Modern power tools are easy to use, but few people know all of their functions.

For example, a suitable sanding drill attachment can be used to make it easy to handle tedious work without spending a lot of effort on it.

Since there are all kinds of drill attachments, we suggest you take a closer look at them.

Advantages and weaknesses

Many manufacturers produce sanding attachments, but not all make sure that the product is reliable.

In competition, preference is given to making products cheaper, so quality suffers.

A third-rate tool will not last long, so you should not focus on the minimum cost. Although the price of high-quality attachments may vary significantly, such a purchase will still be less expensive than purchasing a special tool. Let's pay attention to some criteria.

Advantages

- In some cases, only with the help of this device can you sand a hard-to-reach surface area.

- Convenient for cleaning small parts.

- Devices for an electric drill are cheaper than specialized tools and accessories.

- You can make many sanding attachments yourself.

Flaws

- The device is less convenient to use than a specialized tool.

- You won't be able to work with some attachments without some skill.

- Poor performance.

- Sometimes you can’t do without a drill with adjustable chuck rotation speed.

Since the benefits are more significant, the attachments are popular and used by many people.

Where can it be used

Depending on the type of sanding attachment you purchase, you can use it to:

- clean metal from rust;

- remove paint from iron;

- polish metal;

- polish painted surfaces;

- polish wood parts exposed with varnish;

- polish glass;

- grind the edge of the glass;

- grind small parts;

- remove scale, burrs from metal and correct other defects in places where it is not possible to do this with another tool;

- perform grinding of products in places where grinding cannot be done with another tool.

This is an incomplete list that could be expanded.

Materials from which nozzles are made

All grinding attachments have one property in common: impact on softer material with the ability to scrape it off. But different jobs may require different rigidities. The following materials are used for nozzles:

- sandpaper;

- fabric materials or soft fibers;

- stones.

Sandpaper is used in the vast majority of work, as it allows you to process the surface with different forces, depending on the grain size of the material. Cloth or soft fibers are used for final polishing. Stones can be useful if it is necessary to make major changes to the shape of a part.

What types of devices are there?

Unlike attachments for grinders, any device for a drill is equipped with an axis fixed in the chuck.

Plate

Most drill grinding attachments are made of plastic. They are primarily intended for use in an angle grinder, but thanks to the adapter they can be mounted in a tool chuck.

This type of fastening is rigid and therefore not applicable in all cases. For example, even with a slight displacement of the nozzle, its edge can bite into the surface being sanded, leaving deep grooves.

For this reason, it is more convenient to use a hard plastic attachment by holding the drill still, as in the following illustration.

A rubber attachment is more convenient when working with a drill - thanks to its flexibility, accidental damage to the surface being worked is eliminated when the drill is tilted or pressed excessively.

Another type of similar grinding tool is made with a movable pin mount, but due to the high cost of the latter, it is not in great demand.

Cup

Structurally, the cup attachments are practically no different from each other, but the brush itself can consist of metal (steel, brass) wire or polymer abrasive bristles.

Each brush has a certain hardness and is used strictly for its intended purpose, established by the manufacturer - you can grind metal (removing traces of corrosion), wood and other materials.

Working with such a tool is fraught with some difficulties - by choosing the wrong angle, you can ruin the soft material being processed, and the drill itself constantly strives to move to the side when pressing the device over its entire area.

Disk

These attachments are similar to cup attachments, but the direction of the bristles is different - to the sides. Most often they are used when it is necessary to process material in hard-to-reach places.

Drums

This device resembles a drum in appearance, and thanks to this similarity it received the name of the same name. Such a drum attachment is a cylinder with sandpaper attached to the outer wall.

This device is secured by tension with a special bolt or fixed by pumping with compressed air. When using an open belt, tension is created by a rotating screw that pulls on the sandpaper.

With the help of drum attachments, it is not difficult to sand parts made of wood and metal. A grinding attachment with fine particles of abrasive material can be used when processing the edge of glass. Very convenient for grinding round and oval holes.

Fan

This attachment is made in the form of a disk with fixed fragments of abrasive material. This feature of the tool significantly expanded the range of sizes of processed parts, grinding the cavities of small and large holes. Thanks to the flexibility of the blades, parts of various shapes can be sanded.

End

Such nozzles have different shapes, and the working part can be made of various materials.

Designed for starting or finishing processing of holes and the inside of shaped workpieces. Jewelers and dentists use similar devices, only in miniature size.

