Exotic tree species are attractive, but not very common due to the high cost of this wood. However, now there are many offers on the market not only for furniture made from exotic trees, but also for parquet and interior items. After all, these trees have a wide range of colors and allow you to realize many ideas.

Red tree

(mahogany, macaret, moving, belinga and others) are species that produce red wood of various shades. The most famous breed is mahogany, which is especially distinguished by its beauty and color. This is a sound disseminated-vascular deciduous species. It has narrow white sapwood and a brownish-red to red-brown heartwood. It has a characteristic ribbon texture in the form of stripes of dark brown color and light shiny stripes with a red tint, therefore it is widely used in the manufacture of high-quality furniture. Mahogany wood is of medium hardness and density, almost does not crack or warp. When freshly cut, mahogany wood has a yellowish-red color, but over time, under the influence of air and light, it darkens, gradually taking on a brown-red or crimson-red color with clearly visible light and dark veins. There are different types of mahogany: smooth, striped, patterned, flamed, speckled, knotted, etc.

The wood is well cut, processed and finished. The wood is not very durable; there are often chips and zigzag cracks in the transverse direction, which are difficult to detect due to their often small size. However, any transverse cracks mean that there is a complete rupture of the fibers and all strength is lost, which is why they are very dangerous.

Exotic woods

Currently, many well-known manufacturers of acoustic and electric guitars, such as Martin, Taylor, Takamine, Charvel, Suhr, Paul Reed Smith, and sometimes even Ibanez, Jackson, Fender and Gibson, in addition to using wood classic in the music business - maple, spruce, poplar, linden, alder, ash, mahogany, rosewood and ebony - exotic varieties of hardwood have increasingly begun to be used, in particular, corina, koa, pao ferro, cocobolo, walnut, wenge, lacewood, Spanish cedar, etc. We decided to look into this issue and collected all the available information in this article.

Let's start our story in order. In domestic literature, wood is classified into coniferous and deciduous, while in Western literature the terms softwood and hardwood are used, which are generally similar. Deciduous trees can grow in ordinary and tropical conditions: in the first case, the tree expands over the seasons and forms annual rings with radial (annular) porosity (for example, maple); in the second case, due to the constant hot climate, the trunk increases in size continuously, due to which growth rings are usually absent, and the porosity has a diffusion (uniformly dispersed) structure (for example, ebony). Sometimes there are also diagonal, chain, cluster and other types of pore arrangement. On guitars with a clear finish, you can usually easily tell the age of the body by looking at the growth rings if you look at the side from the bottom of the strap button.

The pores on the end grain (English: endgrain) are dissected vessels through which the trunk was fed from the roots to the crown. The larger the pore diameter (fractions of a millimeter) and the more often they occur per unit area, the lower the mass of the workpiece, all other things being equal. In the transverse direction, small capillaries extend from the vessels, in which useful substances accumulate inside the trunk, as well as long rays for feeding fresh wood on the periphery, which can be seen on some guitars.

Fresh, newly grown wood is sapwood and is usually white in color, sharply different in appearance and mechanical properties from the core of the trunk. Typically, sapwood is not used in the manufacture of musical instruments, although some manufacturers, such as Suhr, have glued sapwood tops to their guitars.

The weight of wood used in the production of bodies and necks depends on factors such as the climatic conditions of the tree's growth, the height of the cut along the trunk relative to the root, and the amount of moisture remaining inside the pores. To remove the latter, natural drying is used (English: natural, air drying), in which boards with pre-waxed ends lie in a warehouse for 6 months - 2 years, which is not economically feasible, and industrial drying (English: kiln drying), when evaporation moisture occurs in ovens within a few hours. There are vacuum, electric, convective, gas and other industrial drying technologies. In the guitar industry, the manufacturers we know of, Gibson and Suhr, use vacuum drying.

If the wrong technology is used, stresses arise in the wood, which cause internal or external cracks in the workpiece, after which it becomes unsuitable for the production of musical instruments. On the other hand, when using under-dried samples, there is a high risk of deformation of the neck under the tension of the strings. It should be noted that natural drying leaves an average of 10-20% moisture in the pores, while industrial drying leaves 5-15%, due to which thermally treated workpieces usually weigh lighter than the former.

Returning to climatic conditions, it is worth noting that wood, identical in name, depending on the continent of growth (Africa, Asia, America) has different porous structure, density, hardness, appearance and acoustic properties. Living examples are Madagascar, Indian, Brazilian, Mexican (bocot), Bolivian (pao ferro, santos) and other types of rosewood.

By density, wood can be divided into three categories: light (less than 500 kg/m3 - spruce, poplar, linden, alder, Pacific mahogany, coniferous and Spanish cedar, chestnut, Gabon, sequoia), medium (500-800 kg/m3 - maple, ash, Honduran and African mahogany, corina, koa, lacewood, walnut, paduk) and heavy (over 800 kg/m3 - rosewood, cocobolo, wenge, bubinga, ebony and many other exotic species). The hardness of a wood surface is usually directly proportional to its density.

