Wood structure

More than half (70–90%) of the volume of an adult tree is in the trunk. It is this that is the building material. More precisely, not the entire trunk, but only a certain part of it - wood. The trunk consists of several structural elements.

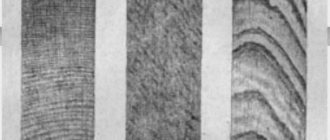

Main sections and main parts of the trunk - P - transverse, R - radial, T - tangential

Bark

It makes up from 6 to 25% of the tree’s volume and includes the bark (protects the trunk from sudden temperature fluctuations, penetration of fungi, bacteria, moisture evaporation, mechanical damage) and bast adjacent to the cambium. Bast conducts nutrients from the crown to the trunk and roots.

Cambium

This is a thin ring layer of living cells capable of dividing and growing. The greatest activity of the cambium occurs in spring and summer; during this period, an annual layer of wood is formed, consisting of early (spring) and late (summer) wood. Together this is one annual layer - the annual growth of wood. Summer wood is denser than spring wood.

Wood

This is the main part of the trunk; it carries water from the roots to the crown. Approximately in the center of the trunk there is a core, the diameter of which is 2–5 mm. Wood has an anisotropic structure, so its physical properties are different in different directions.

| See also: |

Aspen

When stored in a felled form, aspen wood acquires a white color with a slightly noticeable greenish tint. The cordate rays and annual layers are practically invisible. A distinctive feature of aspen wood is the almost complete absence of knots. It is highly resistant to moisture, does not warp, and practically does not crack. Aspen is easy to work with. It is soft, pliable, cuts well, pricks, easily polishes, and glues reliably. The disadvantage of aspen is its rapid drying.

The properties and structure of wood determine its use for the production of plywood, matches, dishes, toys and other small items.

Tree structure. From cells to roots

In this article, we decided to remind you what a tree is and talk about each of its parts: cells and tissues, wood and bark, branches and twigs, leaves and roots.

In many species of wood, there is a central dark-colored zone - the core and an outer light-colored zone - the sapwood . At an early age, all trees consist only of sapwood, but after some time (it is different for all species, and its width is also different) living elements begin to die off, blockage of water-conducting paths occurs and the deposition of extractive substances in the central part of the trunk - thus the core is formed in breeds called sound . These, for example, include: juniper, yew, pine, larch, cedar, oak, ash, elm, elm, walnut, willow, poplar.

In other breeds, the death of the central part is not accompanied by darkening. They have a uniform color of wood throughout the entire thickness of the trunk - such species are called coreless .

There is another type of species - mature wood , which have ripe wood in the central part of the trunk (drier than the rest). Their sapwood is the same color as mature wood. These include spruce, fir, beech, and aspen.

There are also rocks in which the central part does not differ from the peripheral part either in color or in properties - such rocks are called sapwood . These, for example, include: birch, linden, maple, hornbeam, etc.

In some deciduous trees, on a cross-section of the trunk, light shiny lines are clearly visible, diverging radially from the core - medullary rays. In radial directions they are visible in the form of narrow stripes, but are often invisible to the naked eye. They can be seen in oak, beech, maple and some other species.

Deciduous trees have water-conducting vessels that run along the axis of the trunk in the wood, and in the cross section only their sections of different shapes are visible. In some rocks they are large and clearly visible, forming rings. Such species are called ring-vascular - oak, ash, elm. Species with small, randomly located vessels are called scatter-vascular - birch, aspen, linden, maple, alder, beech.

Varieties

The widest range of lumber is presented:

- plates in the form of a half log obtained by cutting a tree trunk along the axis;

- quarters produced by sawing logs in two diameters. A perpendicular relationship is maintained, allowing cutting into 4 even parts along the axis of the workpiece;

- beams whose thickness and width exceed 100 mm;

- wood sleepers presented in the form of timber with a round cross-section. The main scope of application is the construction of railway tracks;

- boards up to 100 mm thick and no more than 200 mm wide;

- bars with a thickness of at least 100 mm and a length of less than 200 mm;

- slabs - wood waste obtained by sawing the side edges of logs;

- planks with dimensions: thickness - 60-80 mm; width - 100-160 mm.

Lumber

Properties of wood

In most species, the core has greater mechanical strength and a darker color compared to sapwood.

