Environmentally friendly and comfortable log houses are reliable buildings that will last for years. Wood creates that unique coziness that cannot be obtained from any other material. In addition, wood does not emit toxins, no matter what the temperature is outside or in the house.

It’s easier to breathe in a log house, even if it’s a very small one, and it’s more pleasant to be in than in an ordinary brick house. Such houses are chosen by fans of original interiors that will also be healthy. Each log house can be considered unique and one of a kind, since each log has its own pattern.

Another undoubted advantage of wooden houses is good heat and sound insulation. Silence and comfort are guaranteed to you. Thanks to special wood processing and some secrets in construction, the log house will serve you for decades.

Features of manual cutting

The technology for constructing log houses came to us from our ancestors. The main material here, of course, is tree trunks cut down and processed by hand. This approach can preserve all the beneficial qualities of wood. The result is an ideal material for construction, which has no analogues.

The peculiarity of chopped logs is the different diameter of the trunks and the uneven surface of the finished material. Of course, in this way it is impossible to create a perfectly even frame, as when using rounded wood. But you will get a house that will be different from other buildings of the same plan.

The technology of constructing a log house itself is laying logs on top of each other using logs or transverse logs. To ensure they fit tightly and with a minimum of cracks, a groove is cut in the bottom log, ideally oval. Sometimes a triangular one is used, but it does not provide such a reliable connection.

After installing the frame, the walls are caulked, since the grooves are not always smooth. This will ensure complete tightness, protection from cold and wind, and also prevent the appearance of cracks on the logs themselves. It is also possible to carry out other work on the surface. Among them are insulation, sanding, coated with protective or decorative agents. Thus, the result is to enhance the insulating properties of the log house and improve its appearance. The tree is completely protected from the influence of climate change, insects and fungus.

Which option is preferable for building a house?

If you look at the difference between a chopped log and a rounded one in terms of use for building a house, you need to proceed from your own goals. It is important for you to get housing quickly - choose processing on a machine, since “manual” log houses must withstand a shrinkage period of up to 8-12 months. You don’t have to figure out how to choose a rounded log - most manufacturers use standard machines, the building material is uniform.

Hand cutting is preferable if you want:

- get a house “for centuries”, built using traditional technology, impressive and monumental;

- immediately take care of the future - reduce upcoming energy costs, simplify home maintenance (logs will deteriorate much less);

- preserve the natural texture of wood and get the most environmentally friendly home, close to nature.

Difference between rounded and chopped logs

First of all, the method of processing materials differs. Chopped logs are always processed by hand. They turn out to be different in diameter, with irregularities. At the same time, during construction it is necessary to demonstrate a high level of skill in order to correctly execute the longitudinal groove. This type of work is trusted to professionals with extensive experience.

Rounding of logs is carried out using machines that give the wood the desired shape. As a result, the output is smooth logs of the same diameter. This characteristic makes it easier to lay the logs.

But rounding involves cutting off a fairly thick top layer. This significantly reduces the wood's environmental protection. At the same time, manual processing is carried out in a gentle way, so that the top layer remains practically untouched.

But despite the processing method, both materials require protective treatment with antiseptics, fire retardants and other special agents. Over time, any wood can rot, crack and lose its positive qualities. Antiseptic agents and impregnations help avoid this. Paints and varnishes are also used. In addition, fire retardants are used in the construction of log houses, which reliably protect against fire.

It must be borne in mind that no matter how the logs are processed, they in any case experience significant shrinkage. Already in the first year it will be about 10%. Therefore, it is worth postponing finishing and carrying out all kinds of communications for at least six months. Otherwise, you risk damaging the fresh frame, the tree will spread and the house will be warped.

From an aesthetic point of view, log houses can be considered more interesting and attractive. Naturalness and texture allow such a building to harmoniously fit into any landscape. This type of wood will appeal to those who appreciate the spirit of antiquity and want to bring it into their home. Rounded logs give a more laconic and aesthetic appearance. The neatness and perfect similarity of the material allows it to be used in any interior.

What you should pay attention to when choosing the diameter of a log

When choosing logs for a log house, pay attention to the climatic conditions of the region. In the southern regions, for the construction of seasonal housing, if it is very important to save money, you can even use a diameter of 20-22 cm. For a house with year-round living, it is advisable to use a diameter of 24-26 cm. For northern latitudes, a diameter of at least 26 cm is recommended, the average is 28-30 cm.

For the construction of a log house for a bathhouse, logs with a diameter of 22-24 cm are suitable as a minimum. But we still recommend taking at least 24 logs in diameter, with the average being around 26-28 cm. This allows you to heat the room regardless of the outside temperature and will prevent the room from freezing without warming up.

The thickness of the external walls depends on the design of the building. The building frame must withstand all loads. Another feature is the thermal conductivity of external walls. In cold weather there must be an economic balance in heating costs. The larger the diameter of the external walls, the lower the cost of heating the room.

ADVANTAGES OF CHOPPED LOG

- A completely safe and interesting material that can create a unique microclimate in the house;

- Significantly less cracking and practically does not absorb moisture;

- Preservation of the natural protective layer preserves such qualities of wood as resistance to ultraviolet radiation and insects;

- A massive log house is much more reliable due to the greater thickness of the log;

- Longer service life;

- When laying chopped wood, wind protection and anti-shrinkage technologies are used, which cannot be applied to rounded logs;

- Many types of corner placement are available. Among them are Finnish, Russian, paw, triple cutting and others;

- Natural material is quite aesthetic, therefore it practically does not require additional finishing.