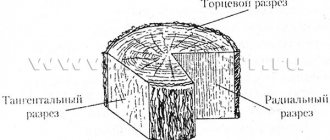

Wood cutting can be radial (English: quartersawn, radialsawn), rustic/semi-radial/mixed (English: riftsawn, transversesawn) and tagnetsial (English: flatsawn, plainsawn). In the first case, the growth rings are perpendicular to the surface of the end cut and parallel to the longitudinal plane, in the second, they run at a slight angle in the transverse direction and are not always symmetrical in the longitudinal direction, in the third, they are correspondingly close to parallel and form ring patterns from the earliest growth rings.

Rice. 1. “Options for cutting wood”

The most expensive is the radial cut due to its presentable appearance, the greatest mechanical strength and the maximum speed of sound transmission, as a result of which the necks of musical instruments are often made from it. In turn, when using radially sawn necks that have a high resonant frequency, it is advisable to select soundboards from tangential blanks, since they have a lower resonant frequency and a lower sound when overloaded.

As our experience shows, the sound of a guitar when overloaded also largely depends on the weight of the body. Thus, when using heavy blanks that ring when tapped, the instruments do not have sufficient density when playing riffs. On the contrary, lightweight blanks have a dull timbre, resonate better at low frequencies and are distinguished by wall-breaking overload. Of course, there are exceptions to the general rule, but in general the described pattern is observed.

A striking example of this fact is the solid body reissues of Gibson Les Paul Standard Reissue 1957-1960, which weigh 3.6 - 4 kg and sound an order of magnitude more powerful than heavy Gibson Les Paul Custom weighing 4 - 5 kg regardless depending on the year of manufacture and the presence or absence of 9 holes (not counting the reissue of 1957 Black Beauty). In turn, for fretboards, preference will be given to heavy and hard wood species that give a bright attacking sound (for example, ebony, pao ferro or bird's eye maple, obtained from the butt or burl part of a mountain maple).

It is important to note that the small weight of the instrument can be due to the use of thin bodies (English slim body) or internal perforation (English weight relief), which many custom shop manufacturers usually keep silent about, positioning their guitars as solid-body from premium grades of mahogany, which not true.

In particular, the use of perforated soundboard under the maple top is hidden by Dean Thoroughbred (5 cavities - 4.2 kg), PRS SC 250 (8 cutouts - 4.2 kg), McInturff Taurus (16 cutouts - 4 kg), PRS 513 (7 cutouts - 3.8 kg), Kauer Starliner (10 holes - 3.8 kg), CPThornton Legend (4 holes - 3.8 kg), McInturff Empress (1 cavity - 3.7 kg), Collings CL Deluxe (18 holes - 3.7 kg), Grosh Set Neck (5 holes - 3.6 kg), J Nunis Standard SC (17 holes - 3.6 kg), b3 Fire SL (11 holes - 3.5 kg), Gustavsson Bluesmaster Custom ( 7 cavity - 3.5 kg), Bruno Urban LP Junior (2 large cavity - 3.5 kg), and Guild Bluesbird (3.6 kg) and PRS Limited Edition 1990 (3 kg) have a hollow body.

At the same time, PRS Singlecut (4.1 kg), McNaught Vintage SC (4 kg), Gene Baker LP (4 kg), Hufschmid Tele (3.9 kg), PRS Stripped 58 (3.7 kg), PRS Santana II-III (3.6-3.7 kg), Ruokangas Unicorn Classic (3.6 kg), Fano Alt De Facto TC6 Custom (3.6 kg), Paoletti Flying Eagle (3.5 kg), McInturff Monarch ( 3.5 kg), McInturff Polaris (3.4 kg), Knaggs Kenai (3.4 kg), PRS P22 (3.4 kg), PRS McCarty Mahogany (3.3 kg), Warrior Bella (3.3 kg ), the Warrior Gabriel (3.2 kg) and DBZ Royale (2.9 kg) use classic bodies, and Gibson is honest about the use of different geometries to lighten the bodies in production versions of the Les Paul, with the most expensive reissues being the 1959-1960 Reissue Brazilian Rosewood (3.6 - 3.9 kg) made from a thick solid piece of Pacific mahogany and Brazilian rosewood fingerboards costing $10,000-15,000 leaves behind all other manufacturers both in weight and sound.

Rice. 2. “Examples of internal perforation (cutouts, holes, cavities, hollow body)”

Rice. 3 "Gibson Chet Atkins Solid Body Electro Acoustic"

Another feature of the new instruments that is worth mentioning is their weak resonance and rapid damping of vibrations until the guitar plays, which usually takes 2 to 4 weeks of active use. This is most likely due to the presence of resin particles in the wood pores of conifers, which dampens sound waves and dampens sustain. Over time, the resin is distributed within the pores in such a way that it no longer interferes with the vibrations of the guitar and gradually hardens, after which it reveals its full potential. Regarding deciduous species, this question remains open. The Hawaiian Koa and Makassar Ebony take a particularly long time to develop, as they take longer to acquire rich overtones than other breeds. Thus, the sound of wood should only be assessed on time-tested instruments.