Sapwood has higher humidity compared to the heartwood zone and is less resistant to decay and insect damage.

Many conifers (pine, spruce, larch, cedar, etc.) have resin ducts, which are thin channels in the wood filled with resin. They are absent in fir, juniper, and yew. Resin increases the wood's resistance to rotting.

In accordance with GOST 20022.2-80, a classification of wood is established according to resistance to decay and impregnation with protective agents, the speed of depreservation and the vulnerability of objects of protection, as well as the classification of wood protective agents.

According to their resistance to decay, wood species (Table 1) are divided into 4 classes: resistant, medium-resistant, low-resistant and unstable, and the classification is carried out both by sapwood and core.

Table 1. Wood resistance to rotting

| Class | Wood type | |

| Sapwood | Core | |

| Persistent | Scots pine, ash | Siberian cedar pine, Scots pine, larch, oak, ash |

| Medium resistant | Spruce, Siberian pine, larch, fir | Spruce, fir, beech |

| Low-resistant | Birch, beech, elm, hornbeam, oak, maple | Elm, maple |

| Unstable | Linden, alder, aspen | Birch, linden, aspen, alder |

According to their impregnation with protective agents, wood species (Table 2) are divided into the following groups: easily impregnated, moderately impregnated, difficult to impregnate.

Table 2. Impregnation of wood with protective agents

| Class | Wood type | Wood type |

| Sapwood | Core | |

| Easy to soak | Scots pine, birch, beech | _ |

| Moderately soaked | Siberian cedar pine, European larch, hornbeam, oak, maple, linden, alder, aspen | Siberian pine, Scots pine, aspen, alder |

| Difficult to soak | Spruce, Siberian larch, fir | Spruce, European larch, Siberian larch, fir, birch, oak, elm, beech, ash |

Causes of rot

Photo: rot in microcosm!

Rot is just an advanced form of fungus and the development of dampness. In other words, if dampness had not appeared in these areas in your wooden house, then the development of rot would not have been possible. Therefore, you should look for the cause of dampness. Dampness in a wooden house can be due to many reasons, which we will discuss further.

Photo: as a result of the action of putrefactive fungi, the wooden beams of the house were completely destroyed.

The first reason for wood rotting is poor waterproofing of the foundation, or the wrong choice or absence of a backing board. The backing board must be laid on waterproofing and belongs to the species - larch. This type of wood is absolutely not afraid of moisture and is very durable. If you use a different breed, then most likely moisture will be transferred from the foundation to the crowns of the wooden house.

Photo: the last stage of wood decay - destruction and decay!

The second reason for dampness in a wooden house is an improper microclimate. In other words, you rarely ventilate your rooms, you have poor lighting, or, on the contrary, you ventilate your house very often and for a long time, which causes a lot of moisture to accumulate. Also, the presence of moisture can be indicated by the fact that you dry washed clothes in the house and do not close the doors of such rooms from where steam and moisture can spread.

The third reason why dampness may occur is the lack of basement ventilation. As a rule, dampness accumulates in such places first. Therefore, it is necessary to initially take measures to prevent this occurrence.

Photo: rot inside the log.

The fourth reason is the constant flow of water near your foundation. There are two striking facts about this problem. The first fact of damage is the effect of moisture on the foundation, through which dampness is transmitted to subsequent elements of the house.

The second striking fact is the effect of moisture that accumulates around the house on the most important first crowns of the log house. In other words, there is always high humidity around your house, so a low foundation is unlikely to isolate the lower crowns from moisture. To prevent this from happening, the lower crowns are usually made from more moisture-resistant rocks and treated with deep impregnation with an antiseptic. You can also make the foundation and soil flow diversions higher.

The fifth reason for rot is an improperly made roof. Something may be leaking, thereby creating dampness on the ceiling. This can be easily checked and eliminated with an active antiseptic from companies such as Neomid and Prosept.

Photo: treatment for wood rotting - Neomid 500 impregnation. You can order and buy it on our website here.

Photo: the most optimal price-quality treatment for rot-affected wood is the antiseptic bleach “Bioshield-2”. You can order and buy it on our website here.

The sixth reason for dampness is poorly sealed roof joints. The seams may be crooked, with gaps, poorly insulated, which will allow moisture to accumulate and transfer to the inside. All this can be avoided if you use effective inter-crown insulation, such as jute, tow, moss and produce high-quality caulk.