Soft

When polishing a workpiece, round foam rubber, felt or leather attachments fixed on an axis can be used. Such a device wears out quickly; it can be used to polish metal or a coating exposed by varnish/paint to a mirror shine. The device is matched directly to the material being polished.

Read also: How to restore an electric motor armature

Device for converting a drill into a circular saw and grinder

A special adapter can turn the drill not only into a real circular saw, but also into a grinder.

The device consists of a clamp that securely fixes the drill, a mount for a gear wheel or grinding wheel, and a platform measuring 75 × 85 × 11 mm, which is screwed to the surface of the work table.

All adapter parts are made of metal and are particularly durable.

Having such a device in his arsenal, the master, in addition to the drill, receives two more useful tools: a circular saw and a grinder.

Price - about 800 rubles.

9

Homemade devices

It is not only the desire to save money that drives a person when creating a homemade nozzle - sometimes the necessary device simply cannot be purchased, and then one has to design and invent it. In this section we will show several options for attachments that can be made at home using improvised materials.

Based on Automotive Valve

To make such an attachment you will need one or more flat bottom car valves. It is better to make a larger nozzle from a truck exhaust valve.

The surface must be degreased and a head of the desired shape must be glued, which can be made of wood, dense foam, rubber and other suitable material, and then glued to the valve with epoxy or polyurethane glue.

Now you need to cut out circles from sandpaper. The nozzle turned out to be 5.5 cm wide - cut out the same circle for it.

Not reaching the center, cuts are made on the sides and adjusted so that each petal overlaps the other (as this device rotates).

Hot melt adhesive was used to glue the sandpaper.

After gluing the sandpaper, the edges of the petals were secured with staples.

The nozzle did an excellent job, but it quickly clogged because the sandpaper used was fine-grained.

Hence the conclusion - you need to make several attachments so that you can perform different types of work.

Tips for choosing

In a good half of cases, grinding attachments are sold under the brand name of electrical equipment manufacturers. It's good if both devices are of the same brand. Then there shouldn't be any compatibility problems.

It is better to look towards well-known brands. They care about quality due to high competition in the market. Although products from no-name manufacturers are much cheaper, the chance of running into a mediocre product in this case is much higher.

Popular manufacturers:

- "Bosch"

- "Makita";

- Dremel

- "Bison";

- "Matrix";

- Fit;

- "Enkor";

- Verto.

It makes more sense to overpay for quality than to constantly buy waste grinding attachments that wear off after several uses.

Simple screw device

To make this attachment you will need a long screw, 2 washers, a nut, and several pieces of sandpaper.

A washer is placed on the screw. After cutting the sandpaper into squares, a hole is made in the middle, and all the pieces are put on the screw. Then comes the turn of the second washer, and this entire set is clamped with a nut.

By inserting the device into a drill, you can grind the cavities of wooden parts with it.

The disadvantage of such a device is that the threads are jammed by the drill chuck, which creates a problem with re-applying sandpaper. The unnecessary part of the thread can be removed or 3 slots can be made on the screw - our homemade device will be clamped with a drill chuck.

Polishing device

As in the previous case, we will need a screw, washers and a nut, only felt will be used instead of sandpaper. Having marked a piece of felt, cut out circles of the same radius from it.

Holes are made in the center of the workpieces, they are threaded onto a screw, and then clamped with a nut. The finished device is inserted into the drill chuck.

Felt alone will not polish the part, so after turning on the drill, rub the attachment with Goya paste. After this you can start working.

For the purity of the experiment, an old and rusty wrench was used. As you can see in the photo, after a short polishing, the treated area was effectively cleaned in a short period of time.

This polishing attachment can work with both flat and shaped parts, but it will not cope even with small recesses.

Leather circle

As in the device described above, leather can be attached instead of felt, resulting in a device for straightening wood cutters.

We use a file

A round file can be used as an attachment by removing the handle from it and holding the shank in the chuck. It is better to secure a file of small diameter to the base.

Using this device, it is convenient to grind holes and semicircular depressions.

Epilogue Regardless of whether you use a purchased drill attachment or make one yourself, it can be an invaluable assistant in many jobs.

The main purpose of a drill when working with wood is to drill holes. However, this tool is much more functional than many people think. To expand its functionality, special wood attachments are used, which, in fact, is the subject of this article.

Electric drill with attachment

Next, we will look at what drill attachments exist for woodworking and for what purposes they are used.