It is important to note that listening to electric guitars should be done in a connected state through a tube amplifier at a concert volume, since the acoustic characteristics when played without a connection do not always correlate with the electric sound (for example, due to the presence of internal cavities).

In our opinion, the best musical species that give the most luscious overtones when playing solo, in addition to traditional mahogany and ebony, are Brazilian rosewood, Hawaiian koa, Amazonian granadillo, bubinga and wenge. A clear confirmation of this fact is the limited edition products of Gibson Custom Shop & Historic Reissue and Paul Reed Smith Private Stock & Wood Library.

At the same time, it should be borne in mind that when several different types of wood are glued together in a “sandwich”, the character of the guitar will differ from the description of each of them separately due to changes in the amplitude-frequency characteristics and the resonant frequency of the structure. For example, if you use a mahogany body with a maple top, the sound of the instrument will not be as dense as on a mahogany soundboard without a top, but also not as bright and sharp as is inherent in maple, having come to a certain compromise.

As for the use of wood in various parts of the guitar, the following pattern is observed here - the neck of the instrument is responsible for the attack, the pickguard is for readability, the body provides a dense low end and a bold middle, and the top provides bright highs. At the same time, all of the listed components are involved in the formation of rich overtones and long sustain, including the precision of milling and the cleanliness of grinding of the mating surfaces, the quality of their gluing, as well as the thickness and type of primer and varnish (nitrocellulose, polyurethane, polyester, acrylic) or other coating (oil, wax).

If we talk about the design of the instrument, then the main difference between screwed and glued necks, all other things being equal, is the amount of sustain, while through-the-stick “sticks” sound completely different, characterized by a fat and blurry attack on riffs (as if they had switched on a neck instead of a bridge pickup) and smooth compressed notes on solos. It’s worth noting right away that this does not include most modern Jacksons with a pseudo-through neck, which is glued into the body to a shallow depth and cut off at the neck pickup. Also, contrary to popular belief, a high-quality, unworn tremolo does not eat up the sustain of the instrument.

Of course, the sound of an electric guitar is greatly influenced by properly selected pickups, the frequency response of which should correlate with the characteristics of a particular wood. For example, for a body made of swamp ash, maple or lacewood, the right choice would be pickups with a voluminous low end and a dense midrange coupled with smooth highs, while when using Pacific mahogany, corina or Spanish cedar, pickups with a flat low end, a trimmed midrange and bright ones would be optimal. on top. Otherwise, the sound at some frequencies will be too boosted, and at others it will fail, which will lead to an unbalanced sound of the instrument. In our opinion, pickups contribute up to 50% of the overall picture to the perception of an electric guitar.

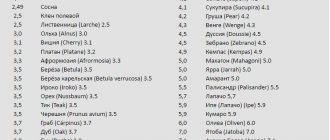

Below is a table that includes five groups of more than 70 exotic tree species:

1) mahogany and analogues - Honduras, Pacific, Philippine (meranti) and African (kaya) mahogany, sapele, Gabon, cosipo, merbau, makor (African cherry), yarra (eucalyptus), korina (limba, ofram), Spanish cedar , chestnut, poplar, linden, primavera, avodir, cherry;

2) rosewood and analogues - Madagascar, Indian, Brazilian, Mexican (Bocot), Bolivian (Pao Ferro, Santos), Caribbean (Chechen), Indonesian (Borneo, Rengas), Panamanian (Yucatan), Amazonian, Burmese, Guatemalan, Honduran , Cambodian rosewood, bois de rose, cocobolo, granadillo (hormigo, macacauba), ovangkol, voamboana, palo escrito;

3) ebony and analogues - African, Indian, Macassar, brown, moon and white (persimmon) ebony;

4) nuts and analogues - American, English, Peruvian, Brazilian (imbaya), New Guinea (paldao) and Caribbean (tzalam) nuts;

5) other exotic species - koa (acacia), sequoia, lacewood, abacha (African white tree), horse chestnut, mango, myrtle (pepper tree), Afromosia (African teak), madrone, canary (Arariba), gonzalo Alves (tiger wood), wenge, padauk, bubinga, amaranth, black (Tasmanian) sassafras, Australian (Tasmanian) ebony, ziricot, zebrawood, snakewood, bloodwood (satin), ironwood and kingwood.

Some of the listed exotic species, such as Pacific mahogany, corina, Spanish cedar, chestnut, Indian and Brazilian rosewood, granadillo, cocobolo, pao ferro, wenge, bubinga, padauk, lacewood, koa, walnut and sequoia, were listened to by us live, so the description written in the first person. The sound of other species, average density (at 12% humidity) and hardness, as well as all photographs are taken from open sources (for example, from the ESP website), including from international suppliers of guitar wood.

