Wood has been used by humans for a long time for the construction and decoration of houses, the manufacture of furniture and interior items. This material remains popular today due to its environmental friendliness and decorative qualities. However, wood products require protection from external damage, minor scratches, moisture, and dirt. To protect wood and to emphasize the texture and beauty of natural patterns, various coatings are used.

Among the possible wood processing options, waxing has the advantage of being an environmentally friendly method that uses natural products. Thus, many wooden products coated with wax can be safely used even in children's rooms. The advantage of wax over varnish is not only its naturalness, but also that, while covering and protecting the surface, it does not clog the pores of the wood, and the wood breathes. Unlike varnishes, which create a film. At the same time, the appearance only benefits, the water-repellent properties of the wax are good, and the coating is durable.

Scope of application of liquid wax

Depending on the consistency and composition, wax is divided into liquid, solid and water. Each type of wax has its own area of application. Thus, liquid wax is especially convenient when it is necessary to treat a surface with a complex relief shape. For example, furniture richly decorated with carved elements. Hard wax is applied with a piece of soft cloth, and in this case it will not work. Liquid wax is applied with a brush, easily spreads over the surface of any shape, and is used to cover the most complex and delicate decorative elements. It is possible to play with the color saturation depending on how many layers of liquid wax are applied. There are options to make the surface shiny or matte. As a rule, liquid wax for wood contains beeswax and a natural solvent – turpentine.

Do-it-yourself wood waxing composition

The recipe for preparing the composition is simple.

You need turpentine, wax, rosin.

In proportions: 100 g wax, 50 g turpentine, 20-25 g rosin

The wax is melted, turpentine is added, and mixed thoroughly. Next, add rosin and mix thoroughly. Remove from heat and pour into a tin jar.

That's it, the composition is ready. It can be used.

Subscribe to our Yandex.Zen channel

Making liquid wax at home

This wax can be prepared at home. To do this, you will need beeswax and turpentine in a 1:2 ratio to obtain a liquid product. The wax is crushed and melted in a steam bath or in a microwave oven. Then carefully and constantly stirring, pour in turpentine. If the mixture turns out to be too liquid, the procedure is repeated, heating the solution and adding more crushed wax. Sometimes a small amount of "carnauba wax" is added. It is not a bee product, but a hard tree resin extracted from palm leaves in Brazil. Thanks to carnauba wax, the coating becomes stronger. Depending on what kind of wax is used, a waxing composition of different shades is obtained. So, to preserve the natural light color of the wood, it is recommended to coat it with a composition based on bleached wax. Other options give rich honey tones. When working with turpentine, you should follow safety precautions and ventilate the room well. Liquid wax based on linseed oil. Cooking at home. Vegetable oils can be used as solvents instead of turpentine. Thus, the result is an absolutely safe product with a pleasant smell, which can even be used to coat children’s furniture or wooden toys. To prepare this product at home, take natural beeswax and linseed oil in a ratio of 1:4. Flaxseed oil should be boiled first. Sometimes it is replaced with olive oil. But flaxseed is absorbed much better, so it is preferable to use it. Beeswax is crushed and combined with vegetable oil in a glass container. Then it is heated in a water bath. You can use the microwave. The finished mixture can be stored for a year without losing its properties. Store in a closed container in a cool place, avoid exposure to direct sunlight.

Industrial liquid wax

Substances that accelerate the drying process are usually added to industrially produced liquid wax - driers, rosin esters to enhance adhesion, and various others to improve the elasticity and wear resistance of the coating. Therefore, it is sometimes more convenient to use, and the waxing process takes less time. Liquid industrial wax is also tinted. After applying tinted wax, surfaces of different color shades are obtained. From brown and bronze to mahogany and ebony - there is something for every taste. Experienced craftsmen can prepare a coating composition at home that is ideal in consistency on the first try; beginners will have to experiment. Therefore, ready-made industrial molds are more convenient for beginners.

Pros and cons of wax protection for wood

Among the many advantages of waxing wooden products, the main ones can be mentioned, such as moisture resistance, reliable protection against microbes and fungal infections.

- Regardless of the components of the wax composition, the strength of the products increases, and they better withstand the effects of many adverse environmental factors.

- Preparations based on natural substances are safe to apply to wooden surfaces at home and in factories.

- Wax-coated objects retain the natural warmth of the material and make the tactile sensations more pleasant.

Waxing the surface is one of the most attractive ways to transform a wooden product into a beautiful and unique piece with a shiny surface.

Among the undeniable advantages there are also disadvantages, for example, almost all wax solutions are sensitive to alcohol-containing preparations.

Strong alcoholic drinks can leave unsightly stains on perfectly smooth wooden surfaces. Wax also changes color when exposed to hot objects.

