beech, birch, spruce, as well as other types of wood. I have experience working with solid cherry, maple, linden, Canadian cedar, iroko, and teak. We use only high-quality selected wood of extra class and 1st grade, without chips, cracks, falling knots and other defects.

Based on the totality of strength, wear-resistant, and aesthetic indicators, the rock priority scale, from the point of view of professionals, is as follows (starting from the best indicators):

All wood undergoes multi-stage technological processing in order to enhance natural strength parameters and improve aesthetic qualities. We produce furniture panels from natural solid wood that have reliable performance characteristics: strength, stability of size and shape, resistance to warping and cracking. Therefore, for the customer, the criterion for choosing a wood species is:

Thanks to professional processing, the strength and performance qualities of solid wood are maximally stabilized. However, the selected breed still has an impact on the durability of the products.

When choosing a type of wood, the customer will have to focus on his taste preferences, evaluating furniture panels made from solid wood of various species.

Use in folk medicine

All parts of the tree have medicinal properties. The cones begin to be harvested in late autumn, when they are fully ripe. They are cut and dried at room temperature.

When properly prepared, the fruits should have an astringent taste and be dark in color.

- Leaves begin to be harvested in early summer. They contain essential oils, tannins and organic acids. They are used as a hemostatic, diaphoretic and antimicrobial agent.

- A decoction of alder fruits is used for ailments of the gastrointestinal tract, allergies and rheumatism. The infusion helps with colitis and digestive disorders, for cleansing the skin and healing wounds.

Alder has proven itself well as an expectorant for bronchitis and tracheitis, antipyretic and diaphoretic for colds.

Preparations made from alder are usually safe for human health. Contraindications include individual intolerance, and an overdose can have a negative impact on health.

Description and characteristics of furniture panels

The furniture panel is made of wooden blocks (lamellas), firmly glued together into a single rectangular panel. Depending on the gluing (connection) technology, spliced and solid-lamella structures are distinguished.

This is a wood board formed from lamellas glued along the width and spliced along the length - identical wooden blocks. Along the length, the lamellas are fused into a mini-tenon. Along the width they are glued together into a smooth fugue. The method is reliable and is used in the manufacture of standard products in 100% of cases.

Compared to solid-lamella structures, spliced panels are considered more reliable, since the tension of the fibers in adjacent bars is uniform and, accordingly, the entire structure is more stable and durable.

This is a wood board formed from lamellas glued together only along the width. The gluing method is using a smooth fugue. The width of the lamellas is 40-45 or 25-30 mm. Thickness varies from 10 to 150 mm.

Compared to spliced models, solid-lamella structures have a more uniform texture and color range, as they consist of fewer lamellas.

Planting seedlings

You can make your work easier by purchasing ready-made seedlings. Planting and caring for seedlings includes steps such as:

- Planting in open ground. The seedling should be placed in a prepared hole in soil that has been previously moistened and fertilized.

- Constant hydration.

- Loosening the soil around the root system.

- Wrapping up for the winter from the harsh effects of frost.

- Timely pruning (you need to start at 4 years old). It is best to prune the crown from October to April.

Choosing the type of wood for furniture panels

An exceptionally strong naturally-occurring material with a beautiful, uniform texture that maintains stability of shape and size during temperature changes and changes in humidity levels. When painted, it acquires a noble, uniform shade. It does not deform, is durable, and retains its aesthetic properties for decades. Practiced in the production of furniture and all types of interior decoration: window sills, tabletops, bar counters, stairs, wall and ceiling panels.

Our recommendations:

Investments in oak interior items are economically justified, since you get products that will last for centuries, plus the aesthetic pleasure of the magnificent texture. An unsurpassed material for interiors in a classic style. To save money, choose finger-jointed oak panels. If aesthetics are a priority, we recommend solid-lamella designs.

It is distinguished by a picturesque texture of predominantly light colors. Ash is not inferior in strength to oak. Due to the high density of fibers, the wood is very hard, so solid ash is difficult to cut. However, the products turn out to be practical and decoratively attractive. When tinted, the array acquires a brighter and more pronounced texture with an impressive variegated pattern. Just like oak, ash is suitable for making all types of interior products. Due to the complexity of processing, high strength and aesthetic characteristics, it is almost not inferior to oak in price.