It is also interesting to note that the scientific and trade names of most of the wood species discussed are different. When writing this article, we were guided by generally accepted (trade) designations.

| Wood | Photo | Continent | Density | Hardness | Description | |

| MAHOGANY AND ANALOGUES | ||||||

| Honduran Mahogany | Central and South America | 500 - 600 kg/m3 | 4020 N | Gibson used lightweight blanks from selected (genuine) Honduran mahogany for the release of the Les Paul model from 1952-1960. Then, what is considered standard today, made from heavier wood, similar in weight to African mahogany, went into production. | ||

| Pacific Mahogany | Fiji | 450 – 500 kg/m3 | Currently, when releasing reissues of Gibson Les Paul Standard Reissue 1957-1960, a very rare and expensive variety of mahogany native to the island of Fiji in the Pacific Ocean is used, which is similar in weight and acoustic characteristics to selected Honduran mahogany. Thanks to its lightweight mass, the wood resonates perfectly and has a wall-breaking overload. | |||

| Philippine Mahogany (Meranti) | Philippines | 480 – 680 kg/m3 | 2460 - 4670 N | There are light red, yellow, white and dark red meranti with increasing density and hardness in the indicated sequence, which are considered Philippine mahogany. | ||

| African Mahogany (Kaya) | West Africa | 600 – 650 kg/m3 | 4760 N | Kaya is an African analogue of modern Honduran mahogany, similar in mass and acoustic properties. The remaining varieties of mahogany from Africa do not formally belong to mahogany, but their characteristics are identical to it. | ||

| Gabon | Central Africa | 430 kg/m3 | 1790 N | Gabon is the lightest African mahogany. | ||

| Sapele | West Africa | 650 – 700 kg/m3 | 6280 N | Sapele is a heavy analogue of kaya and has an edgier sound when overdriven. | ||

| Kosipo | West and Central Africa | 640 kg/m3 | 5260 N | Kosipo is another variety of African mahogany. | ||

| Makor (African cherry) | West and Central Africa | 650 – 700 kg/m3 | 5350 N | Makor is another variety of African mahogany. | ||

| Merbau | East Africa, Malaysia and Indonesia, Australia and New Guinea | 800 – 850 kg/m3 | 7620 N | Merbau is a heavy mahogany variety native to several continents. | ||

| Yarra (Eucalyptus) | Western Australia | 800 – 850 kg/m3 | 8270 N | Yarra is an Australian eucalyptus tree that has a higher density and hardness than African mahogany varieties. | ||

| Corina (Libma, Ofram) | West Africa | 500 – 550 kg/m3 | 2990 N | Korina is the African equivalent of mahogany. Depending on the appearance, it is divided into white and black - the first represents the high and peripheral sections of the trunk, while the second represents its core and butt part. Corina is generally lighter than modern Honduran and African mahogany, with a tighter midrange and better resonance. Many Gibson guitars, such as the Les Paul, Explorer and Flying V, were made from corina. This wood is also used to a limited extent by Jackson, Suhr, Paul Reed Smith, Hamer, Washburn, Warmoth, Kiesel, Knaggs, Mayones, Reverend, Witkowski, McInturff, McNaught, Bruno Urban, b3 Guitars, Shamray, Lepsky, Padalka, Poznysh and Vaschenko. | ||

| Spanish cedar | Central and South America, Caribbean | 470 kg/m3 | 2670 N | Spanish cedar is not related to conifers and is an American analogue of selected Honduran and Pacific mahogany, as well as light corina. The mass of wood is very small, and the sound of the guitar when overdriven is similar to the Gibson Les Paul R7-R0 reissues. Spanish cedar is used by many Custom Shop manufacturers such as Ruokangas, Dommenget, Kauer, McInturff and Suhr. | ||

| Chestnut | Eastern America | 480 kg/m3 | 2400 N | Chestnut is an analogue of selected Honduran mahogany, corina and Spanish cedar, having a low weight and a powerful sound when overloaded. Italian manufacturer Paoletti uses chestnut from 150-year-old wine barrels to create Custom Shop guitars. | ||

| Poplar | North America | 455 kg/m3 | 2400 N | American poplar is a lightweight analogue of mahogany, popularized by manufacturers such as Jackson. From 1983 to 1997, American Randy Rhoads and Kelly models were made from poplar, then Japanese guitars until 2000. Poplar is currently used by Music Man. The wood is characterized by light weight and has a hammer-like bottom coupled with a dense middle and the absence of pronounced high frequencies. | ||

| Linden | North America | 415 kg/m3 | 1820 N | American linden is a lightweight analogue of mahogany, introduced into circulation by such manufacturers as Ibanez. Currently it is also used by the Music Man factory. The sound of wood is characterized by a dense middle with the absence of pronounced high and low frequencies. | ||

| Primavera | Central America | 465 kg/m3 | 3170 N | According to the description, primavera, sometimes called white mahogany, has bright highs, clear mids, voluminous lows and is used to a limited extent for the production of basses, acoustic and electric guitars. | ||

| Avodir | West and Central Africa | 575 kg/m3 | 5180 N | According to the description, avodir is close in sound to African mahogany, black corina and American cherry. | ||

| Cherry | North America | 560 kg/m3 | 4230 N | Cherry is described as having a similar sound to mahogany, having a rich midrange with a clean high end, and is used by Martin in making acoustic guitars. | ||