Types of nozzles

Not everyone knows that with the help of attachments, in addition to drilling holes with a drill, you can perform many other operations, such as:

However, it should be said right away that attachments are not a complete replacement for special equipment. The quality of operations performed with their help is inferior to individual instruments. However, in some cases they can significantly simplify wood processing with your own hands.

Below we will take a closer look at all types of attachments for performing the above work.

Drill Drum Attachment for Sanding Wood

Sanding and polishing

There are many types of attachments for grinding and polishing wooden surfaces, the main ones are listed below:

| Type of transaction | Types of nozzles |

| Grinding | Nozzles of this type are a rod with a grinding material attached to it, which can be used as: |

- Sandpaper;

- Special brushes;

- Rigid fabric such as felt.

According to the type of design and shape, grinding heads are of the following types:

- Disc discs - made by analogy with discs intended for conventional grinding machines, the only thing is that instead of threads they have a pin for fixing in the chuck.

- Cup - they are a cup with a brush. They are usually used for removing old paint from wood and other rough treatments.

- Drum type - they are a cylinder with sandpaper attached to the walls. Such heads can be used to process the surface inside the holes, as well as the end of the boards.

- Petal – a large number of sandpaper petals are attached to the rod of this tool. With the help of such attachments, radius grinding of wood with a drill can be performed, as well as processing of parts with complex surfaces.

Read also: How to connect a bactericidal lamp to the network diagram

Based on the degree of softness, polishing tips are divided into the following types:

In addition, they can vary in shape and size, which allows you to choose the most optimal tip for polishing a particular type of surface. For example, conical and thin cylindrical nozzles can be used to polish holes.

Felt tips for polishing

The choice of nozzle in this case depends on the operation being performed. For example, if you need to sand a surface in a hard-to-reach place, an excellent option is a sanding attachment on a drill for petal-type wood. If you need to clean the surface from paint or renew it, you should give preference to cup attachments.

Making large diameter holes

To make large diameter holes, several types of nozzles are used:

- Feather drills - thanks to the flat cutting part and special sharpening, they allow you to make holes in wood, chipboard, plywood and OSB with a diameter of up to 60 mm. It should be noted that feather drills are available not only for wood, but also for metal.

Attachment with a set of wood crowns

- Wood drill bit – allows you to drill holes in wood with a diameter of up to 100 mm.

- Forstner drill – has a centering tip. Using such a drill, you can make blind holes, for example, for installing hinges in furniture making.

In the photo - Forstner drills

Advice! When making holes in chipboard and other similar materials, do not press the drill too hard, as this can lead to chips and cracks.

It must be said that there are special devices on sale that allow you to change the drilling angle. Their purpose is to provide ease of drilling in hard-to-reach places.

Cylindrical wood cutter for drill

Milling

With the help of special tips, the drill can even be used for milling wooden parts.

There are different types of cutters (cutters):

- Cylindrical;

- Face;

- End;

- Disk;

- Shaped, etc.

The choice of cutter depends on the type of operation being performed. For example, if it is necessary to make grooves in a part, use disc cutters for wood drilling. To make complex cuts, it is better to use shaped cutters.

It should also be noted that cutters differ in the shape of the teeth, which are:

- Pointed;

- Backed.

The good thing about backed teeth is that, if necessary, they can be resharpened, while pointed teeth cannot be restored.

Wood cutting attachment

cutting

The attachment on a drill for cutting wood is a rather complex mechanism that works on the principle of a jigsaw. It can be used to cut wood up to 20 mm thick, as well as plywood and chipboard.

In addition, the attachment can be used to cut plastic and even steel. Thus, this device will be useful to every home craftsman, unless, of course, there are special tools for cutting a particular material.

However, it should be noted that the price of such a nozzle is quite high, which is explained by the complexity of its mechanism.

Advice! Before making an internal cut with a jigsaw attachment, you need to drill a hole with a diameter equal to the width of the file.

Nozzles for screwing in self-tapping screws

Screwing in self-tapping screws

The nozzle for screwing in self-tapping screws is the simplest type of tip. However, it should be noted that it can only be used with those types of drills that have a speed reduction option.

These products are usually sold in sets containing heads of several diameters. This allows you to work with self-tapping screws and screws of different sizes.

Here, perhaps, are all the most common types of nozzles. It must be said that there are also less popular tips, for example, flexible drills on cables, which allow you to make holes in hard-to-reach places, as well as angle attachments, which allow you to turn a drill into an angle grinder. True, they can be found on sale much less often.