Our recommendations:

Ash, like oak, has no disadvantages. Furniture panels made of ash are hard, dense, evenly chipped, and do not warp during use. If in your interior, instead of a classic style, you prefer finishing with a non-trivial, bold wood pattern, do not hesitate to choose an ash panel. To save money, we recommend the spliced option. In terms of price, products made from finger-joint panels will cost approximately the same as those made from solid beech or larch, but in terms of strength, wear resistance and beauty, finger-jointed ash panels are significantly superior to beech and larch.

Wood has softness and uneven hardness of the fibers. The array contains layers with different densities. Because of this, when sanding a panel, it is impossible to achieve a consistently smooth surface, as is the case in oak or ash. There are resin pockets in the massif. The advantage of solid larch is its high resistance to moisture, as well as its low price.

Our recommendations:

Compared to oak and ash, the structure is more prosaic. We do not recommend larch for luxury interior products due to its modest, mediocre aesthetics, and also because the wood, due to its softness, is more susceptible to scratches and chips during use. However, if you are choosing between larch and pine, then in terms of performance characteristics it is better to give preference to larch.

The tree is a strong species with a hard texture. It cuts and polishes well, but is susceptible to temperature changes. The array reacts to temperature changes of even 3-4 degrees, which increases the risk of deformation and warping. The change in fiber density under the influence of temperature can be felt tactilely, since in this case waves are formed on the surface. It is no coincidence that professionals classify the species as an ever-living tree.

Our recommendations:

Just like beech, the species belongs to the ever-living trees. The array responds to temperature and even lighting. The slightest changes in the surrounding space can provoke warping and end cracks. At the same time, the array is well cut and polished. Birch makes original interior compositions and decor. The heterogeneity of the structure is manifested in the uneven color of the surfaces.

Our recommendations:

The advantage of birch is its cost - the price of solid wood is 2-3-4 times cheaper than oak. However, we recommend that you think carefully before choosing birch products. The products have a distinctive decorative style, but are subject to a high risk of deformation.

Refers to soft tree species with pronounced oblique layers in the structure. It is characterized by the presence of resin pockets in the array, which remain noticeable even after repeated tinting. When sanding, due to the cross-layer, it is difficult to create a consistently flat surface and uniform color. Due to the fact that some of the fibers in the array are softer than others, waves may be present on the surface. Due to its softness, the rock is susceptible to chips and scratches, which are clearly visible on the surface. The same goes for spruce and other conifers.

Our recommendations:

In terms of price - the cheapest solid wood material. However, the work (professional processing) is expensive, which makes the choice in favor of pine irrational. Since our craftsmen are focused on high quality products (in terms of aesthetics and durability), we do not recommend pine for facades and solid interiors. Solid wood is suitable for making budget furniture and is not suitable for finishing wood surfaces on the front side.

Evergreen deciduous plants

Coniferous or evergreen deciduous trees are also used in the design of homestead areas. Today there are many varieties of trees and shrubs that are capable of decorating a site with their fresh and bright crown throughout the year.

Rhododendron

More than 600 species of rhododendron grow in the world, some of which are deciduous, and some are evergreen. One of the most popular genera is azalea.

Azaleas are heat-loving, require careful care, they need acidic soil and regular fertilizers.

Boxwood

A slow-growing, unpretentious plant that in Russia grows mainly on the Black Sea coast.

One of the most ancient shrubs used for landscaping. Since boxwood easily tolerates pruning, it is well suited for creating hedges and sculptural compositions.

Euonymus

A small tree with an openwork crown and small leaves that turn into bright and unusual colors in autumn

There are also large varieties, the crown width of which can reach 10 m. Dwarf and creeping varieties are often used in decorating areas, effectively entwining fences and hedges.

Recommendations from professionals: resume

Based on their performance characteristics and aesthetic indicators, we strongly recommend making your choice in favor of oak or ash. Both breeds have incomparable strength, flexibility, ductility, and excellent texture.

With comprehensive professional processing, products acquire a variety of shapes and beautiful colors. The material cuts well, and therefore craftsmen cut out configurations of any complexity from it. The main advantages of oak and ash are durability and impeccable decorative appeal. In our work we use high-quality finishing materials, and therefore the products do not lose their environmental friendliness.

Source