| ROSE TREE AND ANALOGUES | ||||||

| Madagascar rosewood | Madagascar | 930 – 950 kg/m3 | 11360 N | Madagascar rosewood is an African variety of rosewood and has a fat, compressed sound with muted highs. | ||

| Indian rosewood | India | 830 – 870 kg/m3 | 10870 N | Indian rosewood differs from African rosewood in its sharp attack with bright sparkling tops while maintaining a bold sound. Installed on Gibson Les Paul R7-R0 reissues and many premium guitars from other brands, such as Paul Reed Smith, McNaught, McInturff, Ruokangas, Suhr, etc. | ||

| Brazilian rosewood | Brazil | 830 – 850 kg/m3 | 12410 N | Brazilian rosewood, in addition to the characteristics of Indian rosewood, has a sharper upper midrange and the richest overtones, comparable to the sound of koa and granadillo. Used in limited editions on Gibson Les Paul Reissues of various years in 2001 - 2003. Also, Brazilian rosewood is used to a limited extent by Suhr, Paul Reed Smith, Martin, McNaught, Gustavsson, Nunis, etc. | ||

| Mexican rosewood (Bocott) | South America | 800 – 1000 kg/m3 | 8950 N | Bocotte, also called Mexican rosewood, is described as having a bright attack and excellent sustain. Some manufacturers, such as Suhr, use bocotte to produce necks and fingerboards. | ||

| Bolivian Rosewood (Pao Ferro, Santos) | South America | 860 – 870 kg/m3 | 8710 N | Pao Ferro, also called Bolivian Rosewood, has a very sharp attack, bright highs, a bold compressed base tone and a tight low end. Some manufacturers, such as Suhr, use pao ferro as an alternative to maple in their necks and fingerboards. | ||

| Caribbean Rosewood (Chechen) | Central America | 990 kg/m3 | 10010 N | Caribbean rosewood is used extremely rarely by boutique guitar makers such as Ken Lawrence, as well as on acoustic guitars. | ||

| Indonesian rosewood (Borneo, Rengas) | Indonesia | 765 kg/m3 | 8710 N | According to the description, Indonesian rosewood is close in sound to Indian rosewood. | ||

| Panamanian (Yucatan) rosewood | Central and South America | 680 kg/m3 | 5400 N | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. Sometimes referred to as granadillo. | ||

| Amazonian rosewood | Central and South America | 1085 kg/m3 | 11990 N | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||

| Burmese rosewood | Southeast Asia | 940 kg/m3 | 12060 N | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||

| Guatemalan rosewood | Central America | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||||

| Honduran rosewood | South America | 1025 kg/m3 | 9790 N | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||

| Cambodian rosewood | Southeast Asia | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||||

| Boys de Rose | Madagascar | 930 kg/m3 | 11570 N | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||

| Cocobolo | Central and South America | 900 – 1200 kg/m3 | 14140 N | Cocobolo has a sharp attack coupled with rich overtones. Manufacturers such as Suhr use cocobolo for necks, fingerboards and tops, while Paul Reed Smith, Taylor and Takamine use it for acoustic guitar bodies. | ||

| Granadillo (hormigo, macacauba) | Central and South America | 950 kg/m3 | 12030 N | Granadillo, also called hormigo and macacauba, is close in sound to Indian and Brazilian rosewood, possessing a sharp attack, bright sparkling tops and fat, juicy overtones with a bell-like sound. Granadillo fretboards have been used on Gary Moore's Gibson Les Pauls and many Ken Lawrence instruments, and Taylor and Paul Reed Smith make acoustic guitar bodies from it. | ||

| Ovangkol | West Africa | 820 – 850 kg/m3 | 5900 N | According to the description, ovangkol has a slightly fatter middle and sharper tops compared to classic rosewood. Manufacturers such as Taylor and Takamine use Ovangkol to make cabinets. | ||

| Voamboana | Madagascar | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||||

| Palo Escrito | South America | Used by some Custom Shop manufacturers to produce acoustic and electric guitars. | ||||

| EBLOG AND ANALOGUES | ||||||

| African ebony | West Africa | 950 – 1050 kg/m3 | 13700 N | Ebony is a completely black wood, combining the attack and clarity of maple with the fat and rich sound of rosewood. | ||

| Indian ebony | Southeast Asia | 900 – 950 kg/m3 | 10790 N | Indian ebony has brown veins in the wood. | ||

| Makassar ebony | Indonesia | 1000 – 1100 kg/m3 | 14140 N | Makassar ebony is distinguished by significant light brown stripes and a clipped center. Limited use by manufacturers such as Suhr, Paul Reed Smith and Takamine. | ||

| Brown ebony | South America | 1160 kg/m3 | 15970 N | Brown ebony is an American variety of ebony, similar to rosewood. | ||

| Lunar ebony | Southeast Asia | 800 – 850 kg/m3 | 7920 N | Moon ebony is a light wood with black veins. | ||