Drill with angle attachment

Basic rules for working with a drill and attachments

When using an electric drill, like any other power tools, the operating instructions and safety regulations must be strictly followed.

Below are the main ones:

- Before processing, the workpiece must be securely secured.

- The nozzle must be securely fixed in the cartridge. If there is play, it is prohibited to work with it.

- When working with a drill, it must be held with both hands, especially for powerful models.

- The pressure should not be excessive.

- It is forbidden to turn on the reverse mode until the drill has stopped completely.

- When working, you must use personal protective equipment - gloves and goggles.

- After completing the work, do not touch the drill or other tip for some time, as you may get burned.

Note! You should not try to make a nozzle or adapter yourself. The fact is that electric drills operate at high speeds, as a result of which a poor-quality or unbalanced attachment can cause injury.

Observing these simple injuries will make the work safe, which is the most important thing when performing any construction operations.

Read also: How to draw an electrical diagram

Dry and wet sanding

How to properly sand wood with a sander or other tool? First, it is important to choose the type of procedure. It can be dry or wet. The first type increases the effectiveness of the abrasive and ensures its accurate removal. The downside of this technology is that the skin easily becomes clogged with dirt.

When carrying out wet sanding, you need to apply the liquid to the grainy surface of the sandpaper. Mineral oil or soap solution can be used for this. White spirit will also work.

Note! During the wet procedure, the abrasive becomes much less clogged, which helps to increase its service life. This creates an unpleasant mass of foam and shavings.

Conclusion

Thanks to the large number of woodworking attachments available, the drill is one of the most functional tools. It especially makes sense to use all kinds of tips in cases where the need to process wooden parts arises only from time to time. Of course, for frequent and especially professional work, it is necessary to purchase separate tools.

You can get some additional information on the topic discussed above from the video in this article.

The use of special devices clamped in the chuck of this power tool makes it truly multifunctional. For example, you can even cut sheet iron with it. Considering the variety of drill attachments for woodworking, it is unrealistic to go into detail about each of them in one article. We will deal only with attachments that allow using a drill to perform high-quality and quick surface mechanical processing of wood.

What is it? Preliminary cleaning of the surface (rough), removal of burrs, grinding and bringing to a mirror shine (polishing). All other technological operations with wood - milling, drilling, screwing in fasteners, cutting - do not belong to the concept of “processing”. This is what the author proceeds from. The difference in the listed types of work in relation to attachments is in the rotation speed of the drill chuck and the type of device. Which one to choose is decided mainly based on the required degree of processing of the tree and its species (that is, the density of the structure).

How to make a nozzle with your own hands

Making accessories for a drill with your own hands is not difficult. Any available means are suitable for this. You can make a wire brush attachment using a piece of pipe and a piece of metal cable.

The manufacturing process consists of the following stages:

- Cut off a piece of thin metal pipe. The length is chosen arbitrarily. To clean internal cavities, it is recommended to choose the following workpiece parameters: diameter – 10-20 mm, length – about 20 cm.

- Make through holes in the upper part of the pipe at a distance of 1-2 cm. You will need 4-5 of them. The diameter of the drill is selected taking into account the thickness of the cable.

- Cut the cable fragment into 4-5 pieces of equal length. The size is selected taking into account the diameter of the pipe (5-8 cm).

- Thread the pieces of cable into the holes made in the pipe. The parts must fit tightly into the channels. Equal releases are made on each side.

- Flatten the end of the tube on the side where the holes are made with a hammer.

- Using pliers, release the cable.

The result is a brush with wire bristles. Such equipment can efficiently clean places where access to the tool is limited. These are mainly pipes of different diameters, cavities and recesses. Fix the attachment into the drill chuck, and the equipment is ready for use!

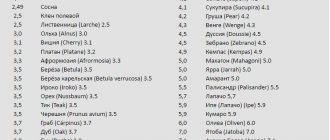

Classification of attachments for wood processing

Prices are indicative, in relation to the Moscow region, in Russian rubles

By type of abrasive

- Hard fabric.

- Foam rubber.

- Plastic.

- Sandpaper of different grain sizes.

- Rubber.

- Cord brush.

According to the degree of wood processing

- Abrasive (rough).

- Grinding.

- Polishing pads (soft and super-soft pads).

By execution

Depending on the configuration, the attachments are used not only for surface treatment of wood. They can be used to grind (polish) holes (as a replacement for a sander). This is easy to do with cylindrical (thin) or conical devices.