Applying liquid wax

It is more convenient to apply liquid wax to a product with a hard brush, especially when it comes to embossed decorative elements. Before the first use, a new brush must be cleaned - remove excess hairs that are poorly attached and will immediately end up on the surface, which will not decorate the coating. The most suitable brushes are made from natural bristles; brushes for oil painting are suitable. There are also special brushes for liquid wax on the market. They are distinguished from ordinary brushes by the bristled bristles at the ends. On a new wooden product, homemade liquid wax is applied in one layer. After which the wooden surface is left for at least 1 hour. After the composition has been absorbed, its excess is removed with a piece of clean cloth. Otherwise, greasy stains may remain on the surface. Any non-lint soft fabric, even a waffle towel, is suitable for these purposes. The result is a beautiful, noble matte surface, the texture of natural wood becomes apparent. If desired, you can apply another layer of wax, and then polish the product using a cloth or a roll of thin metal wire. In this case, the surface will acquire a characteristic shine. For the second layer you need very little composition, since the main part has already been absorbed into the pores of the wood.

Surface preparation before applying liquid wax

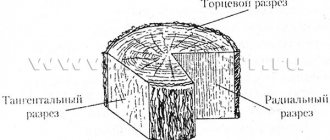

If the wooden product is not new, but we are talking about restoration, for example, then the surface must be carefully prepared before applying liquid wax. First, remove the old varnish or polish. A solvent is used for this. A single treatment will not be enough; the procedure is repeated several times until the old varnish is completely removed. The residues are carefully washed off with warm water, and the most solvent-resistant areas are rubbed with sandpaper. After this, the wood is rubbed with a stiff brush in order to remove the old coating even from the pores and grooves. After drying, the products proceed to the final stage of preparation. Sand the wood with a sharp carpenter's knife - a scraper or sandpaper. All manipulations are carried out strictly in the direction of the wood fibers. Moreover, there should be no protruding fibers left - everything is cut off and sanded. The result should be a perfectly smooth matte surface, now the wood is ready to be treated with liquid wax. The further application procedure is the same as in the case of a new surface - cloth or brush, in one or two layers, in the direction of the grain.

Application of industrial liquid wax

Ready-made industrial forms of liquid wax are applied in accordance with the instructions on the packaging. Manufacturers include various substances that affect drying speed. There are products that, after applying the first layer, are not recommended to be left on the surface for more than 10 minutes, after which they should be immediately wiped with a cloth to remove excess coating. Some compounds take longer to be absorbed. Some manufacturers offer liquid wax in spray form. Its composition does not differ from its analogues applied with a brush, but is available in the form of a bottle with a sprayer. Just shake the can and apply the composition to the surface from a distance of 25 cm. After a while, wipe with a piece of soft cloth, evenly distributing the coating. After drying, the product can be polished to a shine if desired. Liquid wax in the form of a spray is produced both colorless and tinted. In any case, it is always worth doing a test painting of a small area before starting to treat the entire surface of the product. According to safety precautions, all materials soaked with liquid wax during work, such as rags and sponges, should be thrown away or stored in airtight containers. It does not spontaneously combust, but is flammable. The room should be ventilated during and after work.

Waxes with oils

To provide the tree with the most reliable protection, it is impregnated with oil before applying wax. Professional formulations can significantly simplify the processing process.

For example, products from OSMO contain oils and waxes, so they retain all the properties of a natural product:

- Penetrates well into the wood structure and provides deep protection;

- Even after damage to the protective layer, moisture penetration inside is limited;

- Preserves the elasticity of wood and reduces the risk of drying out;

- Prevents the development of mold and pathogens;

- Protect the tree from waterlogging.

In addition to vegetable oils and waxes, the composition includes water-repellent additives. Processing allows you to enhance the natural color of wood or give it a light shade with the addition of pigments.

Features of the use of waxed products

With all the advantages of the method of treating wood with liquid wax, it should be remembered that wax is a material sensitive to high temperatures. Under their influence he “floats”. Therefore, you need to take into account the features of the room in which future furniture or wood products will be used. Although the heat resistance of some modern industrial samples of liquid wax reaches 100 0C. However, you should not wax your kitchen work surfaces. If you accidentally spill hot food or place heated dishes, traces will remain. Which can only be removed by repeated waxing.

Wax is not compatible with products containing alcohol. When choosing a care product for waxed furniture, you should carefully read the composition and instructions. In general, it is enough to simply wipe it with a dry soft cloth, and to remove dirt or remove fingerprints from time to time use special cleaners with the obligatory mark “for waxed surfaces.”

Subject to application technology and proper care, coating wood products with liquid wax will ensure a long service life and a noble appearance.

Where can I buy

You can buy wood care products at almost any hardware store. But if the desired color or type is not available, then you should look for a suitable option in the online store.

In the case when the user is interested in a specific product, using filters and a search engine, you can quickly find the desired product.

If the buyer is not yet sure of the choice, then it is worth familiarizing yourself with the new products in this section, studying reviews from other buyers and viewing the entire recommended range. Search filters will help you quickly find the right product by price (lowest or most expensive), manufacturer, and also for what area of application.

Each product has a detailed description of its characteristics, which can be found on the website. After studying them in detail and making a choice, the buyer places an order online and waits for delivery of the purchased product.