| White ebony (Persimmon) | North America | 835 kg/m3 | 10230 N | White ebony (persimmon) is called persimmon in English literature and is used by some Custom Shop manufacturers for acoustic guitar bodies. | ||

| NUT AND ANALOGUES | ||||||

| American walnut | North America | 600 – 750 kg/m3 | 4250 - 5560 N | American walnut has several varieties (Black, Claro, Bastogne in order of increasing density and hardness) and is characterized by a warm, thick sound with a rich midrange and good highs, in terms of frequency balance being between mahogany and rosewood. Firms like Ibanez and Gibson used it to rebond 3-piece maple necks. In addition, Gibson and Hufschmid occasionally use walnut as tops, and Taylor for bodies. | ||

| English walnut | Eastern Europe and Western Asia | 640 kg/m3 | 5410 N | English walnut is the European equivalent of American walnut. | ||

| Peruvian walnut | Central and South America | 600 kg/m3 | 4250 N | According to the description, the sound of the Peruvian walnut is generally similar to the American one. | ||

| Brazil nut (Imbaya) | Brazil | 660 kg/m3 | 4300 N | According to the description, imbaya sounds like a nut. On request, Warmoth produces vultures from imbaya. | ||

| New Guinea nut (Paldao) | Southeast Asia | 670 kg/m3 | 4640 N | According to the description, paldao has a bright sound similar to bocotta. | ||

| Caribbean nut (Tzalam) | Central America | 780 kg/m3 | 6230 N | Tzalam is used by some Custom Shop manufacturers in the production of acoustic and electric guitars. | ||

| OTHER EXOTIC BREEDS | ||||||

| Koa (Acacia) | Hawaii | 600 kg/m3 | 5180 N | Koa is the national wood of Hawaii, along with Brazilian rosewood and granadillo, which has the richest overtones when played solo. At the same time, the riffs are no different from guitars made from classic woods. Manufacturers such as Kramer, Charvel, Carvin, Suhr, Roman, Martin and Taylor used Koa for their bodies, while Gibson, Fender, Jackson, Ibanez, Hamer, Paul Reed Smith, Music Man, ESP, Washburn, Warmoth, McNaught, Mayones, Collings, Kiesel, Hufschmid, Ken Lawrence, Tom Anderson, McPherson, Goodall, Melancon, Shamray, Lepsky and Padalka produce limited edition tops only. | ||

| Sequoia | North America | 410 – 420 kg/m3 | 2000 N | Sequoia belongs to the coniferous species and is called redwood in Western literature, distinguished by a very sharp and harsh sound. Sequoia tops are used in limited quantities by manufacturers such as Jackson, Paul Reed Smith and Taylor. | ||

| Lacewood | Northern Australia | 530 – 580 kg/m3 | 3160 N | Lacewood is Australia's national wood with a distinctive lacy grain pattern and has a sharp, readable tone with a reasonable low end. Lacewood bodies were used to a limited extent by Charvel and Jackson, and Ibanez tops. | ||

| Abacha (African Whitewood) | West Africa | 380-390 kg/m3 | 1910 N | Abacha, called obeche in Western literature, was used to a limited extent by Gibson as fingerboards. | ||

| horse chestnut | North America | 400 kg/m3 | 1560 N | The butt part of the horse chestnut, called buckeye in Western literature, is used by Suhr and some Custom Shop manufacturers as guitar tops. | ||

| Mango | Tropical Asia and Oceania | 675 kg/m3 | 4780 N | Mango is described as having a koa-like sound and is used to a limited extent by Paul Reed Smith as guitar tops. | ||

| Myrtle (Pepper tree) | North America | 635 kg/m3 | 5650 N | According to the description, myrtle is similar to maple, having a clear and bright sound. | ||

| Afromosia (African teak) | West and Central Africa | 700 – 750 kg/m3 | 6980 N | According to the description, Afromosia has a bright attack, excellent sustain and a sound similar to maple. On request, Warmoth produces vultures from Afromosia. | ||

| Madron | North America | 800 kg/m3 | 6490 N | Paul Reed Smith is used to a limited extent as guitar tops. | ||

| Canary Islands (Arariba) | South America | 830 kg/m3 | 6750 N | According to the description, canary has a bright sound, similar to maple. On request, Warmoth produces vultures from canary wood. | ||

| Gonzalo Alves (Tiger Tree) | South America | 900 kg/m3 | 9640 N | According to the description of Gonzalo Alves, also called tigerwood, it has a balanced warm timbre with good readability. On request, Warmoth produces necks from Gonzalo Alves. | ||

| Wenge | Central Africa | 850 – 900 kg/m3 | 8600 N | The sound of wenge is similar to walnut, having a dense low end and a fat middle, but distinguished by bright highs and very juicy overtones. This wood is used for the production of necks and fingerboards by such manufacturers as Paul Reed Smith, Rickenbacker, Warmoth, Mayones, Collings, Kauer and Universum. | ||

| Paduc | Central and Western Africa | 750 - 800 kg/m3 | 8760 N | Paduk has a bright attack, a sharp midrange, good overtones and a sound similar to maple. Warmoth makes padauk necks and bodies to order, Mayones uses it for lamination, and Washburn makes N4 guitars. | ||