Plate attachments

Available in several modifications. The difference is in the form of abrasive material. If wood sanding is required, then it is rubber (the more preferable option) or plastic. For polishing, it is advisable to purchase attachments with fine-grained sandpaper fixed on the working part. They can achieve higher quality (fine) wood processing.

Recommendation: Effective processing of wood with a plate-type drill attachment is difficult because it is difficult to hold the drill in a strictly vertical position. To achieve a good result, it is advisable to fix the tool and move the workpiece relative to the working part. The machine for attaching the drill is easy to assemble yourself.

There are nozzles on sale that provide for adjusting the angle of the abrasive mounting pin. But they are quite expensive, and not every store can buy them. Therefore, a machine with the ability to change the position of the drill is a more acceptable solution.

Drum attachments

Mainly used for processing the end parts of wooden workpieces and holes. They have a cylindrical shape and differ in the way the sanding tape is attached - using a bolt or special inflatable blocks. Some types of attachments of this type are also used in everyday life for plucking (at low speed) birds when it comes to a large amount of work.

Cup attachments

The assortment is significant. The differences are in size and abrasive material. These can be either metal “hairs” (hard wire) or thick fabric, leather, felt and even foam rubber. The choice of device is determined by the desired degree of wood processing. If you want to achieve a sharper highlighting of the texture of the material, then the wood pulp is sampled using just such attachments.

A variety of devices in this group are disk attachments. The difference is clear from the figure (the villi are located diametrically).

This type of attachment can also include fan devices. They are also called petal.

The main purpose is to polish wood at the final stage of processing.

Briefly about the main thing

A drill is a versatile tool that is easy to grind, polish and clean surfaces. To do this, just buy special attachments.

The advantages of grinding attachments include the ability to save on the purchase of unnecessary equipment and ease of use. Their disadvantage is lower speed and low productivity compared to professional tools.

Nozzles are divided into several types: cup, plate, drum and others. Each type is suitable for certain jobs, for example, hard plate attachments work well with preliminary processing of wood, softer ones - with final processing.

You can work with attachments in two ways: move a disk over the surface or attach a drill and bring the object to it. The first option is suitable for large surfaces, the second - for small parts.

What to consider when choosing drill attachments

- Using attachments, for example, the same grinding attachments, you can process not only wood, but also other materials - metal, glass, ceramics, and so on. You just need to select the appropriate modification of the device.

- According to reviews from practitioners, identical attachments from different manufacturers can differ greatly in effectiveness and duration of use. Therefore, you should not save on purchasing products from a little-known brand. It is not a fact that such a device will not become unusable after short-term use.

- Even an expensive attachment will cost much less than a special power tool. For example, a grinding machine, for which you will also have to additionally purchase the appropriate accessories (blade, wheel, etc.) depending on the type of product.

- When choosing any attachment, you should focus on the following features of your electric drill: power, chuck size, ability to regulate speed. Otherwise, the ease of use of the device and the high quality of wood processing are not guaranteed.

The article discusses the main types of drill attachments. Each group is available in several modifications; In addition, manufacturers regularly supply some new products to the market. Therefore, the choice of size, configuration, and abrasive must be made for a specific technological operation, especially since it exists and is quite large. This can achieve the highest quality results in wood processing. Considering that it is impossible to foresee everything, especially without extensive practical experience in working with nozzles, it is better to purchase them in specialized stores. Based on the characteristics of the buyer’s drill, the seller will help make the best choice.

| Polishing | Polishing attachments resemble the heads described above, the only difference is that the filler is made of soft materials, which means they provide a finer surface finish. Most often, these products take the form of a disk made of soft material on which foam rubber, felt, felt or other soft filler is attached. |

What and how to grind

If you need to process wood, you need to choose the optimal tool. The following features should be taken into account:

- Type of product. These can be load-bearing structures made of timber, windows and doors, furniture parts, and decorative elements. Each product has an optimal option that allows you to achieve maximum quality with a minimum of time and effort.

- Sanding quality. This is quite an important factor. In some cases it is enough to smooth out large roughnesses, in others it is enough to bring the surface to perfection. Therefore, before starting work, it is important to prepare brushes and discs that have different grain sizes.

- Scope of work. Small structures can be handled manually, but large ones require a power tool.

The following devices are used for sanding wood:

- Bulgarian;

- drill;

- surface grinder;

- belt sander;

- hand tool.