DISADVANTAGES OF CHOPPED LOG

- Installation and installation of a log house are more complex, since they require precision and understanding of the principles of working with logs of different diameters;

- Manual work and labor-intensive processing mean a higher price;

- Different diameters result in a larger number of cracks that must be carefully caulked and sealed;

- The professionalism of the construction team directly affects the quality of the finished log house;

- The final shrinkage lasts about a year, the final result is 7-12%.

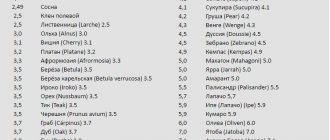

Average prices in the Russian Federation

Timber harvested in the northern regions has a higher price . For example, 1 cubic meter. Kirov pine costs on average from 7,000 to 8,000 rubles, depending on the diameter of the log, and Arkhangelsk pine costs from 10,000 to 13,000 rubles.

Chopped logs from the central part of the Russian Federation (Yaroslavl, Kaluga, Smolensk and Bryansk regions) can be purchased at an affordable price - from 6,000 rubles. for 1 cubic meter But when buying inexpensive timber, you should carefully check its quality, since you can purchase wood that is damaged by insects or infected with fungus.

Average cost of Arkhangelsk pine or spruce:

| Log diameter (mm) | Unit | Cost, rub.) |

| 220-260 | cubic meters | 12000-12500 |

| 260-300 | cubic meters | 12500-13000 |

| 300-400 | cubic meters | 13000-14000 |

ADVANTAGES OF CYLINDED LOG

- Like any wood, it is an environmentally friendly material that allows you to create ideal housing;

- Better fit of logs, which is due to the same diameter, increases thermal protection and sound insulation;

- The assembly and installation of a log house is significantly accelerated, since the technology does not require special skills and knowledge;

- The perfectly flat surface of the walls and floor allows any finishing to be done both inside and outside the premises;

- Light weight allows you to build log houses without massive foundations, which significantly speeds up the process of building a house;

- Natural material is quite aesthetic, therefore it practically does not require additional finishing.

DISADVANTAGES OF CYLINDERED LOGS

- Removing the top protective layer of wood significantly weakens the protection of the material. As a result, additional treatment with various antiseptics is required;

- Moisture absorption is higher; such wood may turn black or rot more actively without proper treatment;

- Wood that has been machined cracks much more;

- The log house needs proper processing and regular professional care in order to last much longer;

- Some laying technologies cannot be applied to rounded logs;

- The final shrinkage lasts about a year, the final result is 7-12%.

COMPARATIVE CHARACTERISTICS

| Characteristic | Rounded | Chopped |

| Appearance | The surface is flat and smooth, the shape and width of each log is the same. | The width and shape differs in each log, the surface is rough and uneven. |

| Diameter | The entire length of the log is the same, not exceeding 320 mm. | Different. The choice of sizes is quite wide, up to 520 mm. |

| Assembly | Due to the identical diameters and smooth surface, it is quite fast and simple. | Complicating the process due to different-sized logs. Requires additional skills and professionalism |

| Thermal insulation | The tight fit ensures high insulating properties and minimal heat loss. | A large number of gaps reduces the insulation characteristics. To live in a log house on a permanent basis, additional insulation is required. |

| Production | Mechanical. High production speed at the expense of loss of some protective properties. | Manual. The protective layer remains intact, but the production time increases. |

| Protective layer | Gets lost. Treatment with additional protective agents is necessary. | Saved. A basic impregnation against moisture and insects is sufficient. |

| Shrinkage | From 0.5 to 1.5 years. The result is 7-12%. | From 0.5 to 1.5 years. The result is 7-12%. |

Selection of quality logs

The quality of the finished log depends on the choice of truly high-quality material. You need to select the right material in advance, even before ordering construction. It is worth giving preference to winter forest, as it is considered stronger and more reliable. Before buying a tree, be sure to find out where and how the wood was harvested.

You are required to provide quality certificates; also check the storage conditions of the wood in advance. The ideal option is a company that independently procures materials and builds log cabins. The lack of in-house production means inflated prices for finished products. Also in this case it is impossible to check the quality of the wood.

For residential buildings it is worth choosing logs at least 240 mm thick; for northern regions it is better to choose at least 260 mm. Otherwise, in winter the room will be quite cold, which is not suitable for permanent residence. Country houses can also be erected from thinner logs.

controls the quality of materials that are manufactured in accordance with GOST standards. Timber storage, transportation and loading/unloading takes place in accordance with the rules for transporting timber and long cargo. This provides protection against damage and contamination of materials.

Thanks to its own production, the company controls every stage of timber harvesting. As a result, the quality of the products is confirmed by quality certificates and our storage conditions. Professionals from “SrubimBanyu” will quickly and efficiently install the log house. We also carry out a full range of finishing and communications work.

“Cut House Kirov” is a guarantee of the quality of logs and finished buildings

To get all the advantages of manual technology and not encounter the disadvantages, it is very important to choose a contractor responsibly. The labor intensity of production, the complexity of making corner joints, and laying crowns increase the requirements for performers.

By contacting a house-building company, you will receive quality guarantees for each of the works - from the choice of wood for harvesting to the final finishing touches. We:

- We harvest Vyatka pine forest and sort it according to GOST No. 9848 - we use logs with a dense, thin-ring structure that retains maximum thermal insulation properties;

- We check the layout down to the millimeter and control the assembly to eliminate “cold bridges” and cracks;

- We carry out all the work ourselves, without resorting to intermediaries and subcontractors - we bring building materials, pour the foundation.

We provide a guarantee for houses up to 20 years. When operating buildings, our company provides full maintenance and condition monitoring.