| Bubinga | Central Africa | 800 – 950 kg/m3 | 10720 N | Bubinga has a deep low end, a tight midrange, a sharp attack and very rich overtones with excellent sustain. Warmoth makes custom necks and bodies from bubinga, Bruno Urban makes necks only, Mayones uses it for lamination, and Ken Lawrence makes tops. | ||

| Amaranth | Central and South America | 850 – 900 kg/m3 | 11190 N | According to the description, amaranth, called purpleheart in English literature, is similar in sound to bubinga, having a deep bottom and excellent sustain. On request, Warmoth produces necks from amaranth, and Mayones uses it for lamination. | ||

| Black (Tasmanian) sassafras | Australia | 600 – 650 kg/m3 | 4860 N | According to the description, black sassafras is a unique sounding wood, including volume at the bottom, bright tops, high readability and can sound like woods such as mahogany, rosewood, maple or walnut depending on the playing style of the musician. Used by Taylor to make cabinets. | ||

| Australian (Tasmanian) ebony | Australia | 600 – 650 kg/m3 | 5180 N | Australian Ebony is described as looking and sounding similar to Koa, having a rich, juicy midrange and bright highs. Taylor is used for the manufacture of cases. | ||

| Zirikot | Central America | 800 – 900 kg/m3 | 8780 N | According to the description, Zirikot has a pleasant midrange and excellent sustain. Used by Suhr and Paul Reed Smith as tops. | ||

| zebra tree | West and Central Africa | 750 - 800 kg/m3 | 8160 N | According to the description, the zebra tree, called zebrawood in English literature, is similar in sound to maple. Suhr and Paul Reed Smith are used to produce tops. | ||

| Bloody Tree (Satin) | South America | 1000 – 1100 kg/m3 | 12900 N | According to the description, the bloody tree, called bloodwood in English literature, has bright tops and a very long sustain. On request, Warmoth produces necks from satin. | ||

| snake tree | South America | 1200 – 1300 kg/m3 | 16900 N | The snake tree, called snakewood in English literature, is one of the hardest, heaviest and most unusually beautiful. Used extremely rarely on exotic guitars. | ||

| iron tree | Southwest America, Central America and the Caribbean | 1200 – 1400 kg/m3 | 14500 – 16280 N | Ironwood, called ironwood in English literature, is one of the hardest and heaviest in guitar making. It is divided into desert and black in order of increasing density and hardness. Gibson has had limited use as fingerboards. | ||

| Royal tree | Brazil | 1200 kg/m3 | 17240 N | According to the description, the royal tree, called kingwood in English literature, has a fast attack, excellent readability and long sustain. Used by Suhr as tops. | ||

Vlad X worked on this article

Bamboo

Bamboo is not technically a tree. It belongs to the grass family, and its tree-like tubular stem is a woody straw, reaching 40 m in height and 30 cm in diameter in some species.

The natural color of bamboo is golden straw, alternating with darker transverse stripes at the locations of the stem nodes. The structure is homogeneous and dense. The structural features of bamboo do not allow it to be used in its natural form for the manufacture of massive products. Therefore, bamboo parquet planks are glued together at the factory from separate strips.

Bamboo is well resistant to mechanical and climatic influences. When grinding, it requires the correct selection of abrasive materials and the sequence of their use.

Lemon Tree

A species with hard and brittle wood of a yellowish-golden color with an expressive ribbon texture and shiny spots caused by the curling of the fibers; Because citron has "bee's wing" markings, it is an extremely decorative wood that has been used for centuries in the creation of high-value furniture. The wood is very difficult to work due to its specific growth structure, tools become dull due to the great hardness of this wood. Citron dries slowly and should not be exposed to sun or drafts. There is a tendency to check and deform. It is difficult to cut; contains essential oils, which must be taken into account when finishing.

Bubinga

This tree is native to equatorial Africa. The density of wood is about 900 kg/m³. The core part is very hard and dense, distinguished by a red-brown tint with dark veins. Freshly cut plants have a characteristic, not very pleasant odor, which completely disappears during drying.

Bubinga is used to produce furniture elements, parquet and flooring. The trunk is often used to create countertops. Bubinga is often used in the manufacture of musical instruments: harps, drums, bass guitars. Less commonly, wood is in demand when finishing the interior of expensive cars.

Hornbeam

Hornbeam is also called white beech. It has a hard, durable and dense wood with a whitish-gray color. The texture of hornbeam is not bright, like, for example, ash; Light dots are scattered on the evenly matte background of its wood. Often this species has a cross-layered wood structure, so the hornbeam is difficult to split. The sapwood does not make much difference in the transition to the heartwood. To avoid deformation and cracking, it requires long and careful drying.

After drying, the hornbeam is almost not subject to warping; its hardness becomes higher than oak. It is difficult to handle with cutting tools. The use of hornbeam in carpentry is varied, although not as widespread as oak, ash or beech; used in mosaic making. The hornbeam is well finished and poisoned.