Density

Wood density (bulk density) is the ratio of wood mass to its volume, expressed in kg/m3. The density of wood depends on its moisture content. All indicators of the physical and mechanical properties of wood are determined at a humidity of 12%.

There is a close relationship between strength and density . Heavier wood is generally more durable. Density is determined by the amount of wood substance per unit volume.

Based on density at a humidity of 12%, wood can be divided into 3 groups:

- light density - up to 550 kg/m3 (balsa, Siberian fir, spruce, willow, pine, aspen, linden, alder);

- medium density – 551–700 kg/m3 (horse chestnut, walnut, birch, cherry, larch, teak, beech, oak, sweetener, sycamore, maple);

- dense species - from 771 kg/m3 and above (ash, plum, pecan, boxwood, persimmon, apple, olive).

The density of wood is of great practical importance. Denser wood is less saturated with antiseptics and is less susceptible to abrasion in places such as floors, stairs, and railings.

Walnut

Wood has a rich tonal range, as well as a variety of textures. Color varies from light brownish-gray to almost black. When freshly cut, the wood is light in color and gradually darkens over time. It is characterized by strength, moderate hardness, and high resistance to rotting. Keeps its shape, does not warp, and is easy to process. It is well polished, cut, glued and impregnated.

It is mainly used for finishing premises, furniture, hunting rifles, and for the manufacture of carved products.

Hardness

Hardness is the ability of wood to resist the penetration of harder bodies into it. The degree of hardness is influenced by the moisture content of the wood.

According to this parameter, all tree species at 12% humidity can be divided into three groups:

- soft - end hardness 40 MPa or less (pine, spruce, cedar, fir, juniper, poplar, linden, aspen, alder, chestnut);

- hard - end hardness 40.1–80 MPa (larch, Siberian birch, beech, oak, elm, plane tree, rowan, maple, hazel, walnut, persimmon, apple tree, ash);

- very hard - end hardness more than 80 MPa (white acacia, iron birch, hornbeam, dogwood, boxwood, pistachio, yew).

Hardwoods are more wear-resistant than softwoods. This is essential when processing with cutting tools: milling, sawing. And also when constructing floors, stairs, railings, since wood is subject to abrasion during use. In the production of parquet and solid wood parquet boards, rocks with a hardness of at least average are used.

Elm

It has a dark brown heartwood and yellowish-white sapwood. The material is durable, hard, dense, viscous. During the drying process it does not crack or warp. However, due to the too dense structure, permeated with small pores, the processing process (in particular polishing) of this material becomes significantly more complicated.

Used in carpentry work. When steamed, it lends itself well to bending, which is why it is used for the manufacture of curved parts. Burls on elm are especially valuable for turning crafts.

Strength

Strength is the ability of wood to resist destruction under mechanical loads. It depends on the direction of the applied load (tension, compression, bending, chipping), wood type, density, humidity, presence of defects and is characterized by tensile strength - the stress at which the sample is destroyed.

The average tensile strength along the fibers of all rocks is 130 MPa. The tensile strength along the grain is greatly influenced by the structure of the wood. Even a slight deviation from the correct arrangement of fibers causes a decrease in strength.

When stretched across the grain, the strength of wood is very low and on average is 1/20 of the tensile strength along the grain, i.e. 6.5 MPa. When compressed along the fibers, the deformation is expressed in a slight shortening of the sample. The compressive strength of wood across the grain is approximately 8 times lower than along the grain.

Pine

Pine is a type of softwood that is very easy to work with. It is easy to cut and drill . Pine usually has a light yellow coloration that can really brighten up any interior. Once treated, pine wood is very easy to stain if you want to give it a different tone. But the softness of pine is also its disadvantage, which leads to dents and scratches.

Pine is generally intended for indoor use unless it has been treated for outdoor use. It is widely known as one of the best woods for beginning woodworkers.

Depending on application

The properties of wood of various species are considered and compared depending on the type of product being manufactured.

Construction elements. The most popular types of building wood products are rounded logs, solid timber, laminated veneer lumber, structural beams, roof and ceiling building elements (boards and beams), frame elements, solid wood wall panels. For this category of products, the properties of wood such as strength and resistance to biological damage are important.