Ipe

Widely used wood for flooring for various purposes, from home parquet to deck flooring.

A very durable rock that is practically not susceptible to moisture felting and can easily transfer significant loads to the surface. The disadvantage of Ipe is that it is very difficult to saw, but it is easily polished to a glossy shine and does not lose its characteristics over time.

Externally, Ipe looks very colorful and expressive. A shift in color from bright yellow to dark brown is the norm and this feature should be taken into account when purchasing a product.

Paduc

Widely known in professional circles due to its features, which make it possible to use it both in the creation of floor coverings and in the manufacture of decorative products of varying degrees of complexity.

Paduk is easy to process and polish, and does not deform when dried. It can often be found in furniture production, as well as in the manufacture of premium parquet, where most often not the wood itself is used, but only its veneer.

Yew

Yew is one of the rarest species. The breed is sound, with narrow yellowish-white sapwood and a red-brown heartwood. When exposed to water, it changes its color to purple-crimson. It differs from other rocks by the sinuous boundaries of annual rings of varying thicknesses, which stand out clearly in all sections. The texture is very expressive and decorative, especially on bevel sections. The wood is dense, hard, but fragile, has a low shine, and is exceptionally durable (the wood does not rot, it is viscous). It is well processed, cut, sharpened and finished.

Sequoia

The species is coniferous, soundwood, the sapwood is narrow, white. The color of the core varies from light red to brownish-red, often in violet tones and darkens over time, the growth rings are clearly visible, in terms of physical and mechanical properties it is close to spruce wood, it is resistant to decay and hardness. Redwood is one of the best commercial woods in the world because it is free from knots. Easily processed by hand and machines. Drying must be done carefully due to the high moisture content. Wood used for external purposes must be protected from weather influences.

Distinctive properties of valuable tree species

People have special requirements for these types of wood:

- beauty, expressiveness of texture and color;

- strength, hardness;

- resistance to mechanical loads;

- resistance to decay;

- durability;

- the ability to withstand fluctuations in humidity and temperature without loss of properties.

Valuable wood species have a high cost; they are usually used for the manufacture of expensive products - furniture, interior items, parquet, window frames, doors. These products create a special atmosphere in the room, emphasizing the refined taste and high position of their owner.

Rosewood

The species is heartwood, the sapwood is narrow, light yellow in color with a grayish tint, the heartwood is purple-brown or chocolate-brown with black and dark-brown stripes and veins, the growth rings are hardly noticeable. Mature wood is very dark (dark brown) with lighter longitudinal veins, and may have a subtle purple or lilac tint. The cut shows the exits of numerous pores (channels) in the form of small black dots or dashes. The wood is very dense, difficult to cut, and contains essential oils that make finishing difficult; It gets darker over time.

Merbau

The main color of merbau is brown, from light to dark brown, interspersed with yellow streaks in places. The wood is very hard, resistant to moisture, and does not dry out much. This dense and non-siliceous wood is difficult to work with hand tools. Has a blunting effect on saw blades and other cutting and processing tools. Wood can sometimes ruin saw teeth. The wood glues and sands well. During use, merbau darkens (especially the lighter areas), as a result of which the color of the wood as a whole is evened out. Belongs to the least rotting wood species. Virtually immune to dry rot, subterranean termites and other insects or fungi. The yellow flavonols in the pores help make the wood resistant to insects and fungi, but are susceptible to dissolution in water and disappear in humid conditions.

Kempas

Sapwood and heartwood are very different from each other. The sapwood is about 5 cm thick, yellowish-white, the heartwood is initially light red and darkens over time to red-orange. The color of the wood is bright and immediately noticeable: from golden-reddish to dark orange. The structure is relatively uniform and dense. The texture when cut is relatively smooth, with lighter longitudinal veins.

It is characterized by high hardness and density; in favorable conditions (without access to moisture and with air exchange) it can be used for a very long time. Little resistant to moisture. In general, along the thickness of the trunk, the structure of the wood fibers is very heterogeneous, so when processed, the wood fluffs, but lends itself quite well to sanding and drilling.

Afromosia

Another African tree with a yellowish tint, and a structure reminiscent of beech or teak. Afromosia is relatively inexpensive, as compared to its closest neighbors Merbau and Tali, it has lower characteristics. In particular, Afromosia is afraid of moisture and can dry out upon contact with water, even for a very short time.

In addition, Afromosia wood cannot be used in conjunction with metal, as it can absorb rust from it and itself become a dirty brown shade, which is almost impossible to remove.

Despite this, Afromosia is often used for the production of floor coverings; it is carefully processed with special means.

Yarra

The wood is bright or dark red tones with an intricate textured pattern. The main quality is its very high density and hardness, which is why it is often used in industrial production and construction.

It is used to make piers and floors for objects with very high traffic. Yarra does not rot or be attacked by bugs, but there is one significant factor that greatly affects the cost of this material. Namely, the complexity of processing. The fact is that Yarra is very difficult to saw and can quickly dull saws.

Today, you can often find products with Yarra veneer, as they look very attractive and original.