Floor coverings. Floor coverings are placed in a separate category, since today most enterprises are trying to ensure product quality in accordance with the requirements of European standards, which have a gradation not only in quality, but also in the appearance of the product (by the direction of the fibers - radial, tangential, mixed; by the presence of a nucleus, medullary rays, etc.). Floor coverings include: floor boards, parquet strips, parquet boards, deck boards.

This category also includes staircase elements (steps and railings). For this category of products, such properties of wood as hardness, density, shape stability, and abrasion are important.

Finishing materials, furniture and carpentry elements. Wood is widely used for interior and exterior decoration. For cladding a house, a board is used that imitates a rounded log or timber. For interior decoration, finishing boards (lining and eurolining), furniture panels for the manufacture of furniture, window sills, doors, wall panels and other elements of carpentry are widely used. For this category of products, stability of shape and wood density are important.

Other types of products. These are various board materials: chipboard, chipboard, fibreboard, MDF, OSB, etc.

In the next issue we will talk about the areas of application of coniferous wood.

____________________________________________________________________

Wood protection

How and from what should wood be protected? What new technologies can specialists offer?

Birch

The most widely used in industry is the warty birch. The species is coreless, has white wood with a yellowish or reddish tint. Characterized by good strength and toughness. Hardness and density are average.

The material is convenient to work with. It cuts and drills well, and is also easy to polish, glue and paint. However, despite all the positive properties of birch wood, there are also some disadvantages. It is practically unstable to rotting, dries out greatly, and warps. But this does not affect the demand for this material for finishing work, since the properties of birch wood make it possible to imitate various valuable species. The material is also used for the production of a number of other products (joinery, plywood veneer, lasts, skis, etc.).

Karelian birch wood has a very unusual texture. Broken heart-shaped rays, wavy growth layers and dormant buds in the form of dark stripes combine to produce a beautiful mottled surface. The material is used for the manufacture of artistic products and veneering furniture.

Yew

It has narrow yellowish-white sapwood and a brownish-red heartwood. The annual layers are characterized by a sinuous shape and are clearly visible in all sections. Yew is included in the list of species called “mahogany”. Hard, heavy, dense wood. The properties of wood are mostly positive. It is highly resistant to rotting. Good for processing, polishing and painting. It is considered one of the best materials used in finishing, turning and carpentry. Burls are very valuable, often formed on yew trunks and used mainly as a finishing material.

Juniper

The wood of the shrub is characterized by pinkish-white sapwood and yellowish-brown heartwood. It has wavy annual layers that are clearly visible on all sections. The heart-shaped rays are not visible.

The wood is strong and heavy. It is resistant to rotting, almost does not lose volume during the drying process and practically does not swell when interacting with moisture. The more dried the material, the more beautiful the cut. It lends itself well to processing, polishing and painting.

The use of the material is somewhat limited due to the small size of the bush trunks. Most often, juniper wood is used for carving, making decorative items, small crafts, toys, turning products, etc.

Linden

The wood is white, with a slight pinkish tint. Tree rings are practically invisible. It is characterized by a homogeneous structure and strength. The properties of linden wood, such as lightness, softness and toughness, make it possible to easily process the material in all directions, both manually and on a lathe. Paints well, sticks well, holds its shape. The wood is resistant to rotting and does not crack or warp during drying.

Due to its strong structure and low deformation, linden is used for making large parts of carved furniture. Drawing boards, pencils, dishes, etc. are also made from this material.

Siberian cedar

The wood is pinkish in color with a beautiful grain pattern. Tree rings are clearly visible in all sections. It is light and soft. In terms of technological properties, cedar is inferior to pine, but superior to spruce. The material can be easily processed, but is not very resistant to rotting.

Cedar wood has resonant properties, which is why musical instruments (guitars, harps, grand pianos) are made from it. In addition, it is used for the manufacture of furniture, in the production of pencils, etc.

Alder

The natural color of alder wood varies from white to pale brown. After the log house, as a result of interaction with air, it changes to red-brown in a short time.

Wood is not particularly durable and can warp when dried, but it has a number of positive technological properties, as it is characterized by lightness, moderate hygroscopicity and softness. Can be cut, polished, glued and painted without any problems. It has no odor and does not absorb foreign odors. It is highly resistant to rotting, which is why it is often used to equip wells and storerooms. In addition, it is used for carving and finishing work. The physical properties of alder wood make it possible to imitate certain wood species (for example, mahogany and ebony).